Polyester film for release film for polarizer and layered product with improved polarizing property

A polarizing plate and release film technology, applied in the direction of polarizing elements, applications, coatings, etc., can solve the problems of difficult to find polarizing plate defects, missed inspections, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

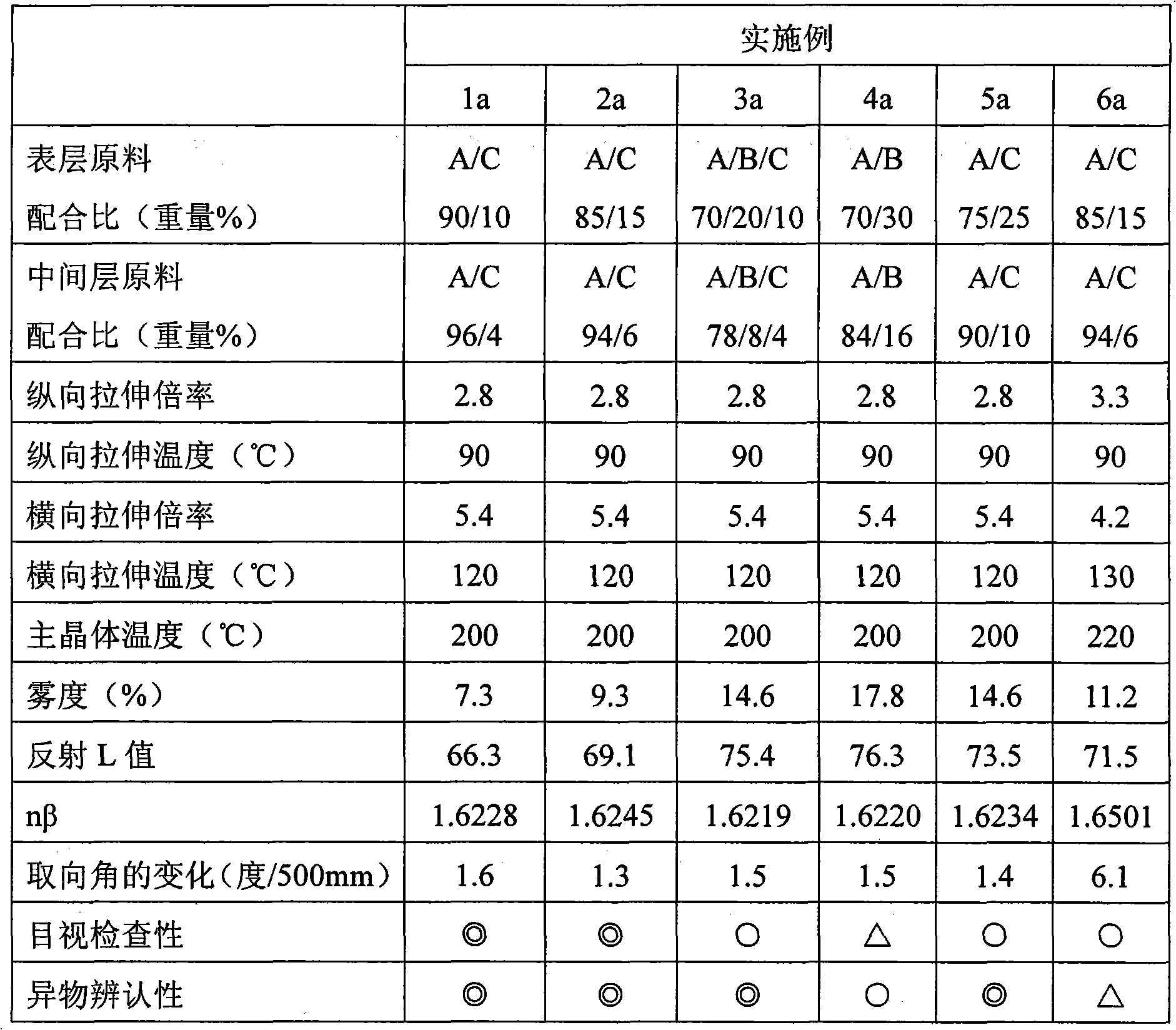

Embodiment 1a~6a

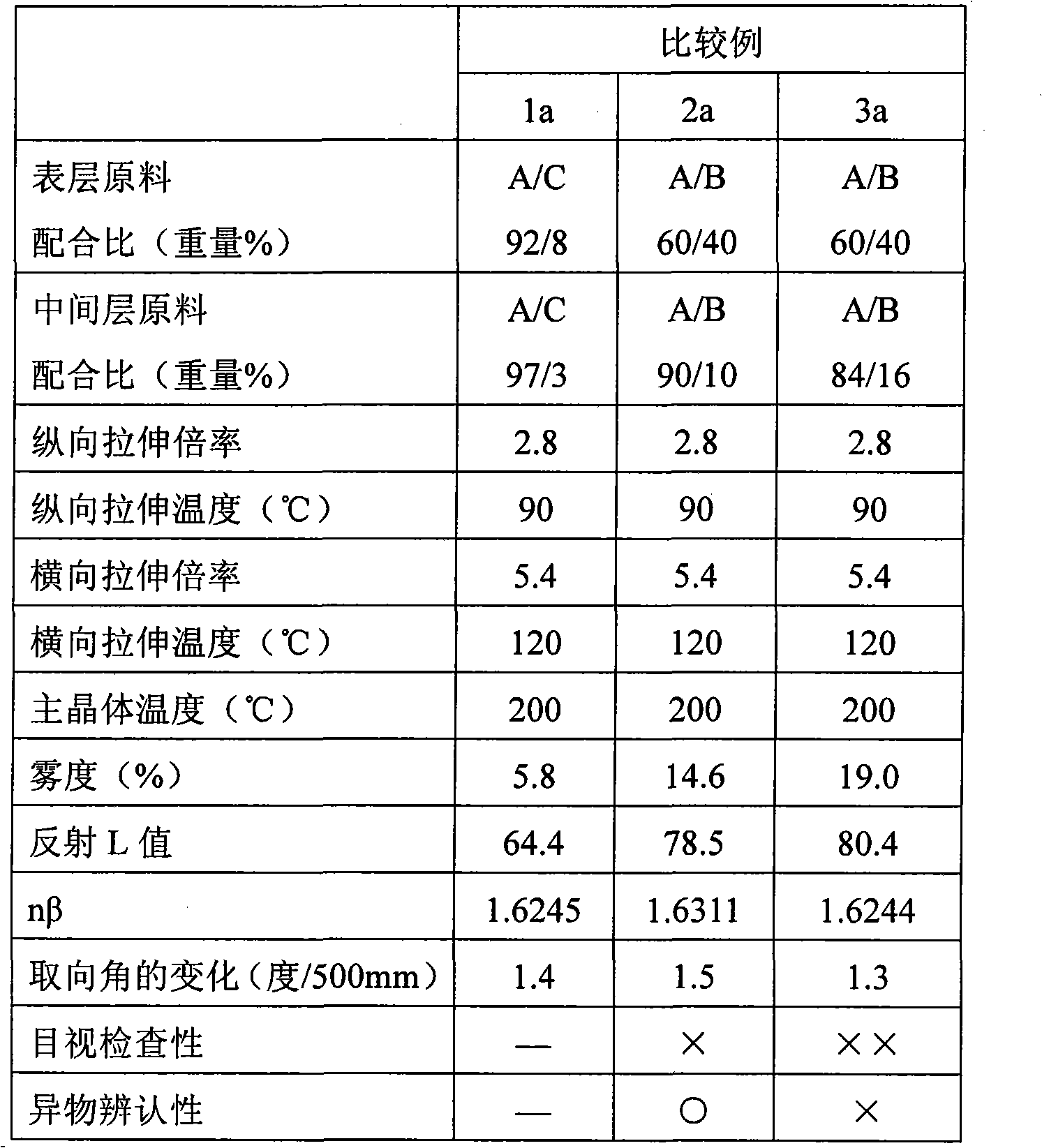

[0090] Embodiment 1a~6a and comparative example 1a~3a:

[0091]

[0092] Using 100 parts by weight of dimethyl terephthalate and 60 parts by weight of ethylene glycol as starting materials, add magnesium acetate tetrahydrate as a catalyst in the reactor, set the reaction initiation temperature to 150°C, and distill off Methanol was added, and the reaction temperature was gradually increased, reaching 230°C after 3 hours. After 4 hours, the transesterification reaction was substantially completed. After adding triethyl phosphate (ethyl acid phosphate) to this reaction mixture, it moved into the polycondensation tank, added 0.04 parts of antimony trioxide, and carried out polycondensation reaction for 4 hours. That is, the temperature was gradually raised from 230°C to 280°C. On the other hand, the pressure was gradually reduced from normal pressure to finally reach 0.3 mmHg. After the reaction started, the reaction was stopped at a time corresponding to an intrinsic viscos...

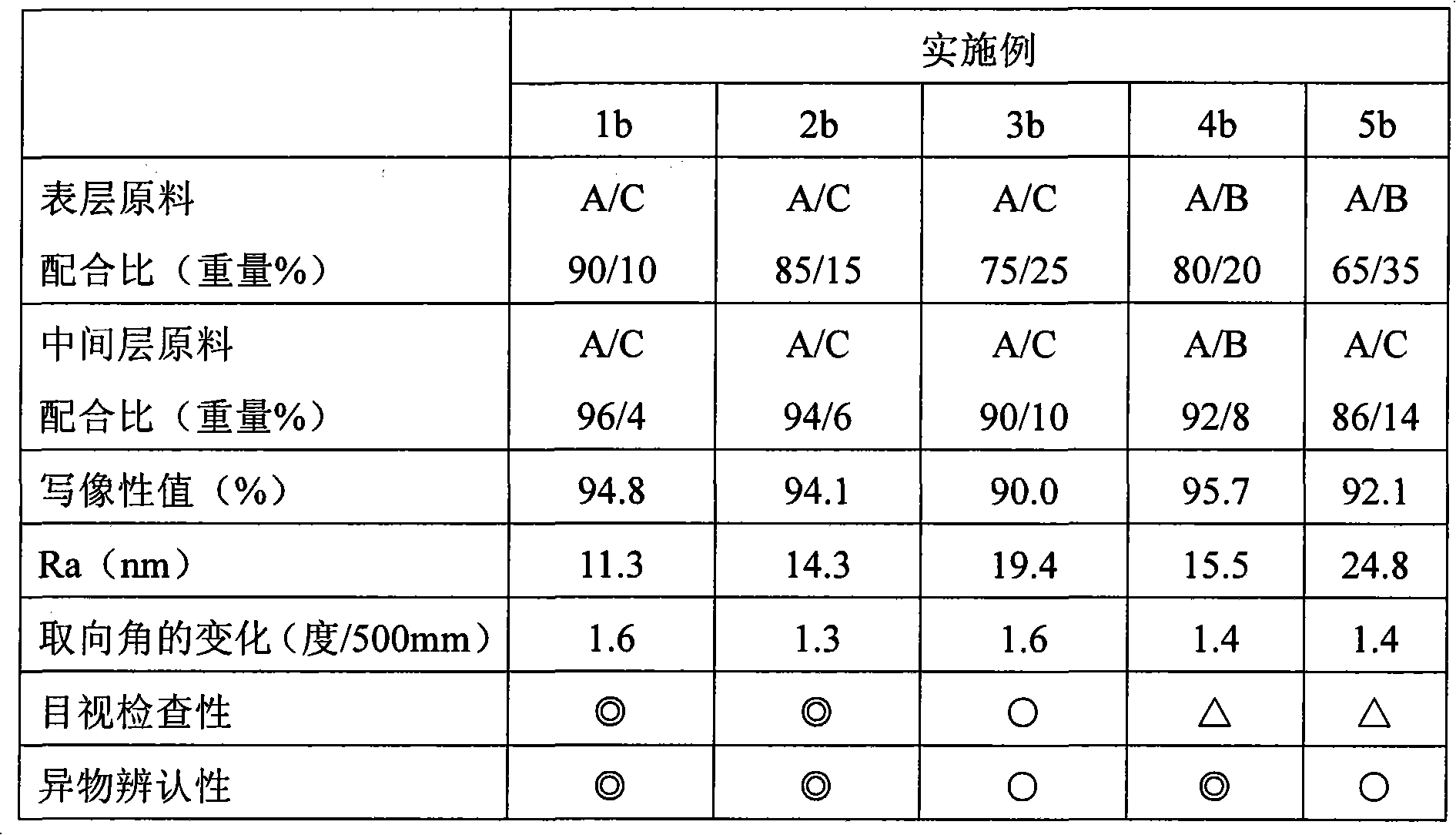

Embodiment 1b~6b and comparative example 1b~3b

[0107]

[0108] Using 100 parts by weight of dimethyl terephthalate and 60 parts by weight of ethylene glycol as starting materials, add magnesium acetate tetrahydrate as a catalyst in the reactor, set the reaction initiation temperature to 150°C, and distill off Methanol was added, and the reaction temperature was gradually increased, reaching 230°C after 3 hours. After 4 hours, the transesterification reaction was substantially completed. After adding triethyl phosphate to this reaction mixture, it moved into the polycondensation tank, added 0.04 part of antimony trioxide, and performed polycondensation reaction for 4 hours. That is, the temperature was gradually raised from 230°C to 280°C. On the other hand, the pressure was gradually reduced from normal pressure to finally reach 0.3 mmHg. After the reaction started, the reaction was stopped at a time corresponding to an intrinsic viscosity of 0.63 due to a change in the stirring power of the reaction tank, and the poly...

Embodiment 1c~6c

[0124] Embodiment 1c~6c and comparative example 1c~3c:

[0125]

[0126] Using 100 parts by weight of dimethyl terephthalate and 60 parts by weight of ethylene glycol as starting materials, add magnesium acetate tetrahydrate as a catalyst in the reactor, set the reaction initiation temperature to 150°C, and distill off Methanol was added, and the reaction temperature was gradually increased, reaching 230°C after 3 hours. After 4 hours, the transesterification reaction was substantially completed. After adding triethyl phosphate to this reaction mixture, it moved into the polycondensation tank, added 0.04 part of antimony trioxide, and performed polycondensation reaction for 4 hours. That is, the temperature was gradually raised from 230°C to 280°C. On the other hand, the pressure was gradually reduced from normal pressure to finally reach 0.3 mmHg. After the reaction started, the reaction was stopped at a time corresponding to an intrinsic viscosity of 0.63 due to a chang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com