Manufacturing method of packaging base plate provided with side surface lines

A manufacturing method and surface circuit layer technology, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve problems such as difficulty, high manufacturing cost, and difficulty in improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the above objectives, features and advantages of the present invention more obvious and understandable, the following is a detailed description of the preferred embodiments of the present invention in conjunction with the accompanying drawings:

[0027] The method for manufacturing a package substrate with side surface circuits of the first embodiment of the present invention is mainly used to manufacture single-layer or multi-layer circuit substrates for semiconductor packaging, and can be further used to construct various package structures with substrates For example, ball grid array packaging (BGA), pin array packaging (PGA), contact array packaging (LGA), or chip-on-substrate packaging (BOC), etc., but not limited to these. The present invention will cooperate below Figure 1A to 1E The specific technical content of each step of the first embodiment is described in detail one by one.

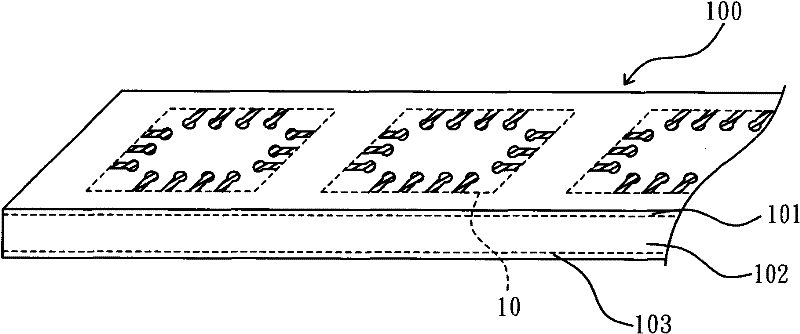

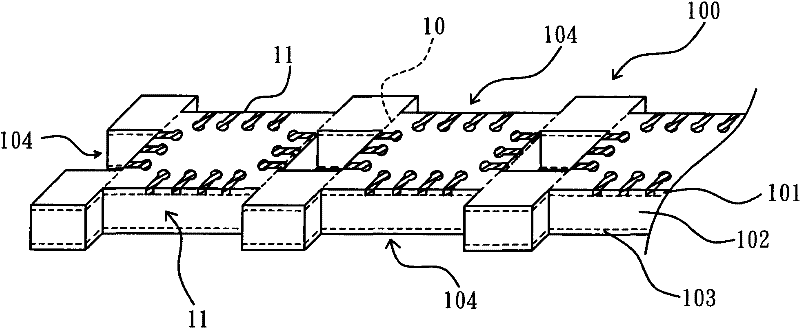

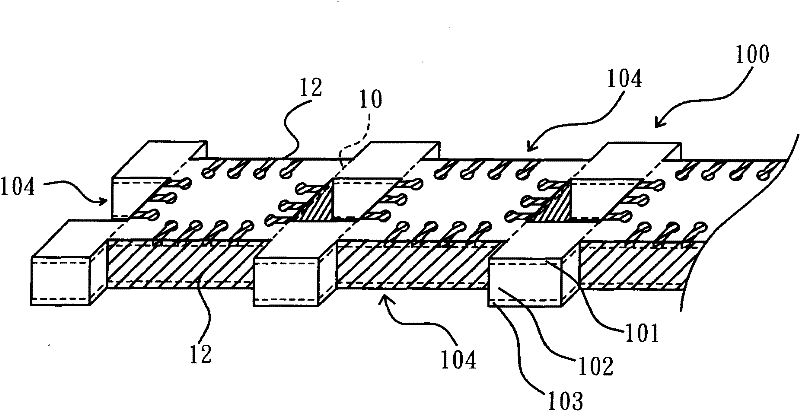

[0028] Please refer to Figure 1A As shown, the first step of the met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com