Lens structure of micro-lens driving device and manufacturing method thereof

A lens driving device, lens structure technology, applied in installation, color TV parts, TV system parts and other directions, can solve the problems of threaded structure occupying volume, focus out of focus, excessive power consumption, etc., to solve the problem of contact The effect of friction loss, reduction of defective products, and volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

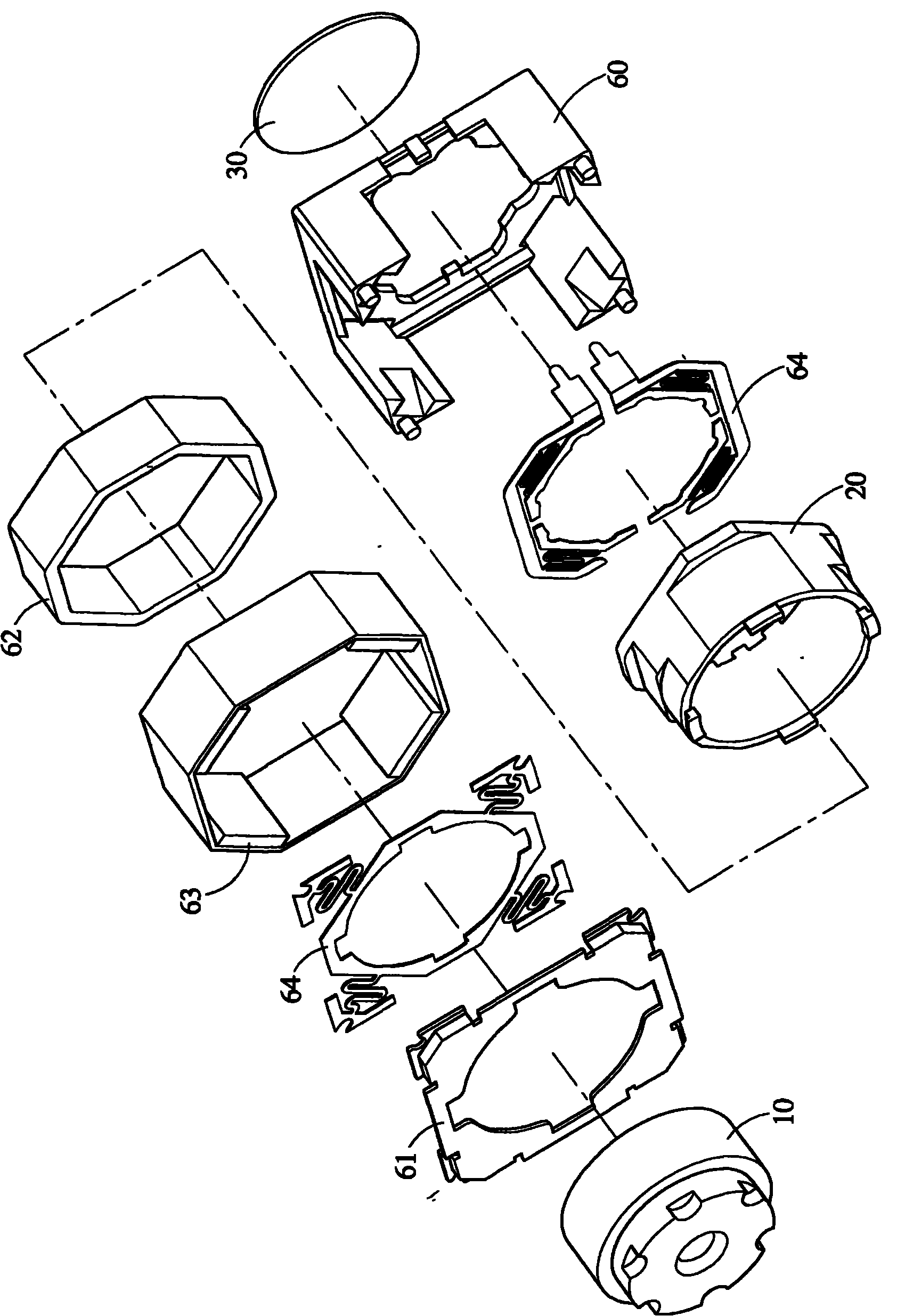

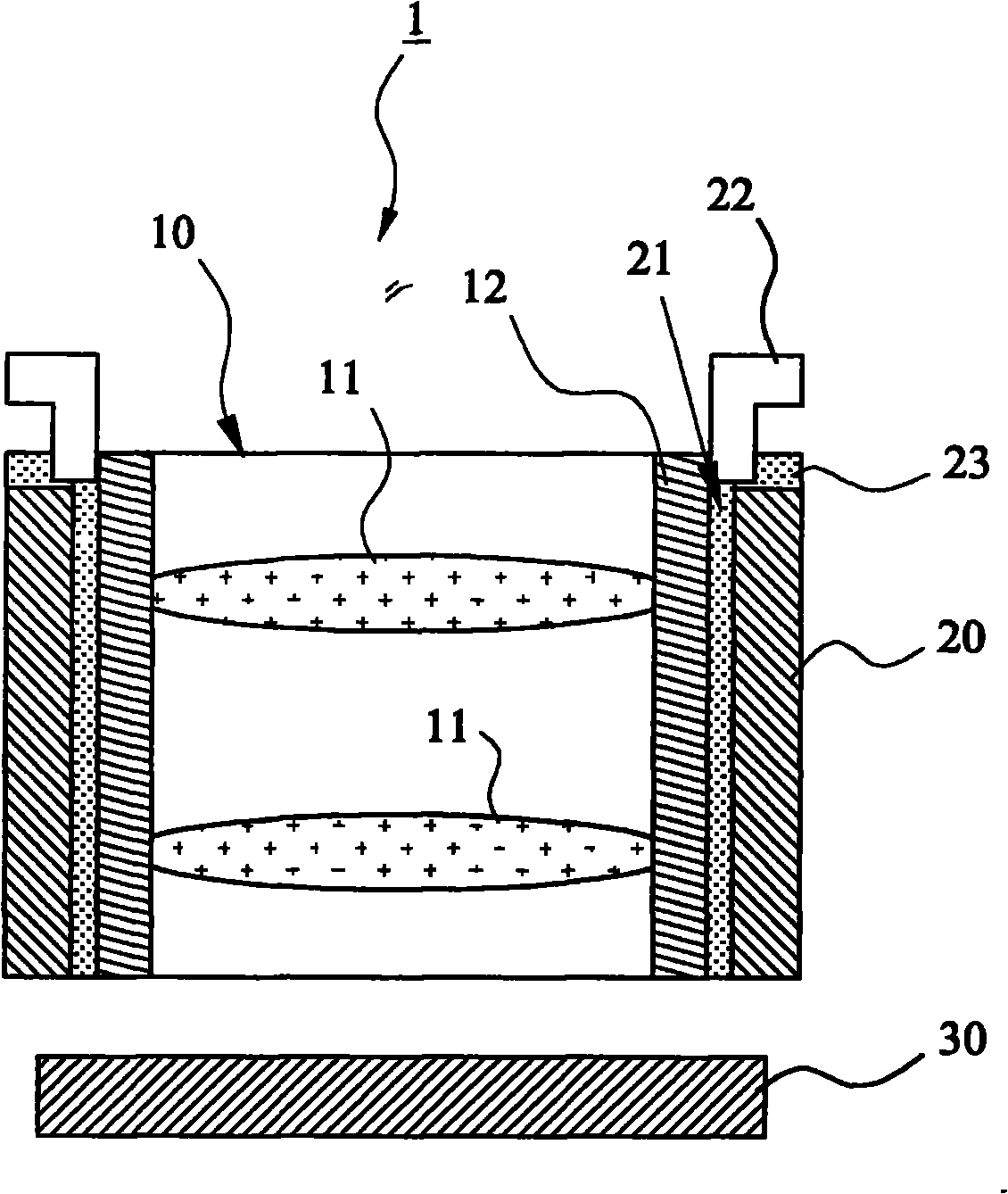

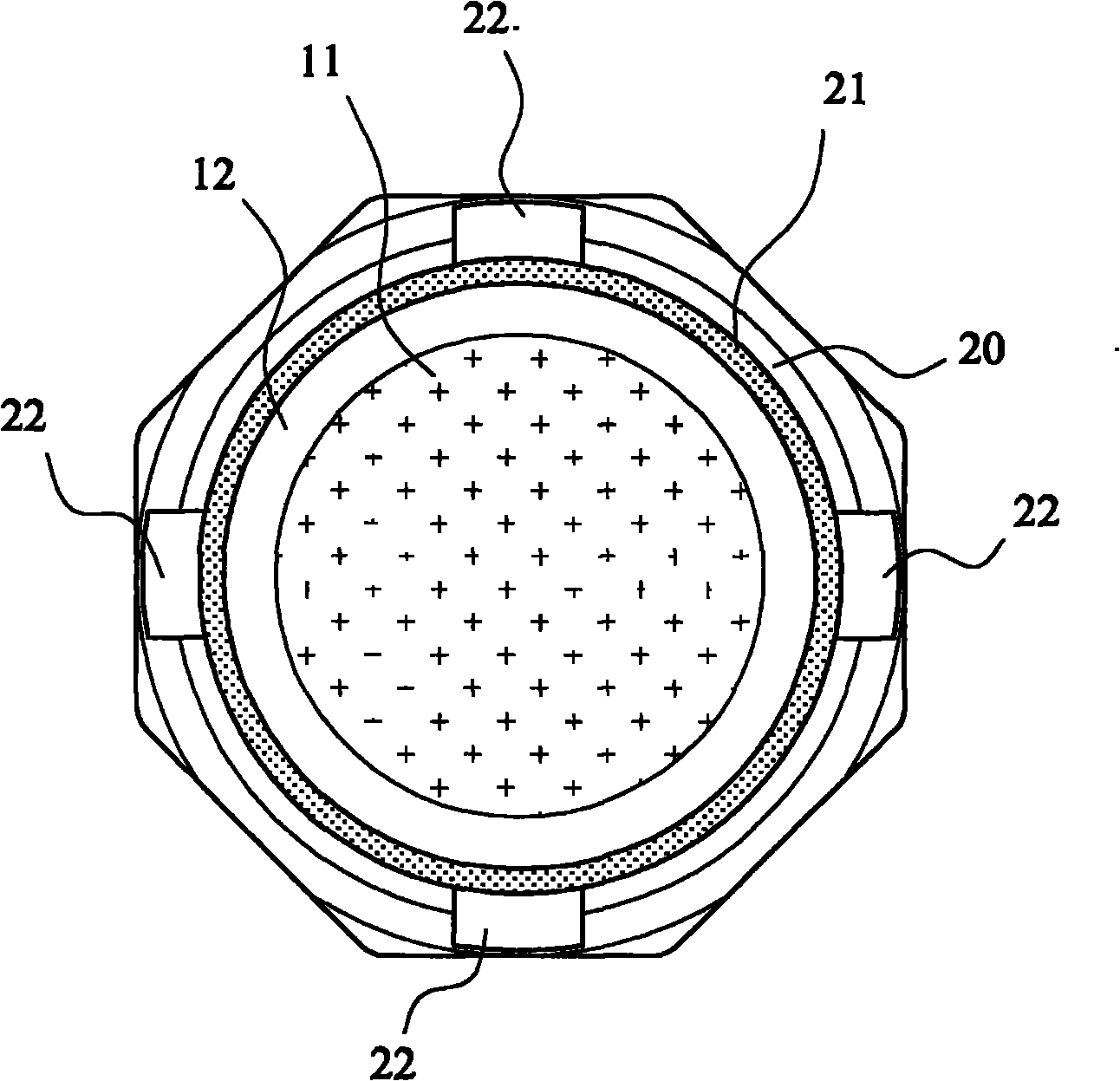

[0038] see figure 1 As shown, it is a three-dimensional schematic diagram of an embodiment of the lens driving device of the present invention. The lens driving device of this embodiment includes a bearing seat 20 for carrying a lens cylinder 10, and the bearing seat 20 is accommodated in a frame 60 of a hollow structure. , the frame 60 can also be covered with an upper cover 61, and the periphery of the bearing seat 20 is covered with a coil assembly 62, and four permanent magnets 63 are arranged outside the coil assembly 62 corresponding to the coil assembly 62. On the bearing seat 20 A set of elastic components 64 are connected to each of the bottom and the bottom, which can suspend and support the bearing seat 20 in the center of the frame 60 , and an image sensor 30 is arranged below the frame 60 .

[0039] The coil asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com