Laser synthesis method of CaTiO3-CaTiSiO5

A technology of laser synthesis and gas laser, which is applied in the field of preparation of high-frequency dielectric ceramic materials, can solve the problems of complex process, low purity, and high energy consumption, and achieve the effect of simple process, high purity, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] CaCO used in the following examples 3 、TiO 2 and SiO 2 The powders were all 99.0% pure.

[0033] CaCO 3 、TiO 2 and SiO 2 The powders were mixed in a molar ratio of 1:1:0.5, the total amount was 10 g, ground in an agate mortar for 8 hours, dried at 120°C for 2 hours, and then ground in an agate mortar for 8 hours. Press the fully mixed powder into a compact under a pressure of 8Mpa and hold the pressure for 60s. The green body has a diameter of 14mm and a thickness of 3mm.

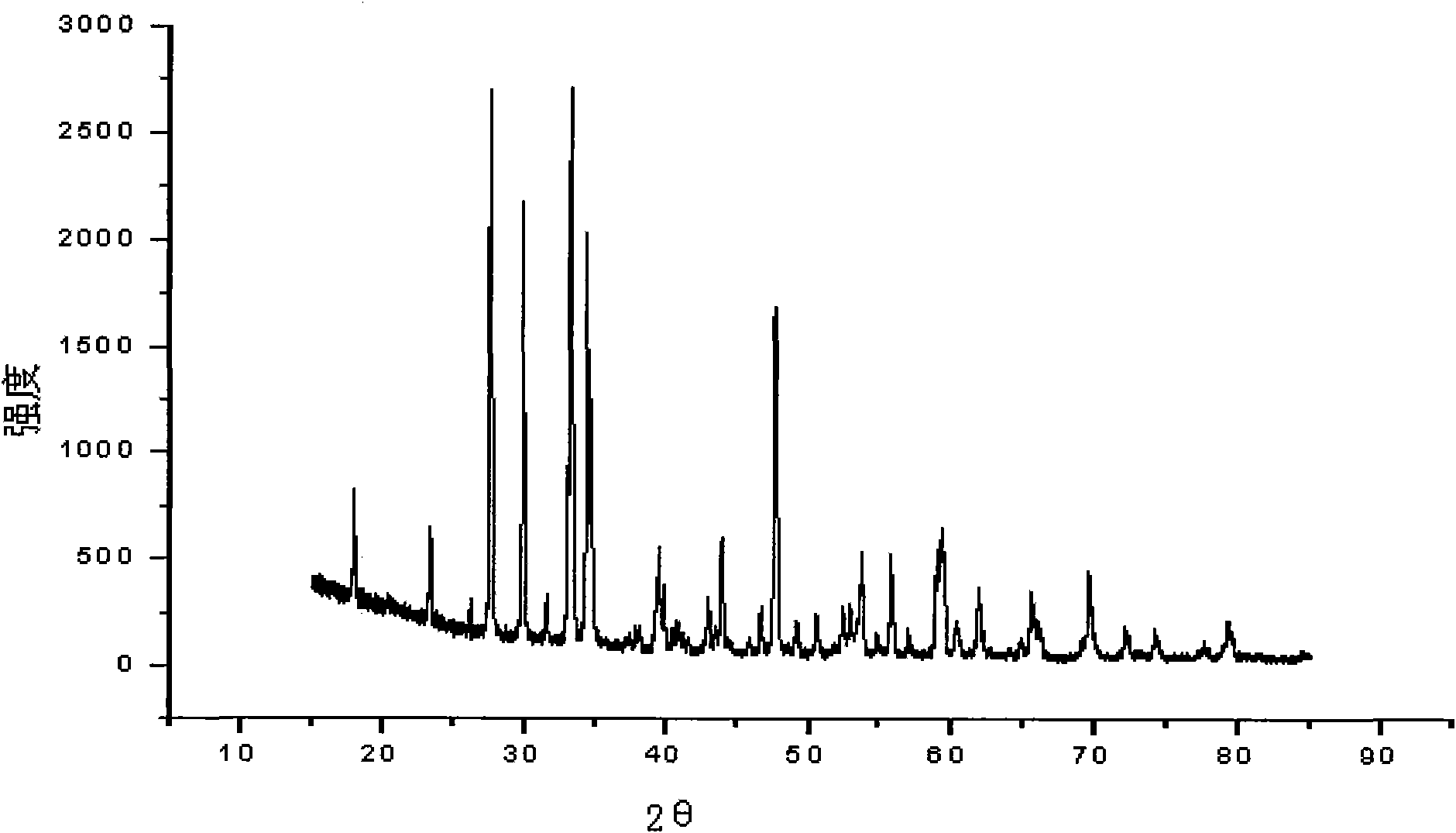

[0034] Place the green body on the sample stage, use CO with a laser power of 800W and a defocus of 90mm 2 The laser beam directly irradiates the green body, and the irradiation time is 190s. The prepared sample is tested in powder form by X-ray diffraction (XRD), density and dielectric constant, and the test results are shown infigure 1 and Table 1.

[0035] figure 1 The XRD results showed that high-purity CaTiO was synthesized 3 -CaTiSiO 5 Mutually.

Embodiment 2

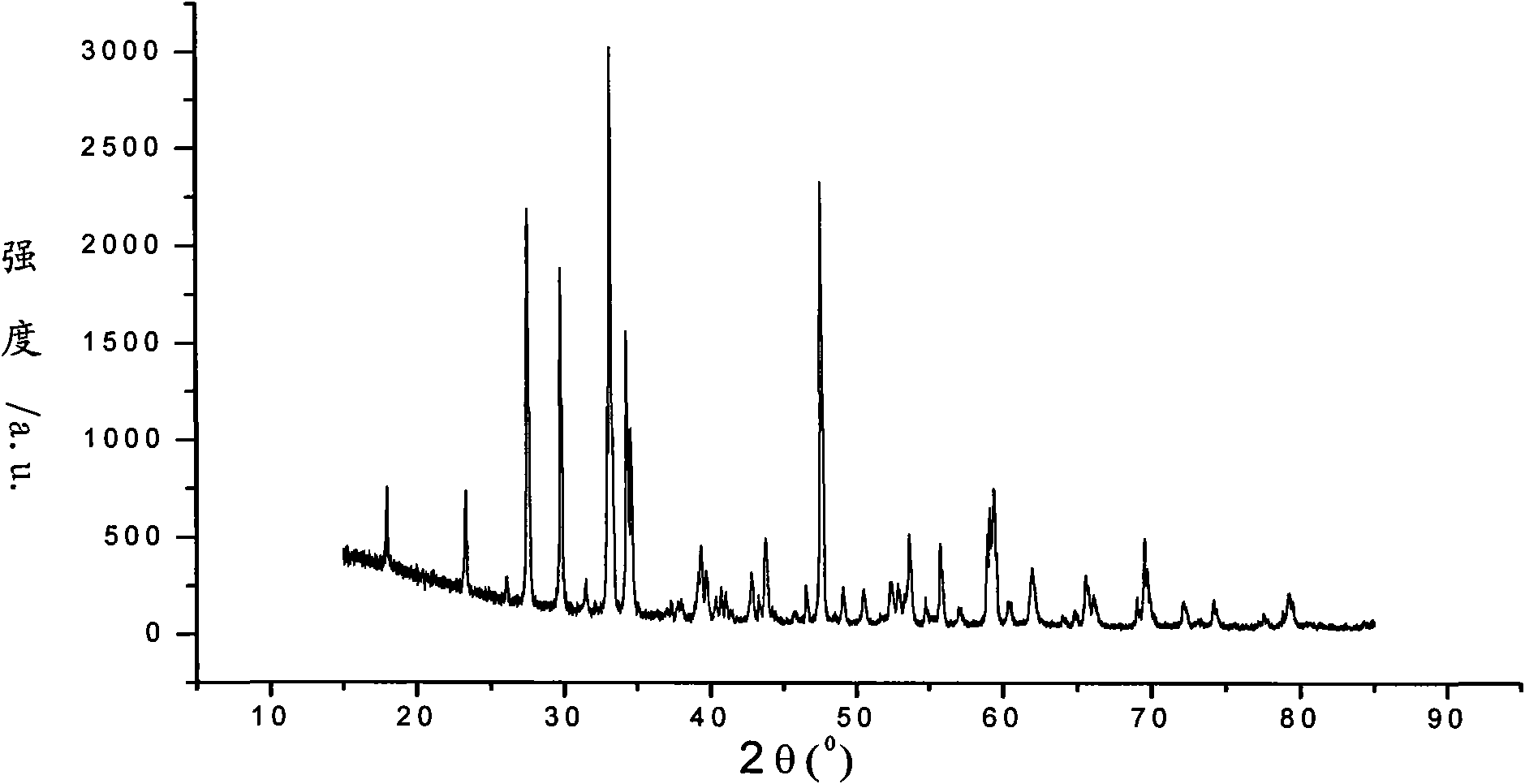

[0037] The difference from Example 1 is that the laser power is 1000W, and the irradiation time is 170s. The prepared samples are processed, and the prepared samples are tested in powder form by X-ray diffraction (XRD), scanning electron microscope (SEM), density and dielectric constant. The test results are shown in figure 2 and Table 1.

Embodiment 3

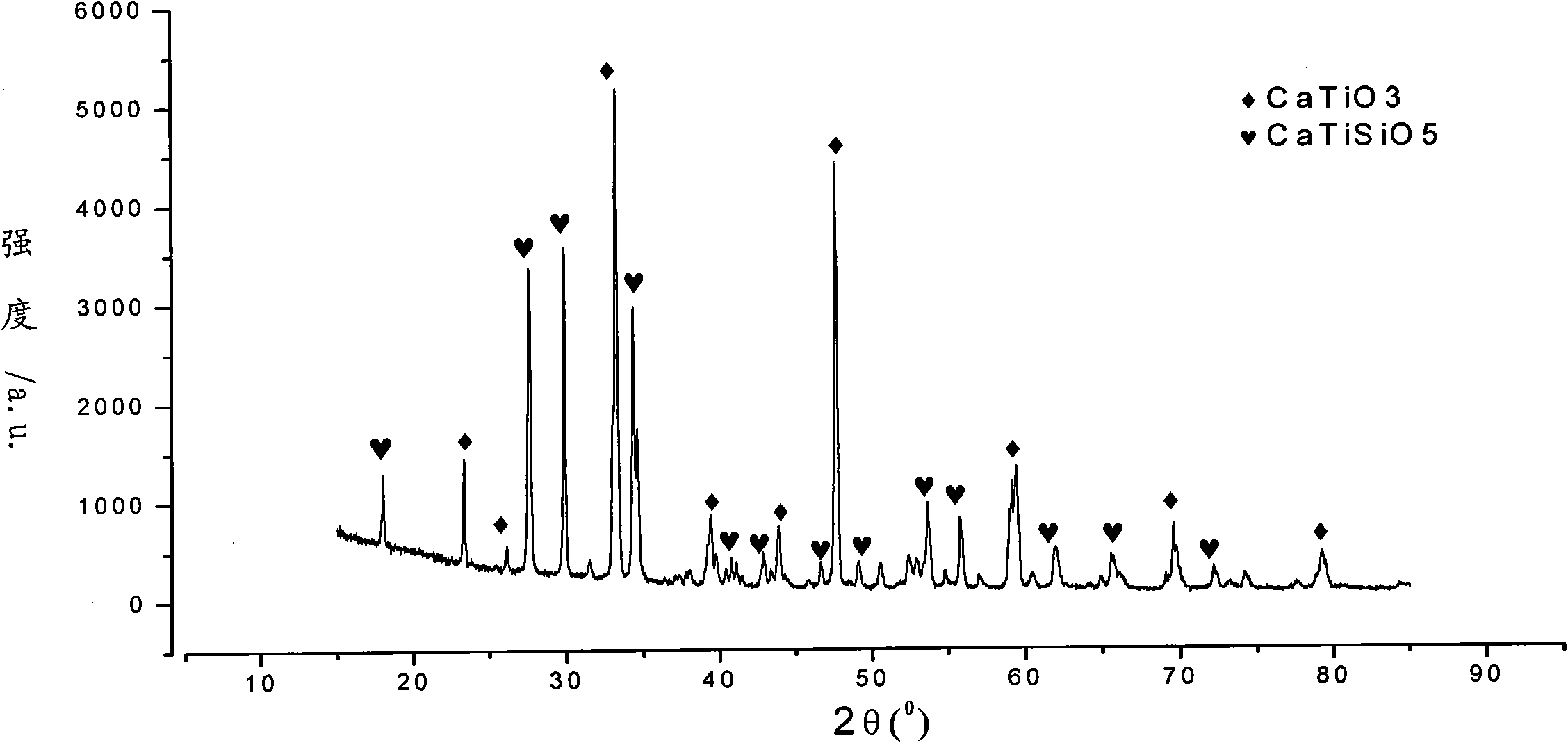

[0039] The difference from Example 1 is that the laser power is 1200W, and the irradiation time is 140s. The prepared samples were processed, and the prepared samples were subjected to X-ray diffraction (XRD), scanning electron microscope (SEM), density and dielectric constant tests in bulk and powder form respectively. The test results are shown in image 3 , 4 , 6, 7 and Table 1.

[0040] in image 3 It is the XRD figure of powder, shows that the present invention can make high-purity CaTiO 3 -CaTiSiO 5 high frequency ceramics, Figure 4 It is a block XRD pattern, which shows that laser sintering has strong orientation growth. Image 6 It is the SEM photo of the section enlarged 300 times, showing that the prepared CaTiO 3 -CaTiSiO 5 The microstructure is relatively dense and there are no pores; Figure 7 It is a SEM photo of the cross-section magnified 500 times. It can be clearly seen that the crystal grains are large, growing in a dendritic structure, and have the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com