Method for preparing high-efficiency composite humidity controlling agent

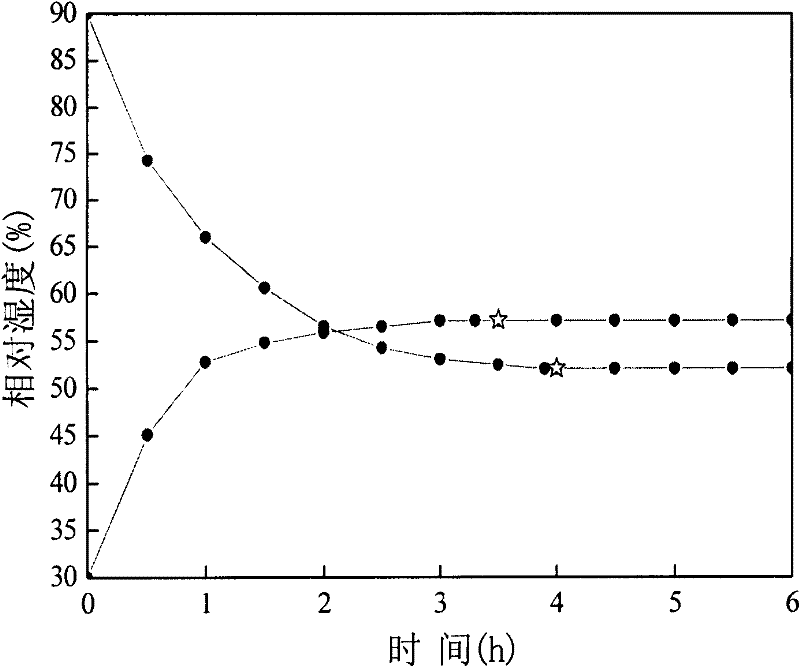

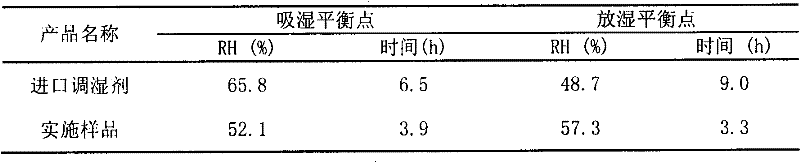

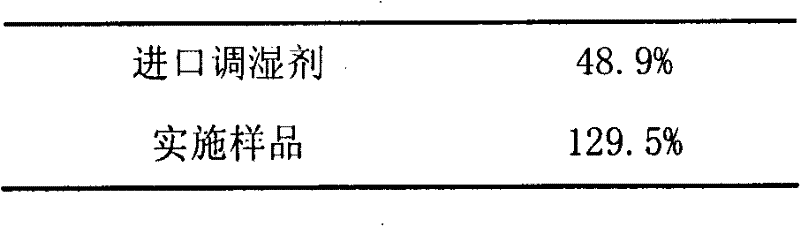

A humidity-conditioning agent and high-efficiency technology, which is applied in the field of preparation of high-efficiency composite humidity-conditioning agents, can solve the problems of moisture absorption and desorption performance limitation, hysteresis hysteresis, and insufficient moisture capacity, etc., and achieve fast response speed of moisture absorption and desorption , large moisture absorption and desorption capacity, and convenient repeated use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A preparation method of high-efficiency composite humidity-conditioning agent is characterized in that the following steps are adopted:

[0020] A) Take 10 parts of sepiolite with a particle size of 100 mesh and 3 parts of hydrochloric acid in parts by mass, add them to 100 parts of water, stir at 50°C for 3 hours, filter, wash with water three times, and dry to obtain activated sea foam stone;

[0021] B) Take 15 parts of acrylamide in parts by mass, 2 parts of sodium polyacrylate, 2 parts of carboxymethyl cellulose, 4 parts of activated sepiolite, 0.1 part of potassium persulfate, 0.03 part of N, N'-methylene Base bisacrylamide and 0.4 parts of aluminum chloride were respectively added to a reactor filled with 50 parts of water, and stirred and reacted for half an hour at a temperature of 60°C;

[0022] C) Add 1.2 parts of sodium bicarbonate into the above-mentioned reactor according to the mass parts of step B), and stir and react for 3 to 5 hours to obtain a synthe...

Embodiment 2

[0025] A preparation method of high-efficiency composite humidity-conditioning agent is characterized in that the following steps are adopted:

[0026] A) Take 10 parts of sepiolite with a particle size of 100 mesh and 3 parts of hydrochloric acid in parts by mass, add them to 100 parts of water, stir at 50°C for 3 hours, filter, wash with water three times, and dry to obtain activated sea foam stone;

[0027] B) Take 10 parts of acrylamide in parts by mass, 2 parts of sodium polyacrylate, 2 parts of carboxymethyl cellulose, 4 parts of activated sepiolite, 0.1 part of potassium persulfate, 0.03 part of N, N'-methylene Base bisacrylamide and 0.4 parts of aluminum chloride were respectively added to a reactor filled with 50 parts of water, and stirred and reacted for half an hour at a temperature of 70°C;

[0028] C) Add 1.2 parts of sodium bicarbonate into the above-mentioned reactor according to the mass parts of step B), and stir and react for 3 to 5 hours to obtain a synthe...

Embodiment 3

[0031] A preparation method of high-efficiency composite humidity-conditioning agent is characterized in that the following steps are adopted:

[0032] A) Take 10 parts of sepiolite with a particle size of 100 mesh and 3 parts of hydrochloric acid in parts by mass, add them to 100 parts of water, stir at 50°C for 3 hours, filter, wash with water three times, and dry to obtain activated sea foam stone;

[0033] B) Take 5 parts of acrylamide in parts by mass, 2 parts of sodium polyacrylate, 2 parts of carboxymethyl cellulose, 4 parts of activated sepiolite, 0.1 part of potassium persulfate, 0.03 part of N, N'-methylene Base bisacrylamide and 0.4 parts of aluminum chloride were respectively added to a reactor filled with 50 parts of water, and stirred and reacted for half an hour at a temperature of 80°C;

[0034] C) Add 1.2 parts of sodium bicarbonate into the above-mentioned reactor according to the mass parts of step B), and stir and react for 3 to 5 hours to obtain a synthet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com