Clean room with non-thermal plasma air disinfection purifier

A non-thermal plasma and air disinfection technology, applied in the field of clean room, can solve the problems of short working life, impracticality, high voltage and high power switching devices, etc., and achieve the effect of degrading formaldehyde and high killing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

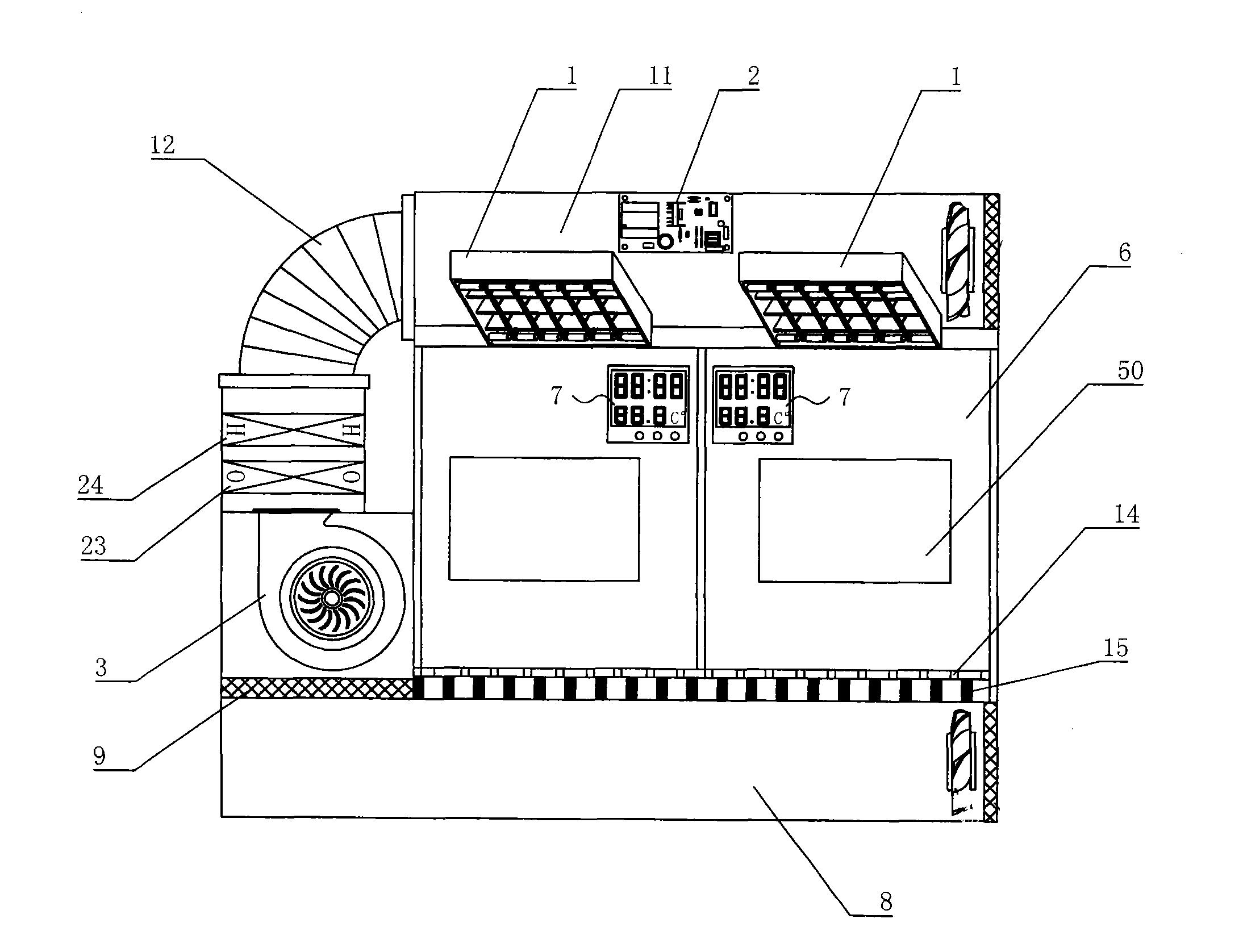

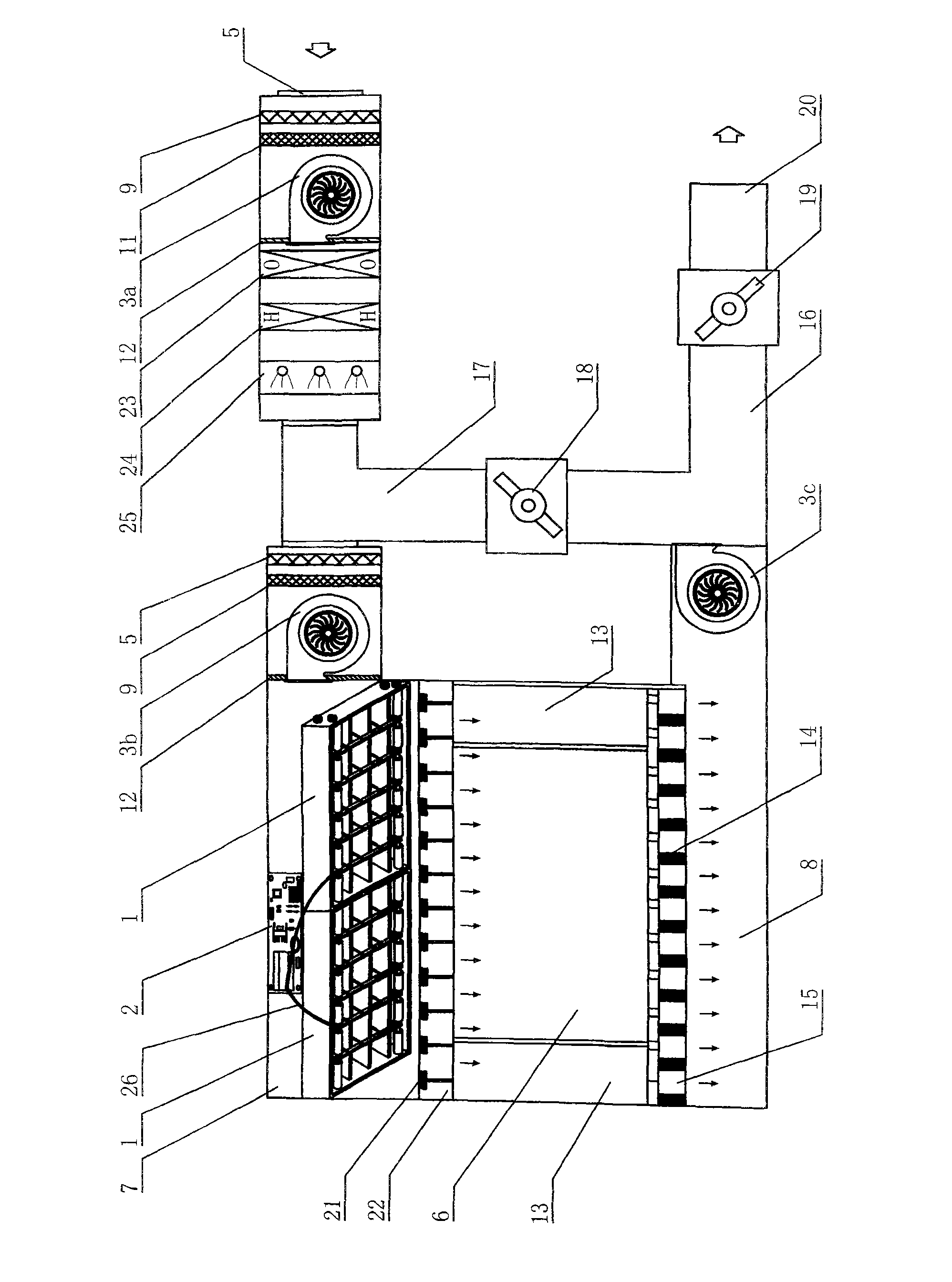

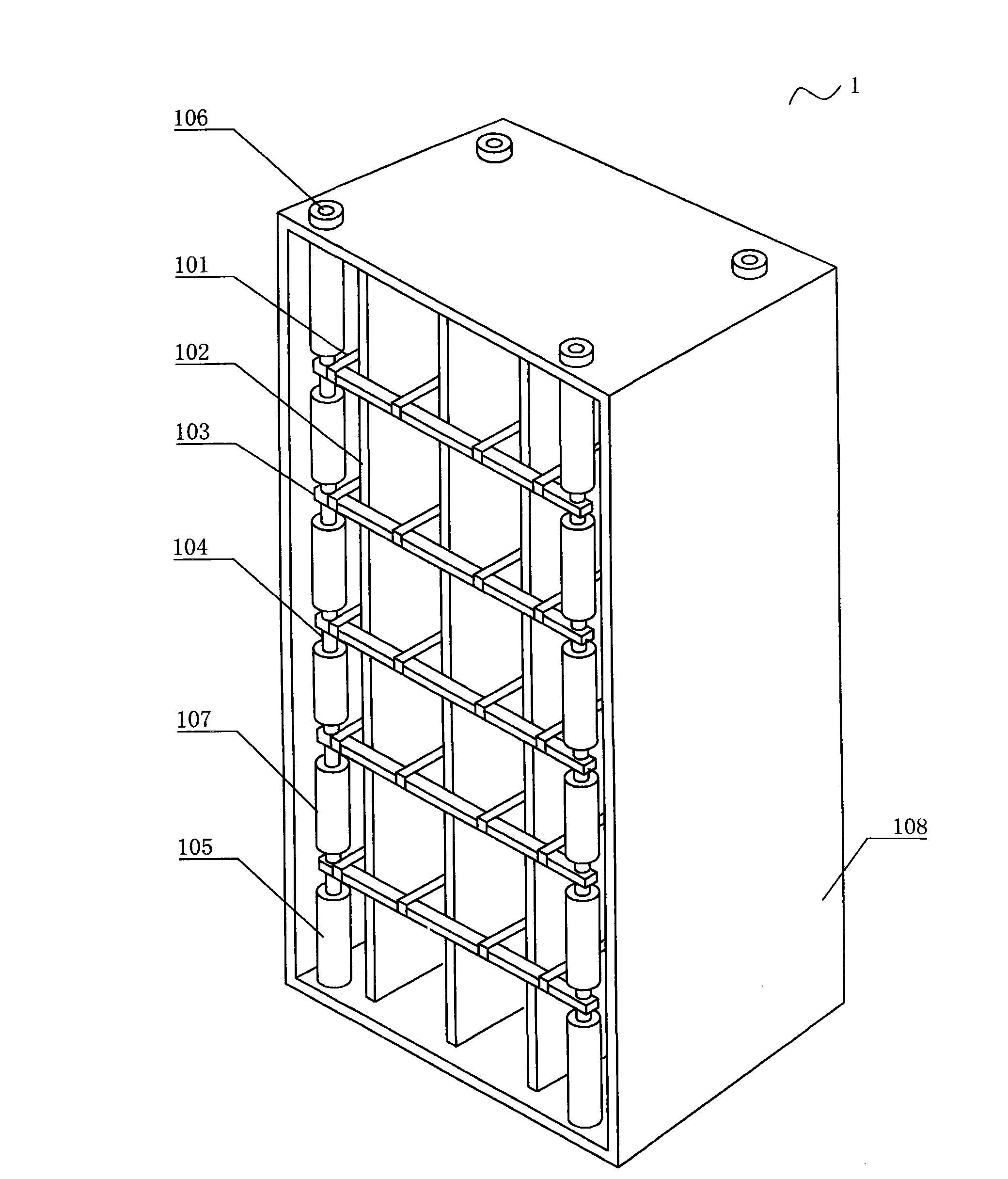

[0062] refer to figure 1 , a schematic diagram of the clean room structure equipped with a non-thermal plasma air disinfection purifier; image 3 It is the three-dimensional structure diagram of the plasma reactor of the present invention.

[0063] figure 1Among them, a clean room equipped with a non-thermal plasma air disinfection purifier, including air purification unit 1, reactor power supply 2, fan 3, clean room 6, controller 7, return air trench 8, air filter 9, static pressure Box 11, return air elbow 12, grid floor 14, air cleaning unit 1 and reactor power supply 2 are installed in the static pressure box 11 on the top of clean room 6 to form an airtight environment. A surface cooler 23 and a heater 24 are arranged between the fan 3 and the return air elbow 12 . The inner wall of the return air elbow 12 is provided with sound-absorbing materials, and the inner wall of the clean room 6 is also provided with conductive glass windows 50 . Controller 7 is contained on ...

Embodiment 2

[0076] figure 2 It is a structural schematic diagram of another embodiment of a clean room with a fresh air system. The clean room equipped with a non-thermal plasma air disinfection purifier is equipped with a fresh air system 5 . The air cleaning unit 1 , the reactor power supply 2 and the controller 7 are installed in the static pressure box 11 . According to the volume and cleanliness requirements of the clean room, more than two air purification units 1 are installed, and the positive electrodes of all the plasma reactors are connected together by a high-voltage line 26 . Described plenum box 11 air inlets are provided with blower fan 3b, and the air inlet of blower fan 3b is provided with intermediate effect air filter 9 and primary effect filter 4; Primary effect filter 4 front ends are provided with fresh air system 5, The fresh air system 5 is sequentially provided with a primary filter 4, a medium-efficiency air filter 9, a fresh air fan 3a, a surface cooler 23, a...

Embodiment 3

[0080] Figure 5 It is a structural schematic diagram of the pulse transformer of the present invention; Figure 6 It is the pulse transformer circuit diagram of the present invention. A specially designed pulse transformer 205 for a clean room equipped with a non-thermal plasma air disinfection purifier is equipped with a multi-slot insulating bobbin 212, and the secondary coil 215 is wound on the multi-slot insulating bobbin 212 in three to five sections. The corresponding grooves are connected in series; the inner holes of the primary coil 214 and the secondary coil 215 are provided with a magnetic core 216 for electromagnetic coupling, and the magnetic circuit of the magnetic core 216 is provided with a magnetic air gap 218; The best design of the magnetic core 216 is an iron-based ultramicrocrystalline iron core, and a ferrite core can also be set. The positive output end of the secondary coil 215 is provided with the positive electrode of the plasma reactor of air puri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com