Method for preparing nano pore composite humidity adjusting material

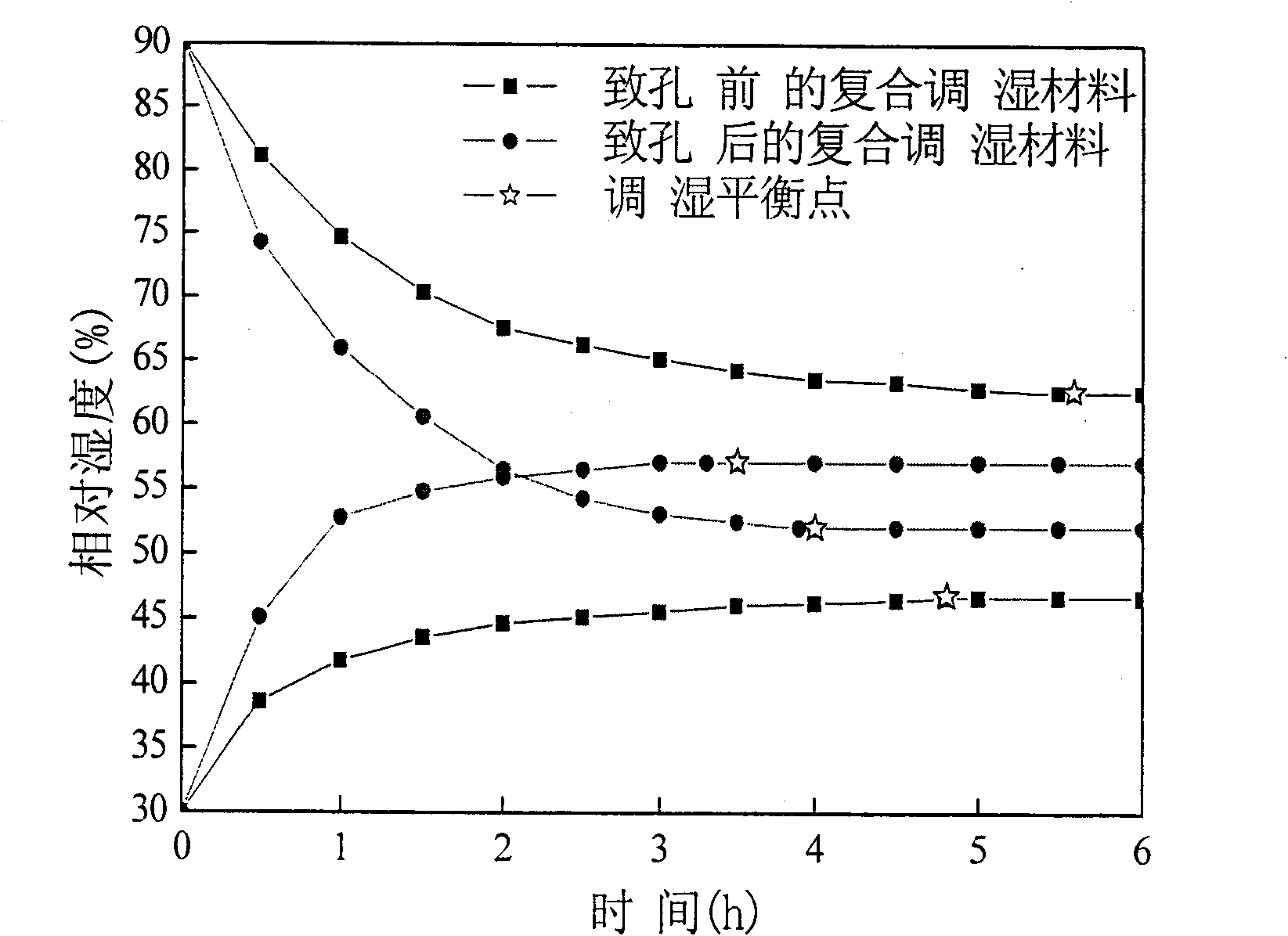

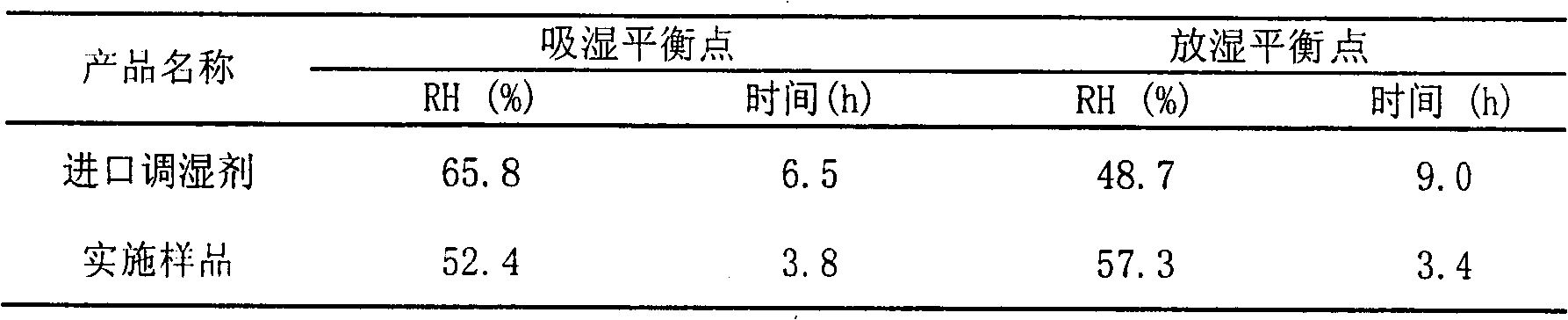

A humidity-regulating material and nanopore technology, applied in chemical instruments and methods, and other chemical processes, can solve the problems of moisture absorption and desorption performance limitations, difficult release of water molecules, and insufficient moisture capacity, etc. Fast response to dehumidification, large moisture absorption and desorption capacity, and convenient reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A method for preparing a nanoporous composite humidity-regulating material, characterized in that the following steps are adopted:

[0021] A) Take 0.5 parts of organic polymer materials, 2 parts of natural polymer materials, and 10 parts of inorganic porous substances with a particle size of 120 mesh according to the number of parts by mass, add them to a reaction kettle with 50 parts of water, and stir at a temperature of 80 ° C. Reaction for 20 minutes; the organic polymer material is one or more of polyacrylamide, acrylamide, and sodium polyacrylate; the natural polymer material is one of cellulose, carboxymethyl cellulose, and ethyl cellulose; inorganic porous The substance is one of sepiolite, diatomite, montmorillonite, and zeolite. When polyacrylamide is used as the organic polymer material, 0.2 parts of modifier must be added at the same time. The modifier is calcium chloride, magnesium chloride, and magnesium nitrate. , one of calcium nitrate.

[0022] B) Add...

Embodiment 2

[0026] A method for preparing a nanoporous composite humidity-regulating material, characterized in that the following steps are adopted:

[0027] A) According to the number of parts by mass, take 15 parts of organic polymer materials, 2 parts of natural polymer materials, and 10 parts of inorganic porous substances with a particle size of 110 mesh, add them to a reaction kettle with 50 parts of water, and stir at a temperature of 70 ° C. Reaction for 20 minutes; the organic polymer material is one or more of polyacrylamide, acrylamide, and sodium polyacrylate; the natural polymer material is one of cellulose, carboxymethyl cellulose, and ethyl cellulose; inorganic porous The substance is one of sepiolite, diatomite, montmorillonite, and zeolite. When polyacrylamide is used as the organic polymer material, 0.5 parts of modifier must be added at the same time. The modifier is calcium chloride, magnesium chloride, and magnesium nitrate. , one of calcium nitrate.

[0028] B) Add...

Embodiment 3

[0032] A method for preparing a nanoporous composite humidity-regulating material, characterized in that the following steps are adopted:

[0033] A) According to the number of parts by mass, take 30 parts of organic polymer materials, 2 parts of natural polymer materials, and 10 parts of inorganic porous substances with a particle size of 100 mesh, add them to a reaction kettle with 50 parts of water, and stir at a temperature of 60 ° C. Reaction for 20 minutes; the organic polymer material is one or more of polyacrylamide, acrylamide, and sodium polyacrylate; the natural polymer material is one of cellulose, carboxymethyl cellulose, and ethyl cellulose; inorganic porous The substance is one of sepiolite, diatomite, montmorillonite, and zeolite. When polyacrylamide is used as the organic polymer material, 0.8 parts of modifier must be added at the same time. The modifier is calcium chloride, magnesium chloride, and magnesium nitrate. , one of calcium nitrate.

[0034] B) Add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com