Oxygen-enrichment steam and biomass fuel combustion improver as well as synthesizing equipment and energy-saving and environmental-protection method thereof

A technology for biomass fuel and synthesis equipment, applied in chemical instruments and methods, fuels, solid fuels, etc., can solve the problems of low combustion rate of coal-fired operating equipment, combustion exhaust pollution, low environmental protection, etc., and solve the problem of exhaust waste heat utilization. , The effect of solving exhaust pollution and improving overall power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

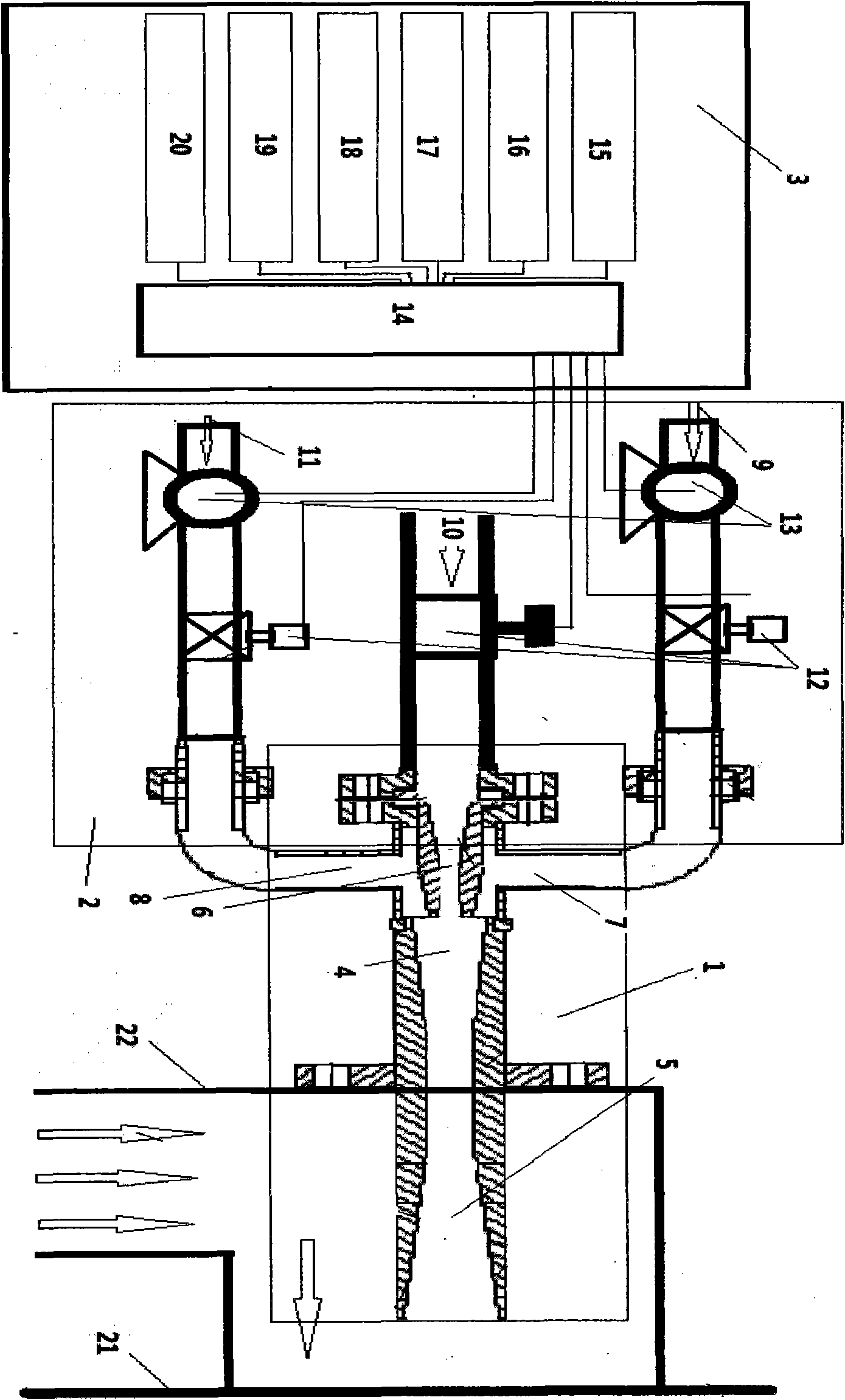

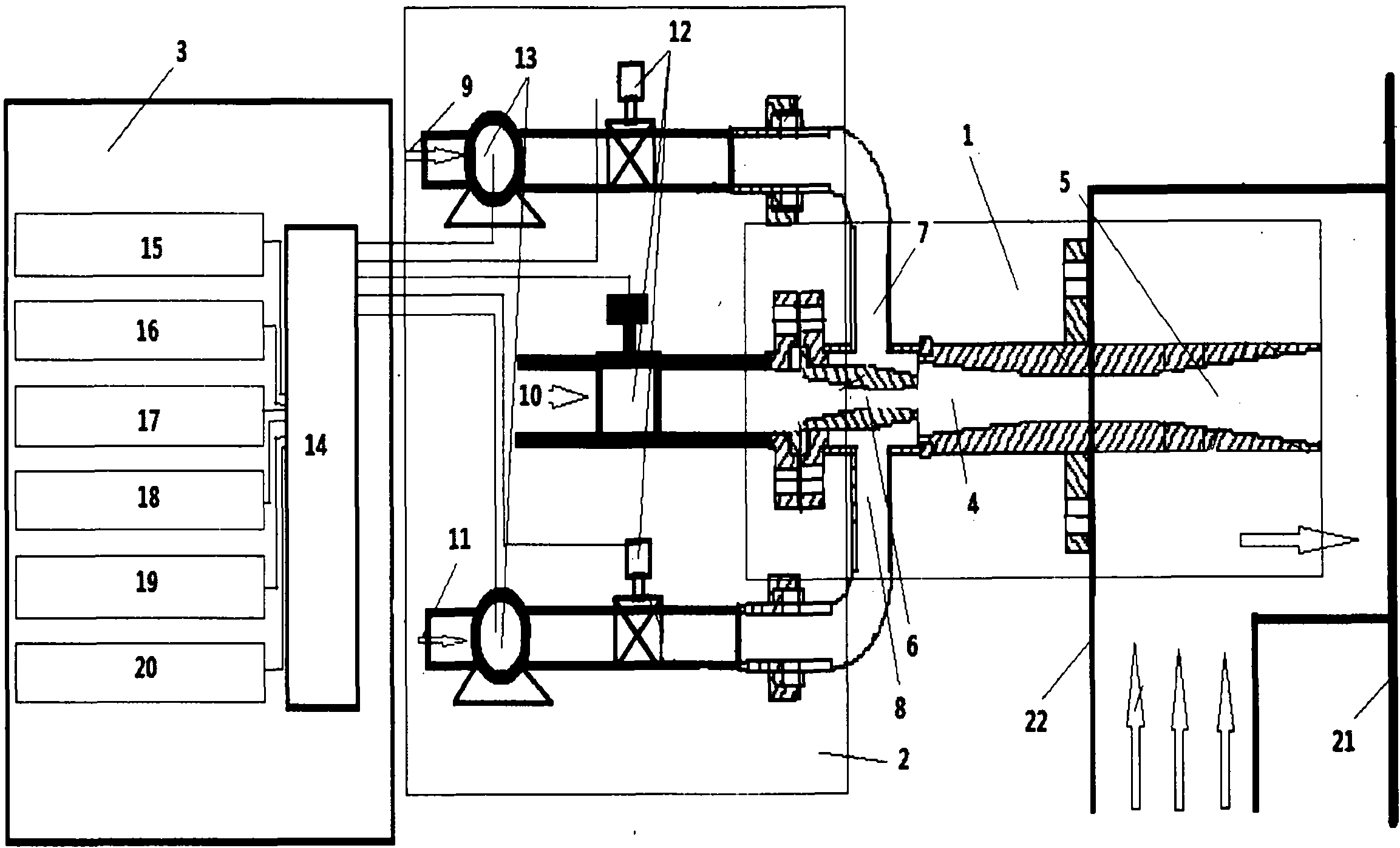

[0067] Such as figure 1 As shown, a fuel combustion aid synthesis equipment of the present invention is composed of three parts: a vaporization mixing injection gun 1, a pipeline assembly 2 and a PLC man-machine dialogue intelligent automatic combustion stabilization control equipment 3. The vaporization mixing spray gun is connected to the pipeline assembly, the vaporization mixing spray gun is provided with an electric regulating valve; the pipeline assembly is provided with an electric pump and an electric regulating valve, the electric regulating valve of the vaporization mixing spray gun and the electric pump and electric pump of the pipeline assembly The regulating valves are respectively electrically connected with PLC man-machine dialogue intelligent automatic combustion stabilization control equipment. The vaporization mixing injection gun is composed of a vaporization mixing chamber 4, an injection pipe 5 and a steam nozzle

[0068] 6. The negative pressure suction...

Embodiment 2

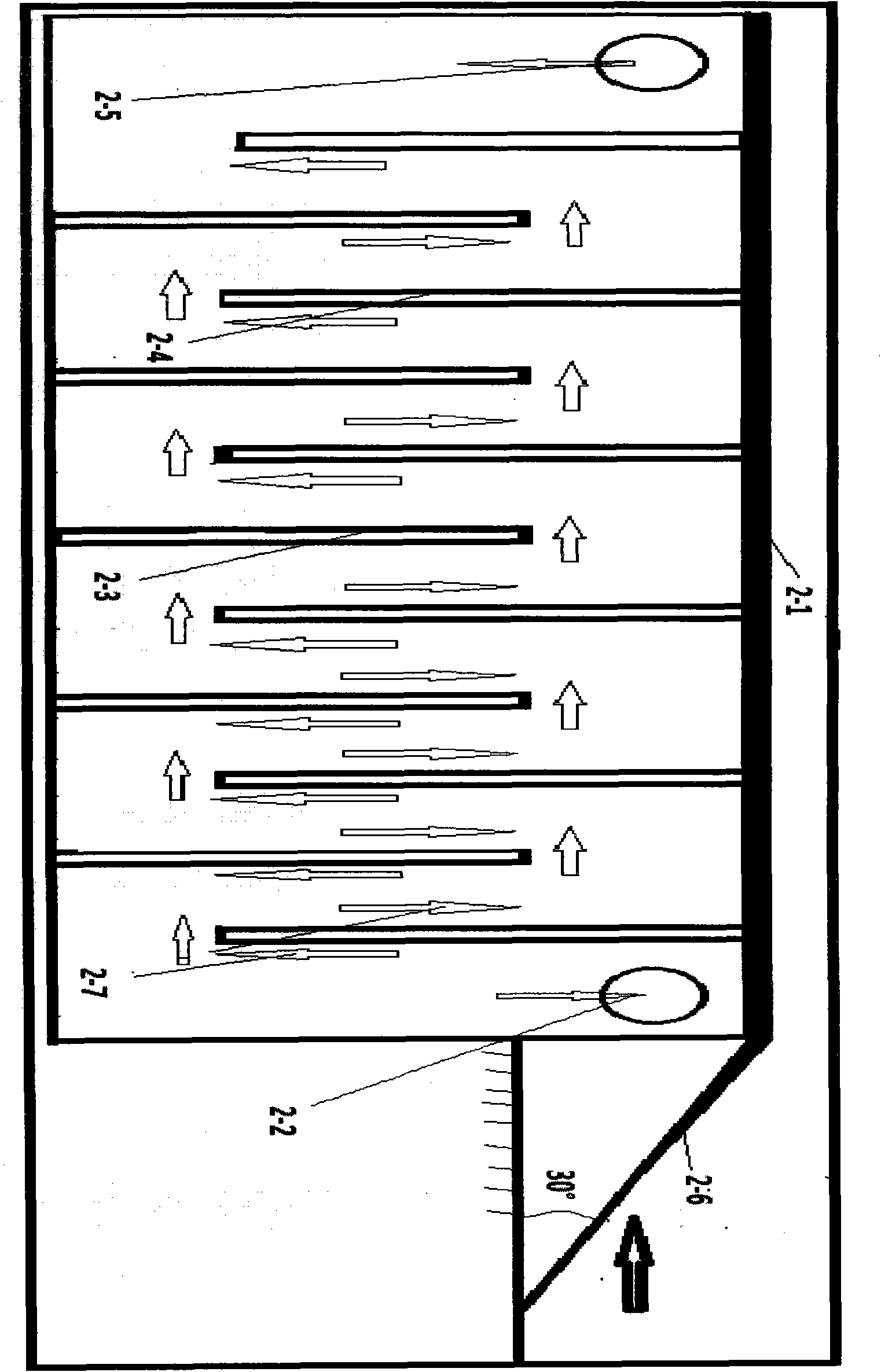

[0076] Such as figure 2 Shown, described tail gas dust removal bed equipment of the present invention, by dust removal bed bed surface 2-1, tail gas inlet 2-2, dust removal bed lower baffle plate 2-3, dust removal bed baffle plate 2-4 and tail gas outlet 2 -5, and the boarding ramps 2-6 form a closed space body; the exhaust gas enters the exhaust gas dust removal bed from the exhaust gas inlet, passes through the upper baffle and the lower baffle, and then comes out from the tail gas outlet and then enters the chimney for discharge; The waste heat of the exhaust gas is dissipated by the surface of the exhaust gas dedusting bed. In the figure, 2-7 is the traveling direction of exhaust gas.

[0077] The exhaust gas from the exhaust dust removal bed has been tested, and the total amount of harmful emissions has been reduced by more than 90%. The exhaust gas temperature is lower than 50°C.

Embodiment 3

[0079] An oxygen-enriched steam biomass fuel combustion-supporting agent, said oxygen-enriching steam biomass fuel combustion-supporting agent is composed of steam, biomass fuel and an oxygen promoter, and is directly compounded online by the synthesis equipment of Example 1 when coal is burned It is a fuel combustion-supporting agent that is ready to be mixed and sprayed, and enters the burning coal with the distribution air to support combustion; the weight ratio of the oxygen-enriched steam biomass fuel combustion-supporting agent is 1.2MPa water vapor: 50% content of methanol: 27% industrial hydrogen peroxide = 4: 3: 3; the weight ratio of the coal and the oxygen-enriched steam biomass fuel combustion enhancer is: coal: combustion enhancer = 9: 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com