High-efficiency ultraviolet sterilizer

A technology of ultraviolet disinfection and sterilizer, applied in the field of disinfection devices, can solve the problems of casing pollution, disinfection efficiency, improvement, etc., and achieve the effects of reducing ultraviolet reflectivity, simple structure, and excellent corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

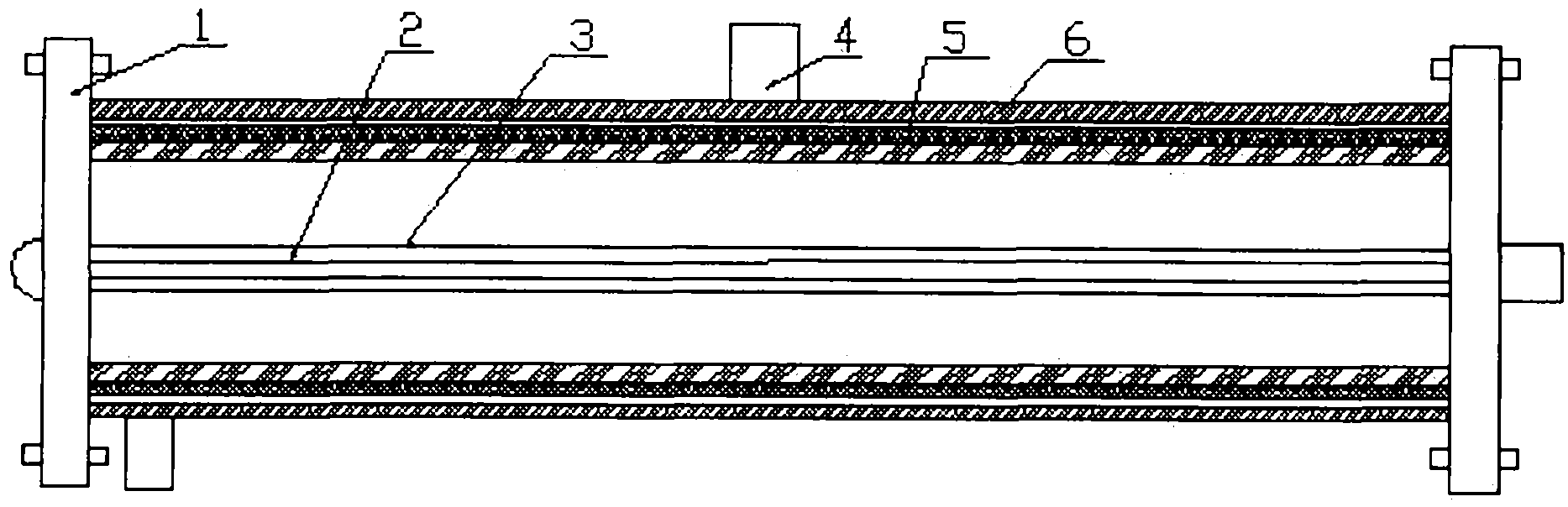

Image

Examples

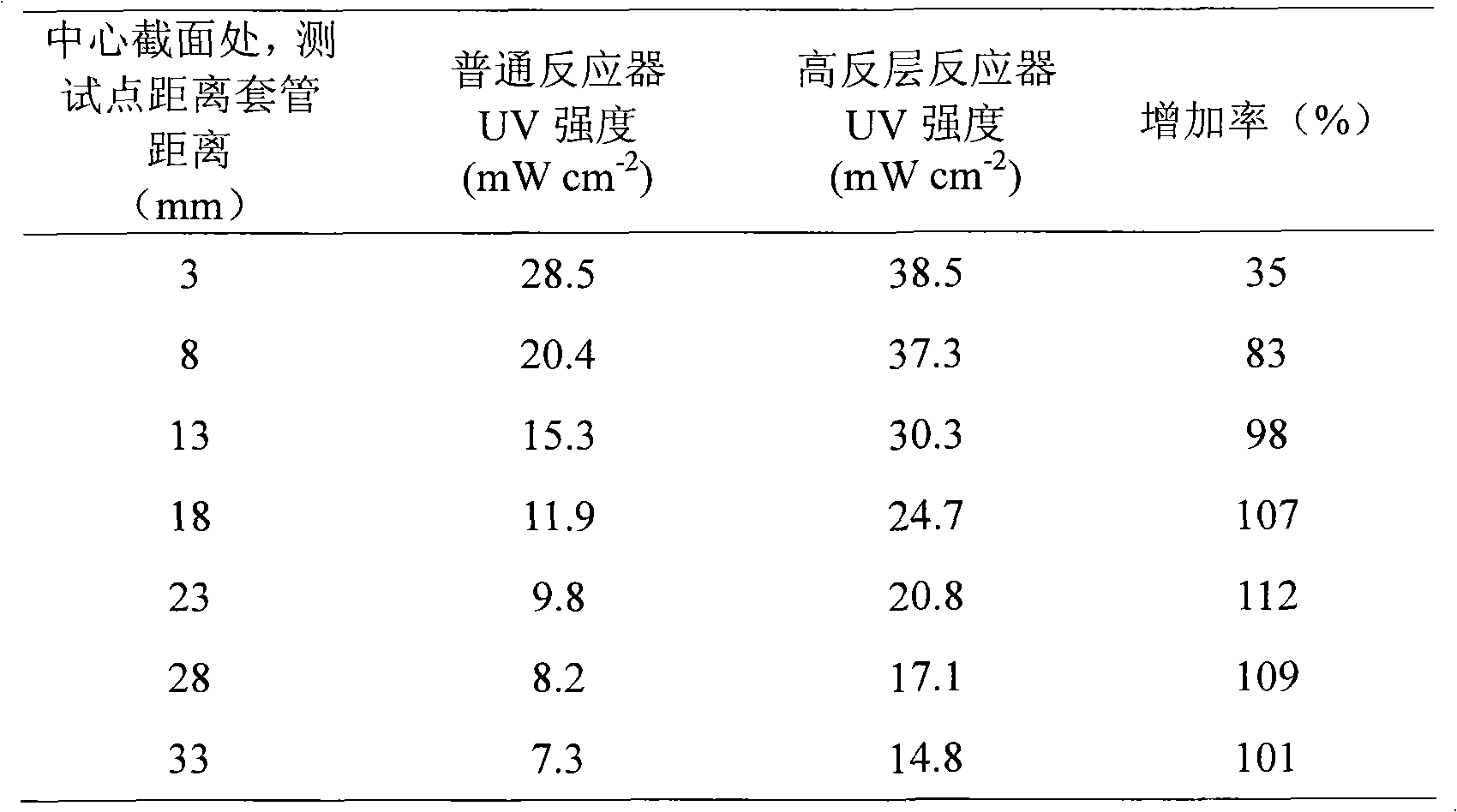

Embodiment 1

[0019] The quartz glass tube coated with aluminum film is used as the ultraviolet reflection layer, wherein the aluminum film is vapor-deposited on the outer wall of the quartz glass tube to prevent the aluminum film from being corroded by water, and the thickness of the aluminum film is 0.2mm. The test was carried out on the cavity ultraviolet intensity test device based on the fluorescent glass probe, and the ultraviolet intensity distribution in the cavity of the common sterilizer with the same size and the sterilizer with an ultraviolet reflective layer was compared and measured. The test device is in the shape of a vertical barrel (inner diameter 95mm, height 400mm), with a low-pressure mercury lamp (pre-aged for more than 100 hours) installed in the center. The diameter is 23mm. The medium in the cavity is air. It can be seen from Table 1 that the ultraviolet intensity of the aluminum high-reflection layer sterilizer has a greater increase in the air medium.

[0020] T...

Embodiment 2

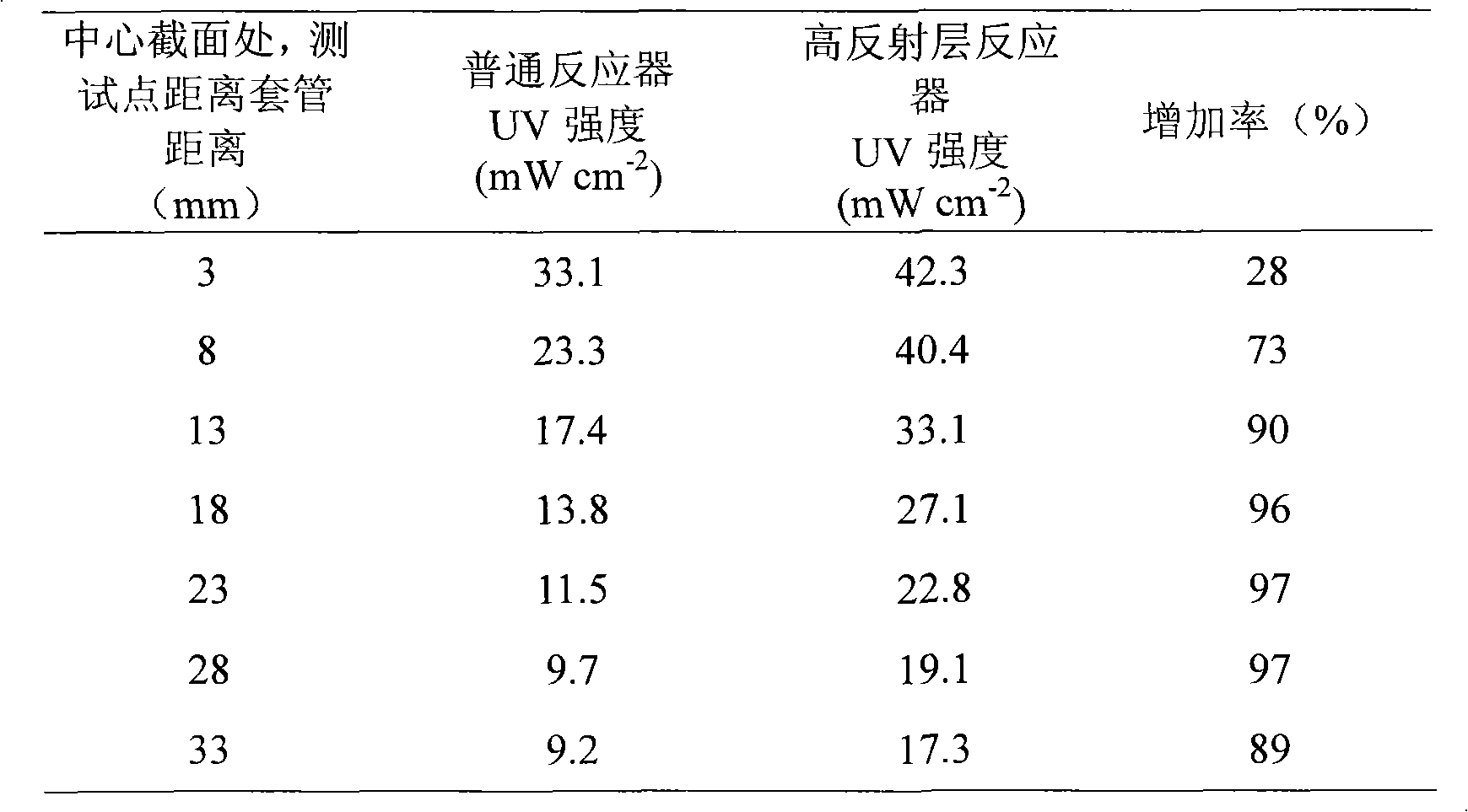

[0023] The quartz glass tube coated with aluminum film is used as the ultraviolet reflection layer, in which the aluminum film is evaporated on the outer wall of the quartz glass tube to avoid the aluminum film from being corroded by water. The thickness of the aluminum film is 0.2mm. UV intensity distribution. The aqueous solutions with different ultraviolet transmittances are prepared from potassium hydrogen phthalate and deionized water, and the transmittances at 254nm are respectively 95% (measured by HACH 5000 spectrophotometer). It can be seen from Table 2 that the ultraviolet intensity of the aluminum high-reflection layer sterilizer also increases to a large extent in the water medium.

[0024] Table 2 Comparison of internal ultraviolet intensity distribution of ordinary and aluminum high-reflection layer ultraviolet sterilizers in water medium

[0025]

Embodiment 3

[0027] Teflon is used as the ultraviolet reflective layer, lining the inner wall of the sterilizer (304 stainless steel tube). Using a fluorescent glass probe, compare and measure the ultraviolet intensity distribution inside the cavity of a common sterilizer of the same size and a PTFE-lined high-reflection layer sterilizer. As can be seen from Table 3, the ultraviolet intensity inside the PTFE-lined high-reflection layer sterilizer has increased to a greater extent.

[0028] Table 3 Comparison of UV intensity distribution inside ordinary and PTFE high-reverse layer sterilizers in air medium

[0029]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com