Low alloyed steel powder

一种钢粉、预合金化的技术,应用在粉末锻造部件领域,能够解决降低压缩屈服强度和硬度等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] Preparation of Iron-based Alloy Steel Powder

[0027] Steel powder is produced by water atomization of a steel melt containing specified amounts of alloying elements. The atomized powder was further subjected to reduction annealing as described in US Patent 6,027,544, which is hereby incorporated by reference. The particle size of the steel powder can be any size as long as it is compatible with pressing and sintering or powder forging methods. Examples of suitable particle sizes are available from AB, Sweden's known powder ABC100.30 has a particle size of about 10% by weight above 150 microns and about 20% by weight below 45 microns.

[0028] Content of steel powder

[0029] Chromium is used to strengthen the matrix by solution hardening. Chromium also improves the hardenability, oxidation resistance and wear resistance of the sintered body. However, a chromium content higher than 1.5% by weight reduces the compressibility of the steel powder and results in le...

Embodiment

[0055] Manufacture of various prealloyed iron-based steel powders by water atomization of steel melts. The resulting green powder was further annealed in a reducing atmosphere followed by gentle grinding to disintegrate the sintered powder mass. The powder particle size is below 150 microns. Table 1 shows the chemical composition of the different powders.

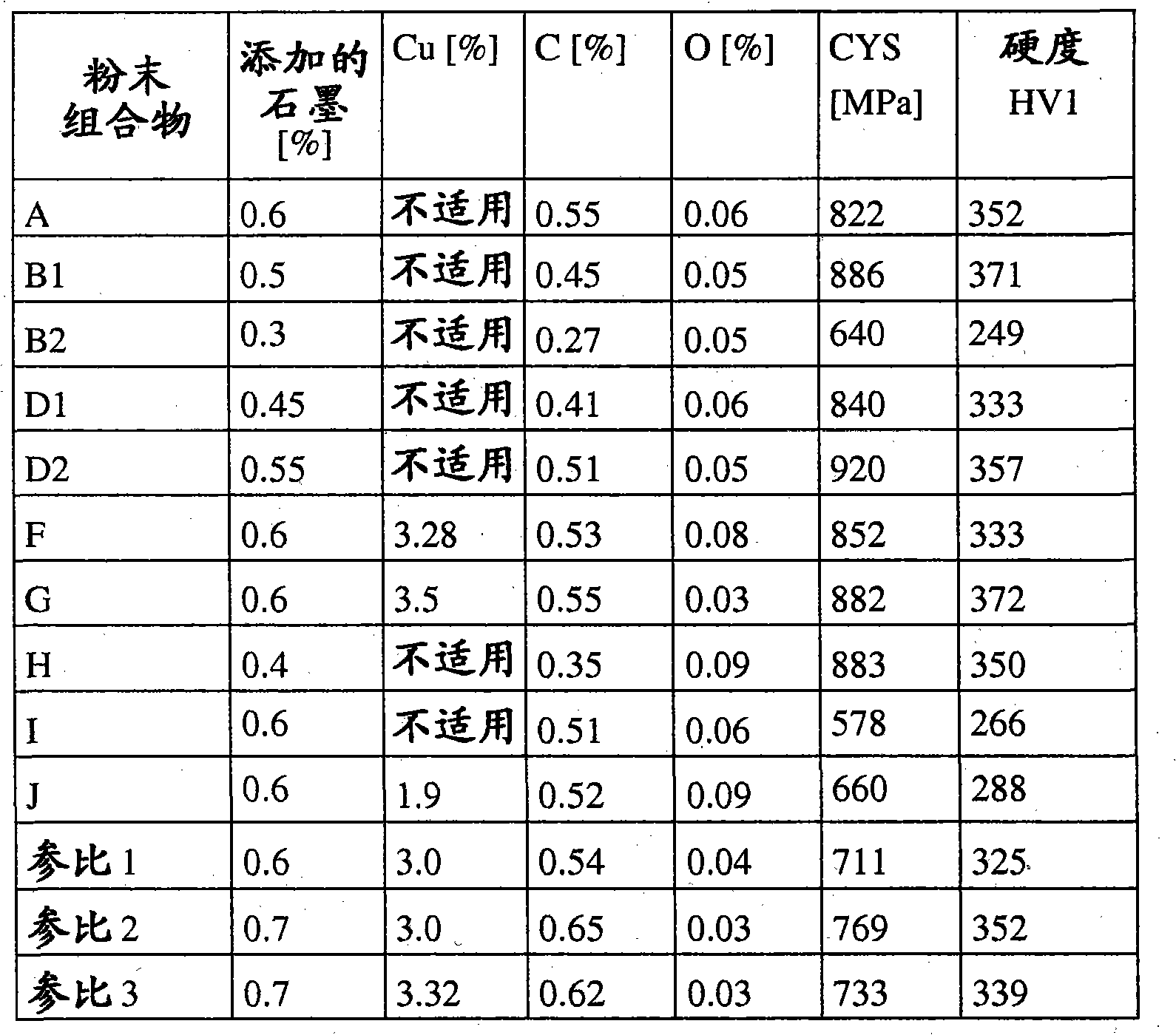

[0056] Table 1

[0057]

[0058] Table 1 shows the chemical compositions of Steel Powders A to J and References 1 to 3.

[0059] The resulting steel powders A to J were mixed with graphite 1651 from Asbury, USA according to the amount specified in Table 2 and 0.8% available from AB, Amide Wax PM Blend, Sweden. To some of this composition was added copper powder Cu-165 from A Cu Powder, USA according to the amounts specified in Table 2.

[0060] As a reference composition, based on the available AB, Iron powder AHC100.29 from Sweden and two iron-copper carbon compositions ref 1 and ref 2 were prepared according to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com