Anode material for lithium-ion battery and preparation method

A technology of lithium ion battery and negative electrode material, applied in battery electrodes, circuits, electrical components, etc., can solve the problem of low specific capacity of lithium titanate, increase reversible specific capacity, mild conditions, improve high rate performance and low temperature The effect of electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

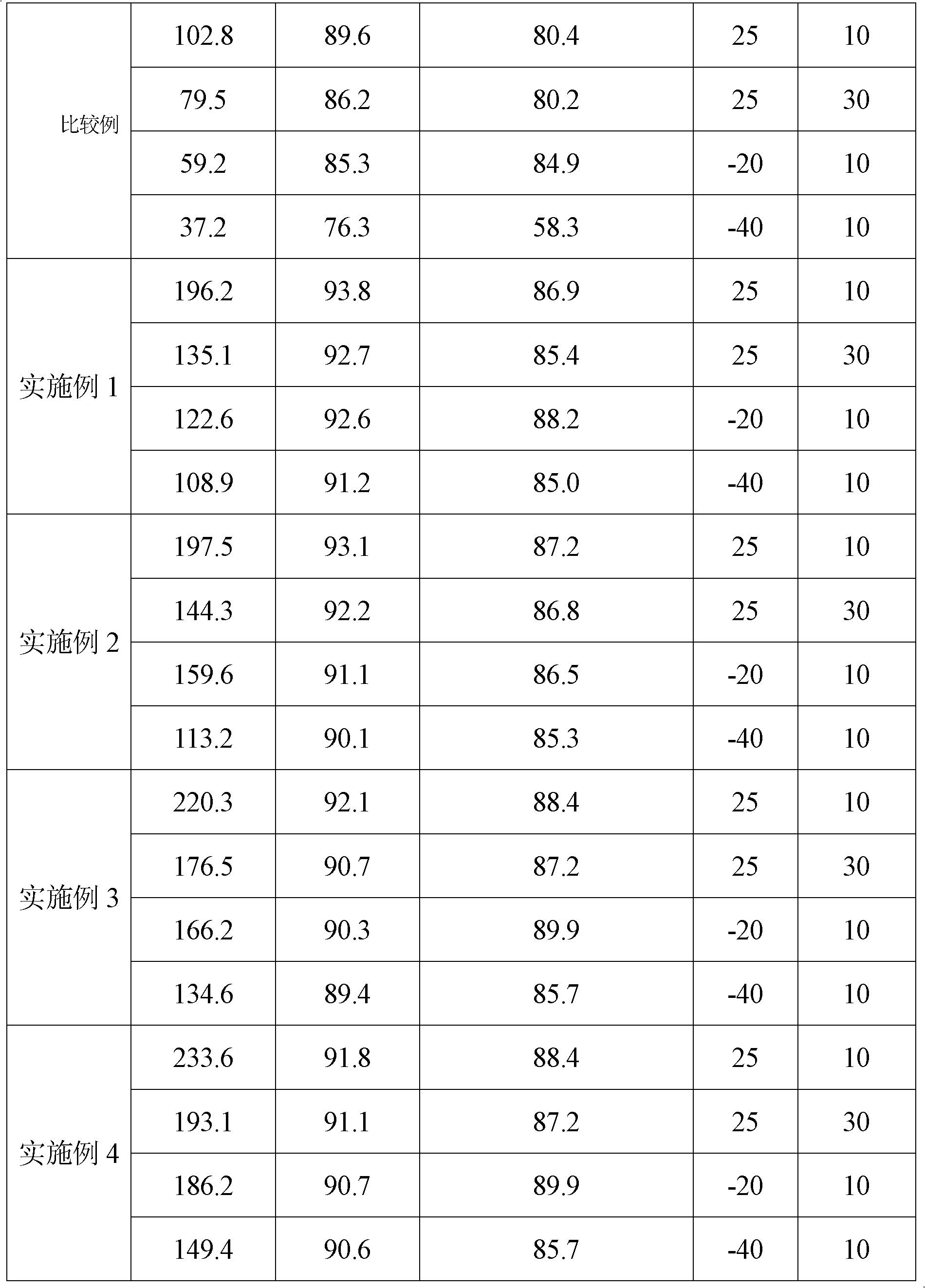

Embodiment 1

[0020] Lithium-ion battery composite negative electrode material is composed of graphite and mesoporous carbon. The mass percentage of mesoporous carbon in the composite material is 2.5%; the degree of graphitization of graphite is 80%; the pore size distribution of mesoporous carbon is 2-50nm. The porosity is 92%; the D50 (particle diameter of 50% of the particles accumulated) of the composite material is 10.973 μm, and the D90 (particle size of 90% of the particles accumulated) is 23.892 μm.

[0021] The preparation method of above-mentioned composite negative electrode material is as follows:

[0022] Step 1: graphitize the coal tar pitch coke at 2100° C. for 2 hours to obtain graphite with a degree of graphitization of 80%.

[0023] The second step: the graphite obtained in the first step is pulverized by a crusher, classified, and air-flow milled to obtain fine graphite with a D50 of 4.331 μm.

[0024] The third step: uniformly mix fine graphite, phenolic resin (residual...

Embodiment 2

[0026] The lithium-ion battery composite negative electrode material is composed of graphite and mesoporous carbon, and the mass percentage of mesoporous carbon in the composite material is 3.9%; the degree of graphitization of graphite is 83%, and the through-porosity of mesoporous carbon is 93%; the composite material D50 is 7.881 μm, and D90 is 18.841 μm.

[0027] The preparation method of the above-mentioned carbon composite negative electrode material is as follows:

[0028] Step 1: graphitize the petroleum coke at 2400° C. for 4 hours to obtain graphite with a degree of graphitization of 83%.

[0029] The second step: the artificial graphite obtained in the first step is pulverized by a crusher, classified, and air-flow milled to obtain fine graphite with a D50 of 3.179 μm.

[0030] The third step: uniformly mix fine graphite, phenolic resin (40% carbon residue rate), and pore-forming additive F127 in 60ml of ethanol solvent according to the mass ratio of 99:10:5, and s...

Embodiment 3

[0032] Lithium-ion battery composite negative electrode material is composed of graphite and mesoporous carbon, and the mass percentage of mesoporous carbon in the composite material is 28.8%; the degree of graphitization of graphite is 87%, and the through-porosity of mesoporous carbon is 86%; the composite material D50 is 14.881 μm, and D90 is 28.841 μm.

[0033] The preparation method of the above-mentioned carbon composite negative electrode material is as follows:

[0034] Step 1: graphitize coal tar pitch coke at 2700° C. for 5 hours to obtain artificial graphite with a degree of graphitization of 87%.

[0035] The second step: the artificial graphite obtained in the first step is pulverized by a crusher, classified, and air-flow milled to obtain fine graphite with a D50 of 5.279 μm.

[0036] The third step: uniformly mix fine graphite, phenolic resin (40% carbon residue rate), and pore-forming additive P123 in 60ml of ethanol solvent according to the mass ratio of 99:1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com