Lead-free anti-ferroelectric material and preparation method thereof

An anti-ferroelectric and embryonic technology, applied in the field of lead-free anti-ferroelectric materials and their preparation, can solve the problems of volatile, highly toxic, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

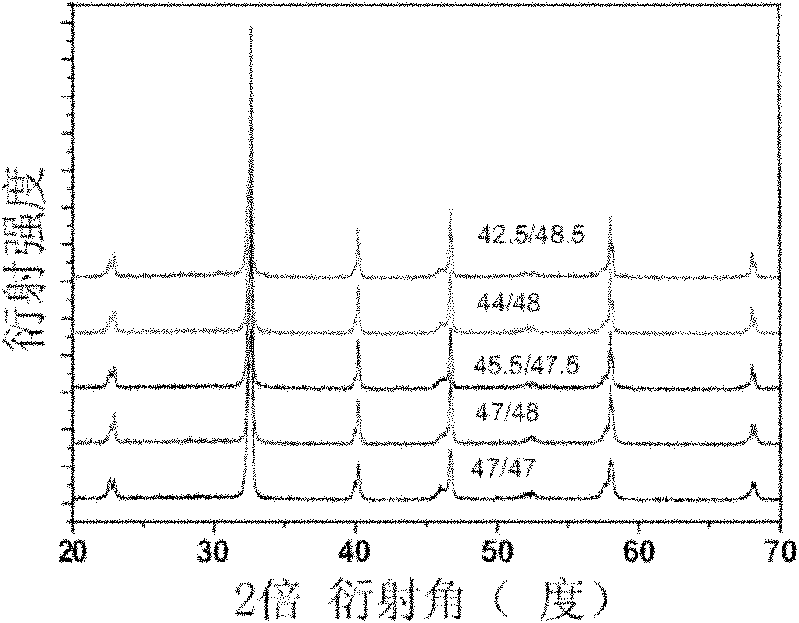

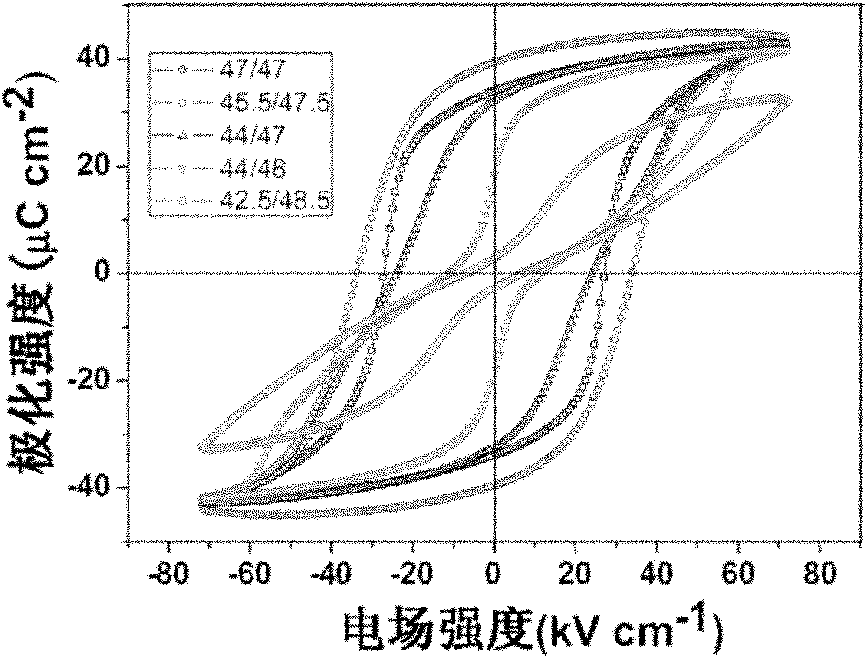

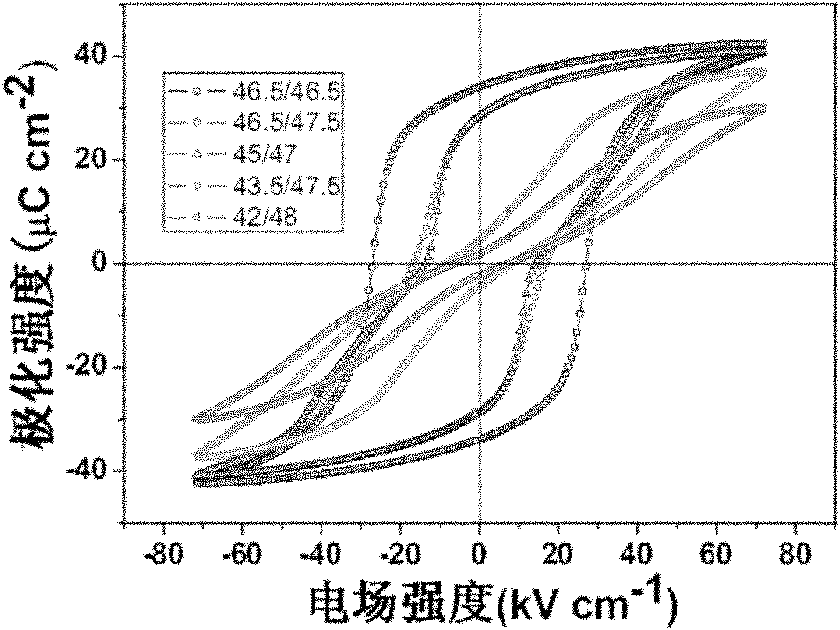

Image

Examples

Embodiment 1

[0022] Use analytical grade Na 2 CO 3 、 Bi 2 o 3 、BaCO 3 and TiO 2 Press N for raw material 44 B 48 T 94 -BT 6 The chemical formula is used for batching. The prepared raw materials use ethanol as the medium and use zirconia balls to mill in a ball mill jar for 12 hours. After drying and grinding, place them in an alumina crucible, calcinate at 800°C for 2 hours, cool to room temperature and reset Using ethanol as the medium in the ball milling jar, the zirconia balls were used for ball milling again in the ball milling jar for 2 hours. After drying, add binder PVA to granulate, and then use a mold to press through a press to obtain a cylindrical parison body with a diameter of 13 mm. The cylindrical green body is placed in a covered alumina crucible and placed in a furnace for sintering, and the heating rate can be controlled at 5°C / min. The sintering temperature is 1150°C, the holding time is 2 hours, and then the ceramic obtained by furnace cooling to room temperat...

Embodiment 2

[0024] Use analytical grade Na 2 CO 3 、 Bi 2 o 3 、BaCO 3 and nanoscale TiO 2 Press N for raw material39.5 B 43.5 T 85 -BT 15 The chemical formula is used for batching. The prepared raw materials use ethanol as the medium and use zirconia balls to mill in a ball mill jar for 24 hours. After drying and grinding, they are placed in an alumina crucible, calcined at 850°C for 3 hours, and reset after cooling to room temperature. Using ethanol as the medium in the ball milling jar, the zirconia balls were used for ball milling again for 12 hours in the ball milling jar. After drying, add binder PVA to granulate, and then use a mold to press through a press to obtain a cylindrical parison body with a diameter of 13 mm. The cylindrical green body is placed in a covered alumina crucible and placed in a furnace for sintering, and the heating rate can be controlled at 10°C / min. The sintering temperature is 1180°C, the holding time is 4 hours, and then the ceramics obtained by fu...

Embodiment 3

[0026] Use analytical grade Na 2 CO 3 、 Bi 2 o 3 、BaCO 3 and TiO 2 Press N for raw material 43.5 B 47.5 T 93 -BT 7 The chemical formula is used for batching. The prepared raw materials use ethanol as the medium and use zirconia balls to mill in a ball mill jar for 6 hours. After drying and grinding, place them in an alumina crucible, calcinate at 750°C for 2 hours, and reset after cooling to room temperature. Using ethanol as the medium in the ball milling jar, the zirconia balls were used for ball milling again in the ball milling jar for 6 hours. After drying, add binder PVA to granulate, and then use a mold to press through a press to obtain a cylindrical parison body with a diameter of 13 mm. The cylindrical green body is placed in a covered alumina crucible and placed in a furnace for sintering, and the heating rate can be controlled at 10°C / min. The sintering temperature is 1150°C, the holding time is 2 hours, and then the ceramic obtained by furnace cooling to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| piezoelectric charge coefficient | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com