All paper tray and manufacturing method thereof

A production method and tray technology, applied to cardboard items, rigid containers, containers, etc., can solve the problems of resource scarcity, increased packaging costs, and troubled export business, and achieve the effects of saving forest resources, reducing direct costs, and increasing fiscal revenue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

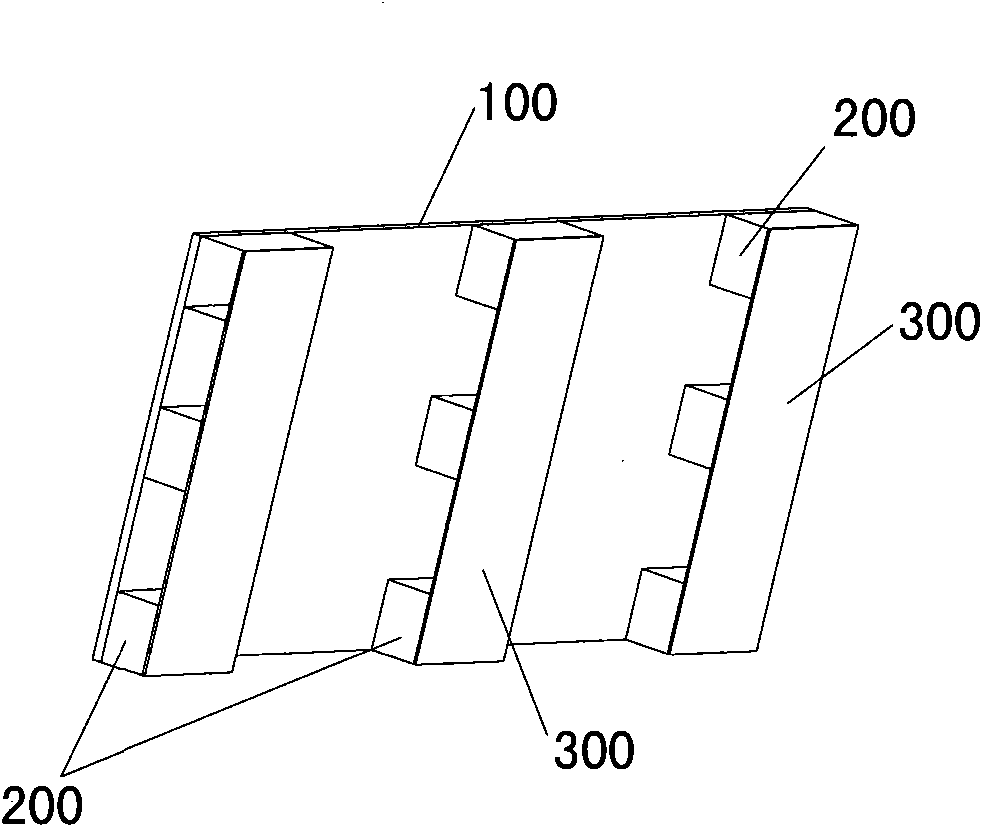

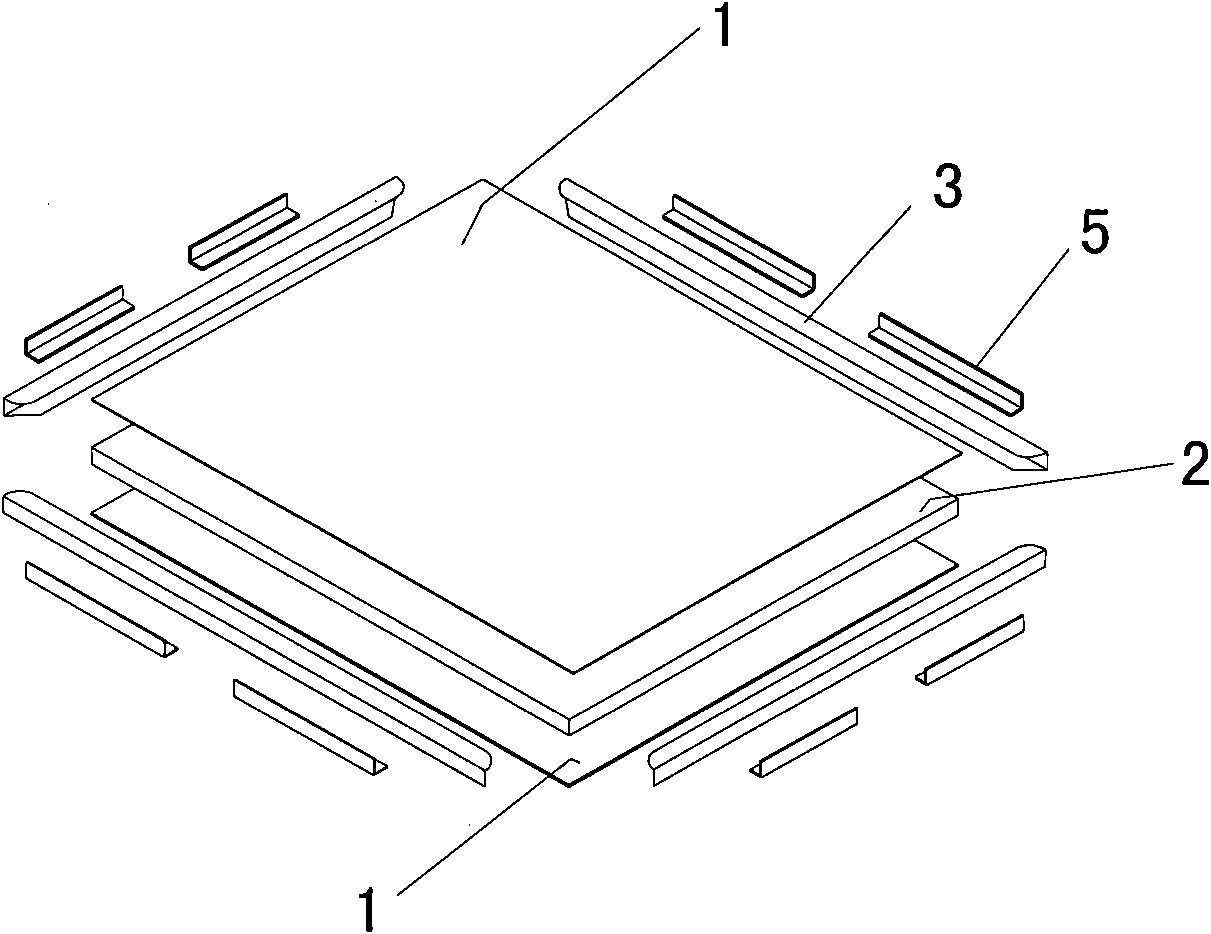

[0035] Such as figure 1 and figure 2 As shown, a full paper pallet includes a top deck 100 , a pallet bottom pier 200 supporting the top deck 100 and a pallet bottom belt 300 connecting the pallet bottom pier 200 . There are multiple pallet bottom piers 200, and a plurality of pallet bottom piers 200 are arranged in a row on the bottom surface of the top plank 100, and the lower surface of the pallet bottom piers 200 in the same row is provided with a pallet bottom belt 300 connecting them, Three rows of pallet piers 200 are shown, with three pallet piers 200 in each row. The pallet bottom belt 300 adopts such as Figure 5 Paper card board 1 shown.

[0036] image 3 It is a schematic diagram of the exploded structure of the top plank of the all-paper pallet of the present inventi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com