Mercury-free full-protection paste type zinc-manganese battery

A zinc-manganese battery and anti-paste technology, which is applied in dry batteries, battery pack components, circuits, etc., can solve problems such as implementation difficulties and unsatisfactory battery electrical performance, and achieve enhanced corrosion inhibition effect, good corrosion inhibition effect, and cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

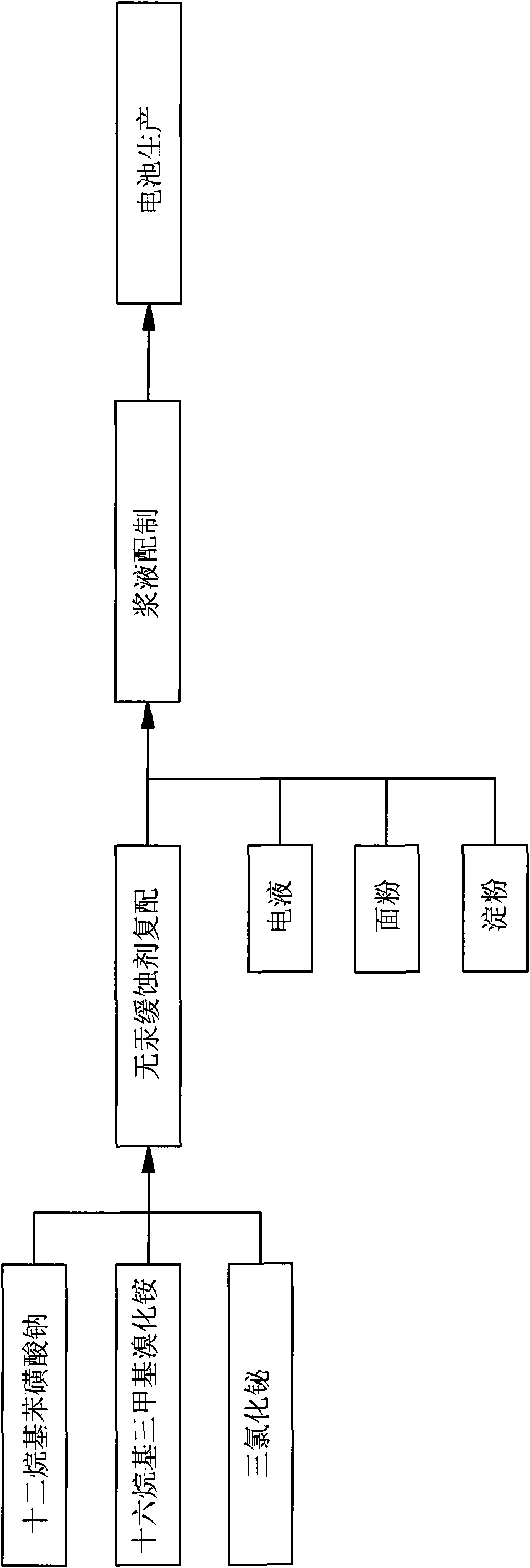

Method used

Image

Examples

Embodiment 1

[0022] R20S mercury-free full anti-paste zinc-manganese battery electrolyte formula contains ZnCl per liter of electrolyte 2 15.5%, NH 4 Cl 20%, the balance is water; the ratio of flour and starch in each liter of electro-liquid is 3:7, and the slurry contains 8% flour, 18.5% starch, 2% polyacrylamide, 25% ammonium chloride, Zinc 14%, the balance is water. Mercury-free corrosion inhibitors are added to the slurry: cetyltrimethylammonium bromide (CTAB) 0.03%, sodium dodecylbenzenesulfonate (SDBS) 0.04%, bismuth trichloride (BiCl 3 )0.03%. Through stirring, filtering, and controlling the viscosity, make a mercury-free slurry, input it into the production line, inject it into the zinc cylinder, and form an isolation layer between the zinc cylinder and the battery core, and make the slurry mature and solidify through the gelatinization process without mercury corrosion inhibition. The agent is evenly distributed in it to play a role in inhibiting the corrosion of zinc.

Embodiment 2

[0024] The electrolyte formula and the slurry formula are the same as in Example 1, except that the mercury-free corrosion inhibitor cetyltrimethylammonium bromide (CTAB) 0.025%, sodium dodecylbenzenesulfonate (SDBS) are added to the slurry 0.035%, bismuth trichloride (BiCl 3 )0.05%.

Embodiment 3

[0026] The electrolyte formula and the slurry formula are the same as in Example 1, except that the mercury-free corrosion inhibitor cetyltrimethylammonium bromide (CTAB) 0.025%, sodium dodecylbenzenesulfonate (SDBS) are added to the slurry 0.035%, bismuth trichloride (BiCl 3 )0.04%.

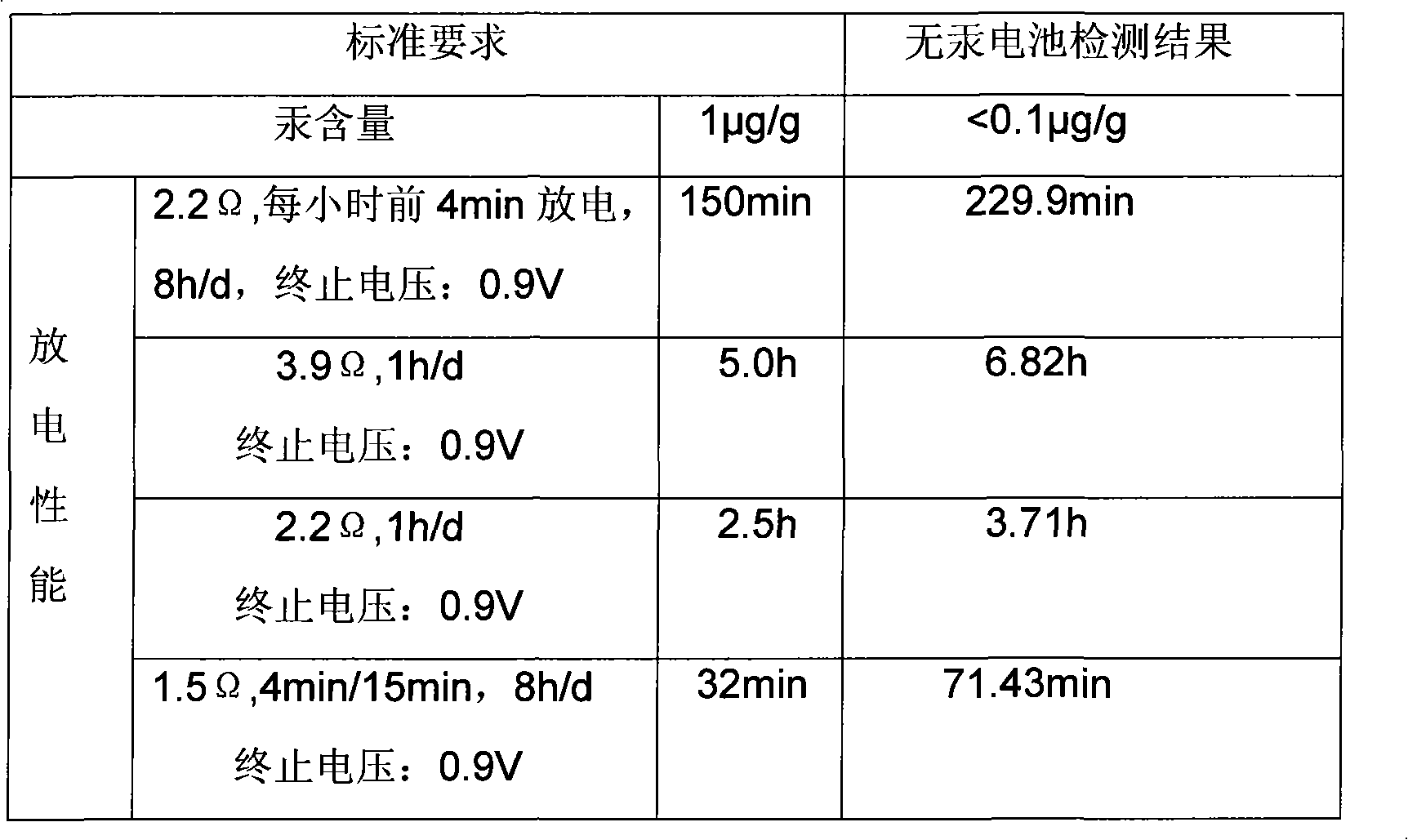

[0027] The battery production process of the above three embodiments is the same as the traditional full anti-paste zinc-manganese battery production process. The open-circuit voltage of the battery produced according to the corrosion inhibitor ratio of the three examples is 1.65V-1.725V, the short-circuit current: ≥6.0A, and the electrical properties all meet the requirements of the GB8897.2-2005 standard.

[0028] Through the battery test, observe the corrosion situation of the inner surface of the new battery, the zinc cylinder stored for half a year and one year, it is shown that the three corrosion inhibitors of the present invention have synergistic corrosion inhibition effect.

[0029] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com