Method for preparing high-gradient, high-dielectric and low-loss pressure-sensitive material

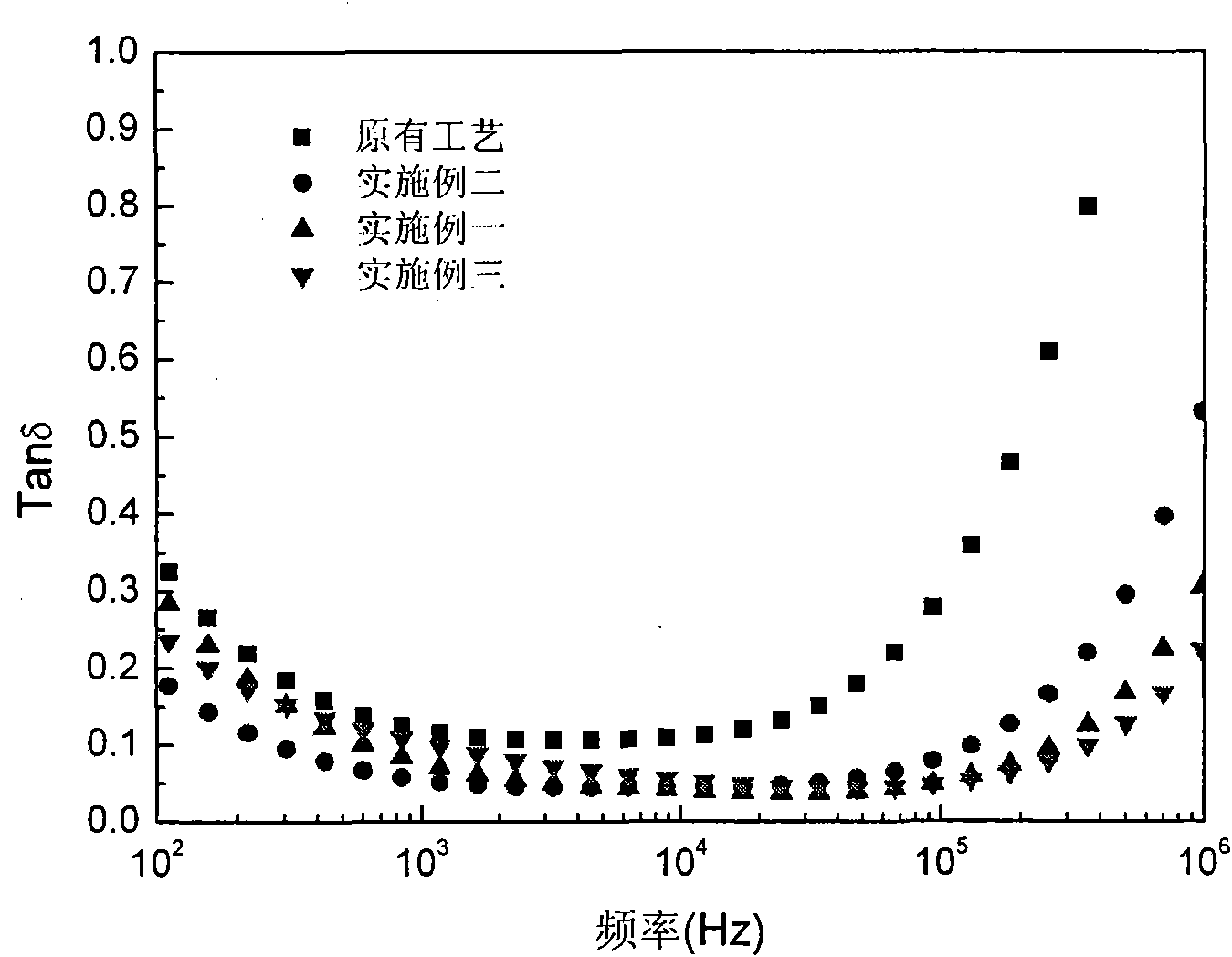

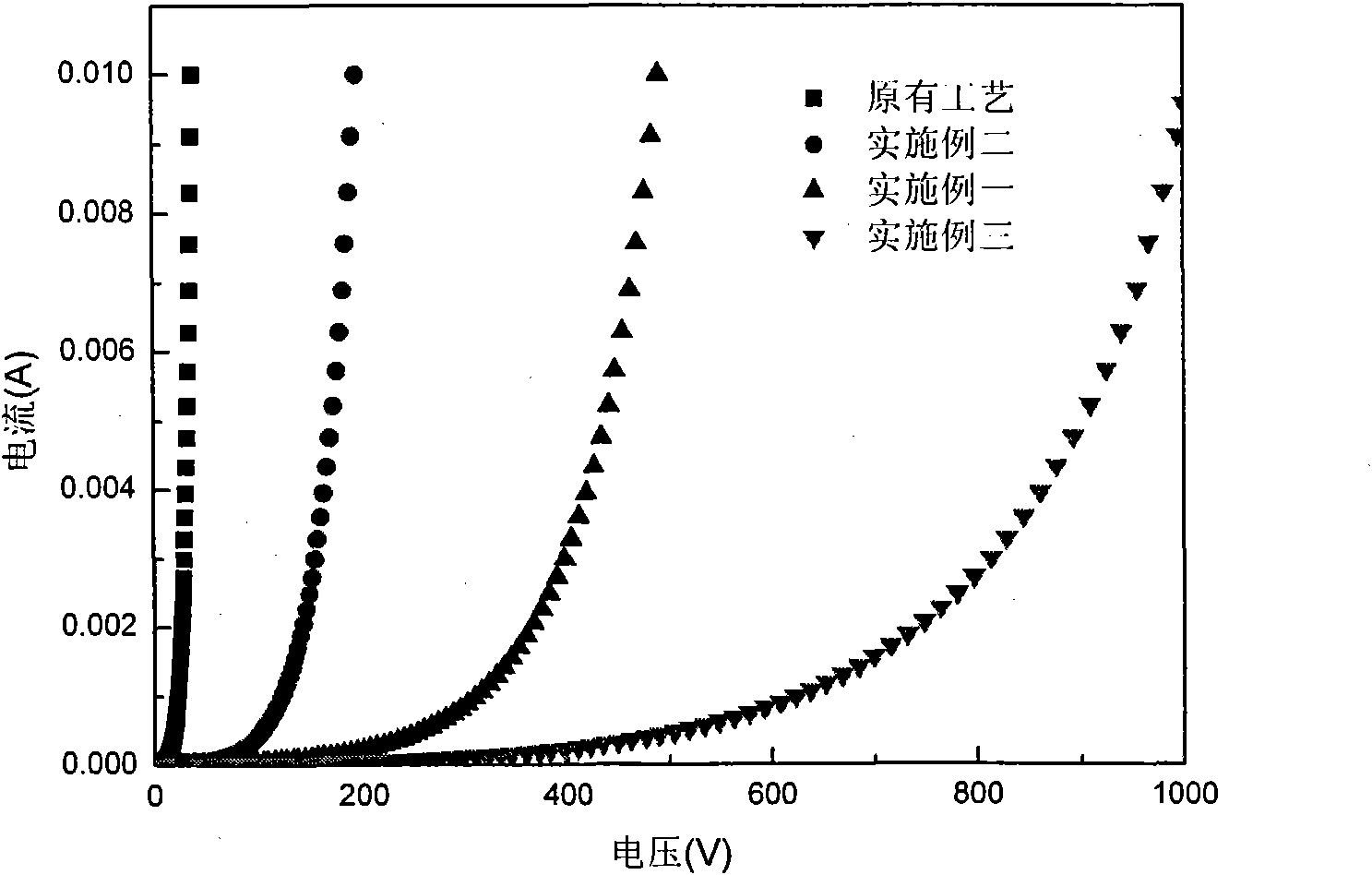

A pressure-sensitive material, high dielectric technology, applied in the preparation of high-gradient, high-dielectric and low-loss CCTO-based pressure-sensitive materials, high-gradient, high-dielectric and low-loss pressure-sensitive materials, can solve the problems of limited applications, Achieve the effects of reducing dielectric loss, increasing grain boundary resistance, and increasing voltage gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

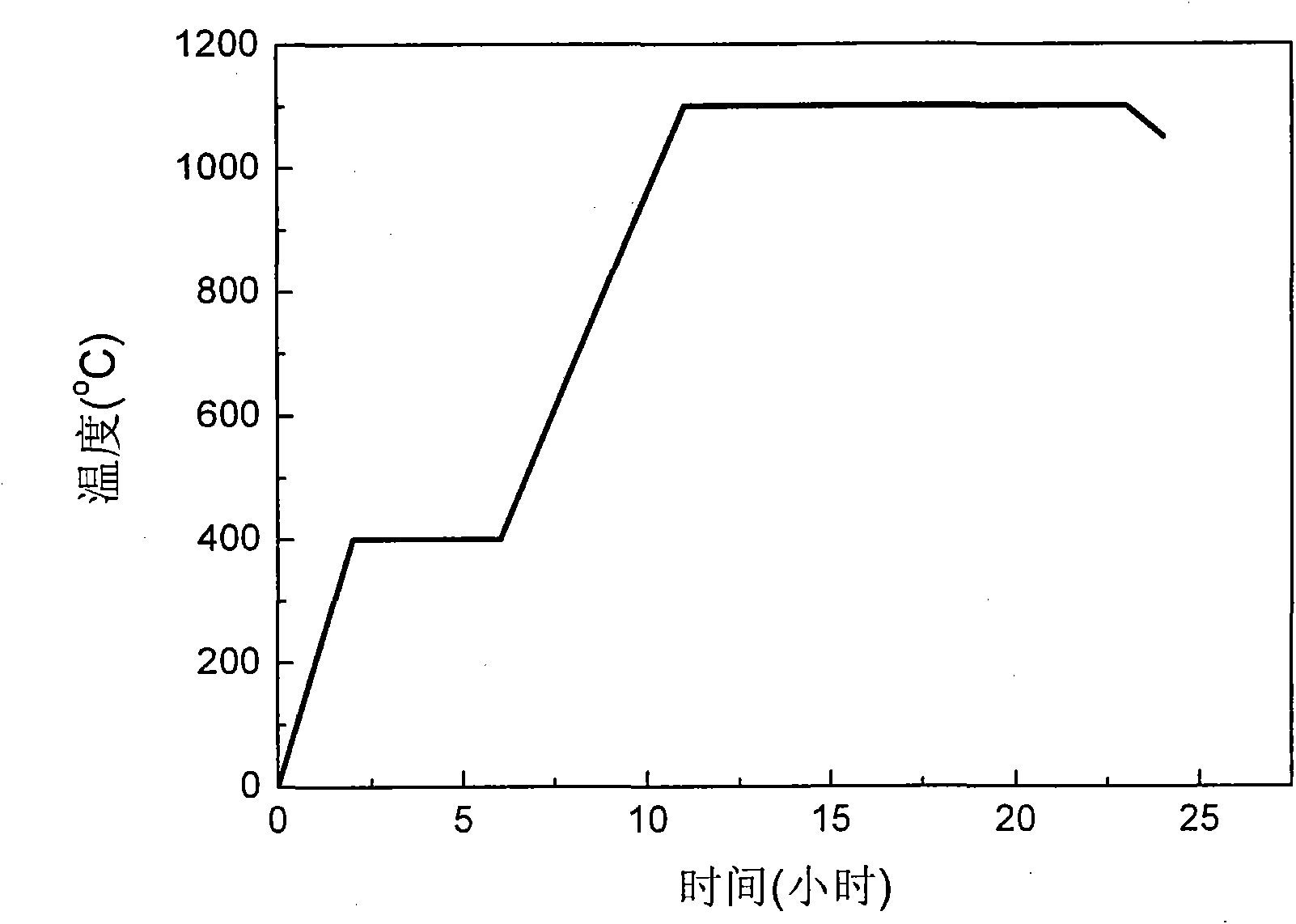

[0021] The preparation method of the high-gradient, high-dielectric and low-loss pressure-sensitive material proposed by the present invention comprises the following steps:

[0022] (1) Preparation and mixing of raw materials:

[0023] CaCO 3 or CaO, CuO, TiO 2 And PbO is raw material, and the mass ratio of each raw material is:

[0024] CaCO 3 :CuO:TiO 2 :PbO=1:(2.27~2.50):(3.03~3.35):(0.1~0.85), or CaO:CuO:TiO 2 :PbO=1:(4.05~4.48):(5.42~5.99):(0.18~1.52);

[0025] After weighing each raw material according to the above mass ratio, place it in a ball mill tank and mix and grind for 10 to 24 hours;

[0026] (2) Calcination and grinding:

[0027] The mixed and ground material is pre-fired at 800°C to 900°C for 2 to 12 hours, and cooled with the furnace;

[0028] Crush the pre-calcined material, put it in a ball mill tank and grind it with alcohol as the grinding medium for 12-24 hours, put the ground slurry in a drying oven to dry, and pass through a 100-200 mesh sieve...

Embodiment 1

[0035] According to the preparation method of the present invention, the actual preparation of high-gradient, high-dielectric and low-loss CCTO-based varistor ceramics is carried out. The varistor voltage gradient of the material prepared according to this process is about 300V / mm.

[0036] (1) Preparation and mixing of raw materials:

[0037] The CCTO material uses CaO, CuO, TiO 2 As the initial raw material, the mass ratio of each raw material is CaO:CuO:TiO 2 :PbO=1:4.26:5.71:0.36.

[0038] The raw materials were dry-milled in a ball mill jar for 24 hours.

[0039] (2) Calcination and grinding:

[0040] The dried material was placed in a high-temperature electric furnace, and pre-fired at 900 degrees Celsius for 2 hours. Cool in the furnace.

[0041] The powder agglomerates after pre-firing. Crush the hard block after pre-burning and place it in a ball mill jar, and grind for 24 hours with alcohol as the grinding medium. The ground slurry is placed in a drying oven ...

Embodiment 2

[0051] According to the preparation method introduced in the present invention, the actual preparation of high-gradient, high-dielectric and low-loss CCTO-based varistor ceramics is carried out. The varistor voltage gradient of the material prepared according to this process is about 100V / mm.

[0052] (1) Preparation and mixing of raw materials:

[0053] The CCTO material uses CaCO 3 , CuO, TiO 2 As the initial raw material, the mass ratio of each raw material is CaCO 3 :CuO:TiO 2 :PbO=1:2.385:3.193:0.1.

[0054] The raw materials were placed in a ball mill jar and mixed with alcohol as the grinding medium for 12 hours. The ball-milled slurry is placed in a drying oven for drying.

[0055] (2) Calcination and grinding:

[0056] The dried material was placed in a high-temperature electric furnace, and pre-fired at 900 degrees Celsius for 4 hours. Cool in the furnace.

[0057]The powder agglomerates after pre-firing. Crush the hard block after pre-burning and place it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com