Novel low-carbon floor

A new type of floor technology, applied in the direction of floors, buildings, building structures, etc., can solve problems such as shortage of wood, achieve the effect of protecting the environment and solving the shortage of wood resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

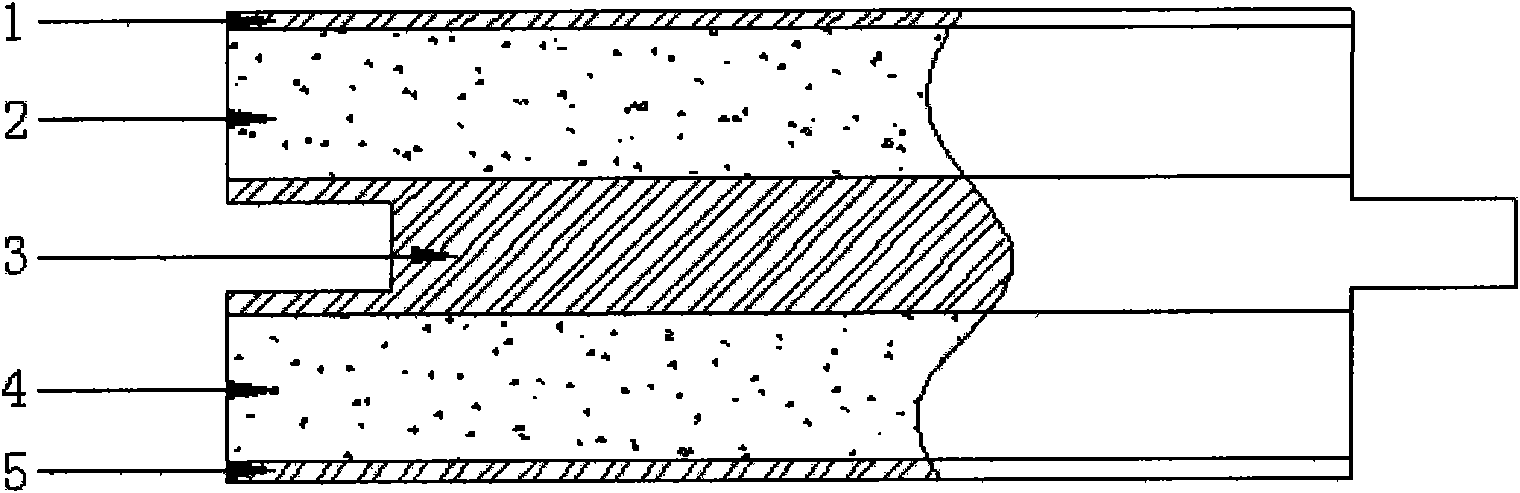

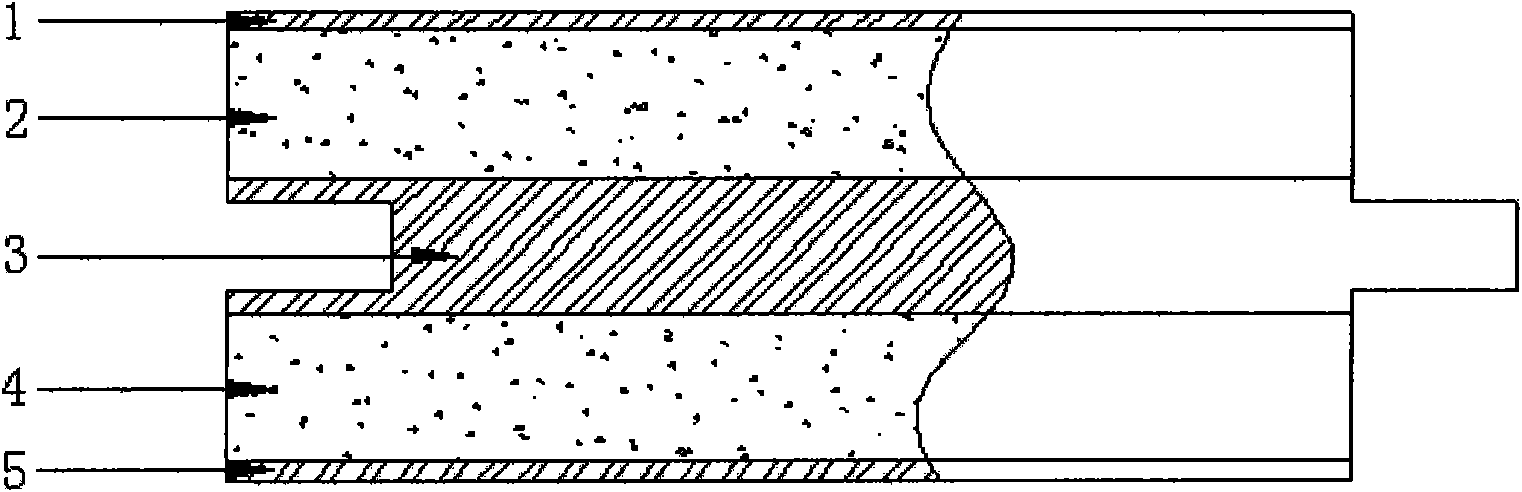

[0018] Example: such as figure 1 As shown, a new type of low-carbon floor, which includes a veneer finish layer 1, a substrate layer, and a veneer 5 in sequence. Among them, the substrate layer has a three-layer structure, which is a magnesite wood structure board composed of a magnesite gelled flame-retardant layer 2, a wood layer 3, and a magnesite gelled flame-retardant layer 4 sequentially interlayered.

[0019] The layer where the tongue and groove of the new low-carbon floor is located is the wooden layer 3. In this way, the splicing performance of the tongue-and-groove contact part of the floor can be enhanced. Compared with the case where the tongue-and-groove part is opened on the magnesite gelled flame-retardant layer, the tongue-and-groove is not easy to be damaged during processing and use.

[0020] The main components of the magnesite gelled flame retardant layer 2 are magnesium chloride and magnesium oxide, and the magnesite gelled flame retardant layer 2 is als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com