High-purity nitrogen equipment

A high-purity nitrogen and equipment technology, applied in lighting and heating equipment, liquefaction, solidification and other directions, can solve the problem of high energy consumption, achieve the effect of low energy consumption, simple process configuration and material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The principle of the invention is to use the difference in the boiling points of oxygen and nitrogen in the air to produce high-purity nitrogen by means of low-temperature rectification.

[0026] Specific embodiments of the present invention will be described below with reference to the drawings.

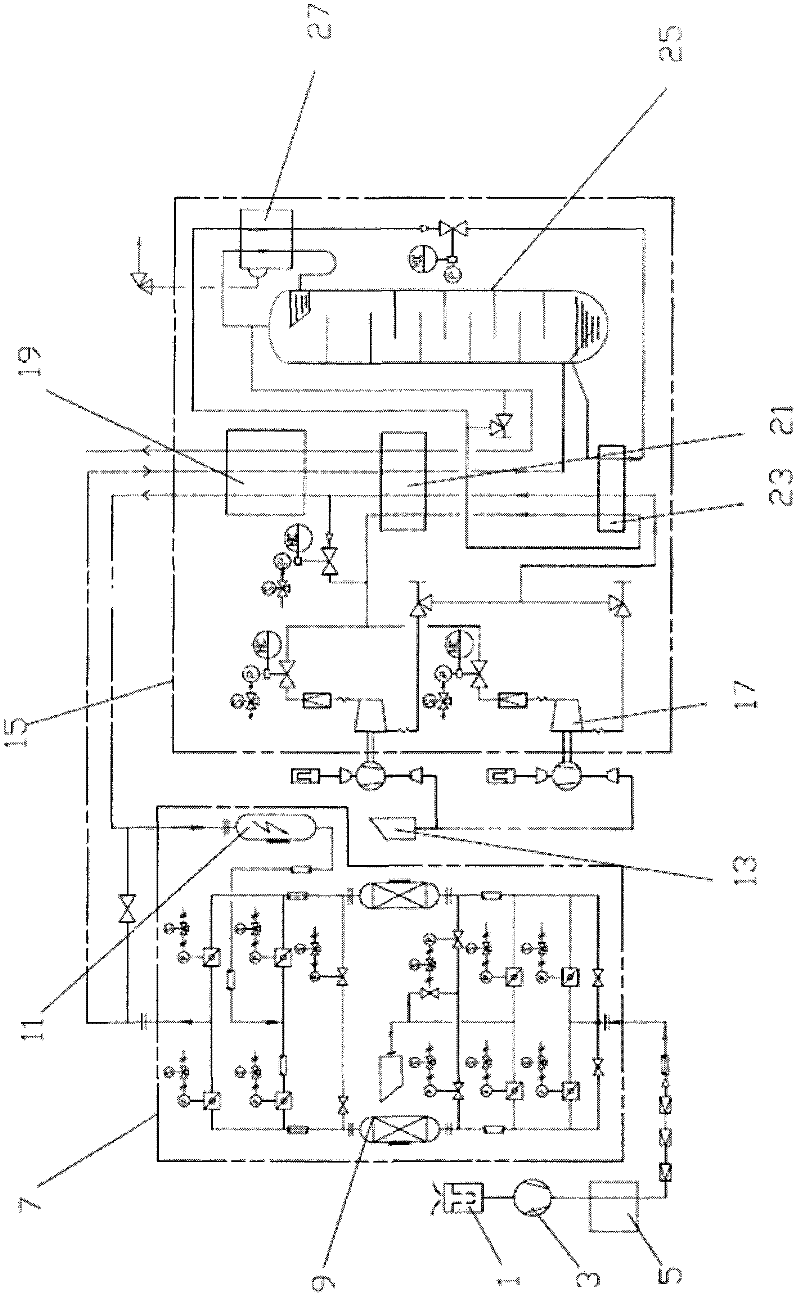

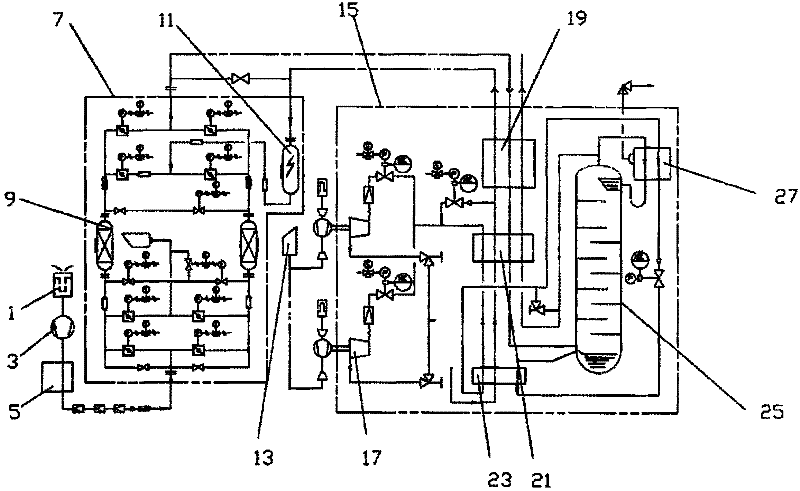

[0027] Such as figure 1 , the high-purity nitrogen equipment of the present invention mainly includes a pretreatment system, a purification system 7 and a fractionation tower 15 interconnected by pipelines.

[0028] The pretreatment system includes a filter 1, an air compressor 3, and a cold dryer 5 interconnected by pipelines. The cold dryer 5 is equipped with a high-efficiency three-stage oil removal filter to ensure that the oil content of the air outlet is less than 0.003PPm, which reduces the load on the purification system 7 and ensures the safe and efficient operation of the purification system 7. The application of the cold dryer 5 also makes the normal pressure dew...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com