Preparation method of multistage pore canal SAPO-11 (silicoaluminophosphate-11) molecular sieve and application thereof in gasoline modification

A technology of SAPO-11 and molecular sieve, which is applied in the direction of molecular sieve and alkali-exchanged phosphate, molecular sieve characteristic silicoaluminophosphate, refined hydrocarbon oil, etc., can solve the problem of less SAPO-n molecular sieve, and achieve improved selectivity and effective removal , the effect of high multi-branched isomer selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1 Synthesis of SAPO-11 by adding TDPA

[0027] Stir 0.34 n-tetradecyl organophosphoric acid (TDPA) and 30 g deionized water uniformly in a water bath at 35°C for 0.5 h, then add 4.40 g of phosphoric acid (AR, 85%), stir for 0.5 h, then add 9 g of pseudoboehmite After continuing to stir in a water bath at 35°C for 4h, slowly add 7.9g of di-n-propylamine (abbreviated as DPA, AR, 99%), and after continuing to stir for 2h, add 1.3g of ethyl orthosilicate (AR, 99%), Continue stirring for 2h to obtain the reaction sol (mixed solution), the mol ratio of the material contained in the reaction sol system is Al 2 o 3 :P 2 o 5 : SiO 2 :DPA:H 2 O:TDPA=1:0.92:0.3:1.2:80:0.06;

[0028] The reaction sol was put into a polytetrafluoroethylene high-pressure reactor, and after crystallization at 185°C for 48 hours, the solid product was separated by centrifugation, washed with deionized water to pH = 7-8, and dried at 120°C for 6 hours to obtain SAPO- 11 molecular sieve ra...

Embodiment 2

[0034] Example 2 Synthesis of SAPO-11 by adding n-DPA

[0035] 0.34g TDPA among the embodiment 1 is changed into 0.27g n-decyl organic phosphoric acid (being called for short n-DPA), and the mol ratio of the material contained in the reaction sol system is Al 2 o 3 :P 2 o 5 : SiO 2 :DPA:H 2 O: n-DPA = 1: 0.92: 0.3: 1.2: 80: 0.06, the crystallization time was 48 h, and the rest of the operating conditions were the same as in Example 1 to obtain SAPO-11 molecular sieve.

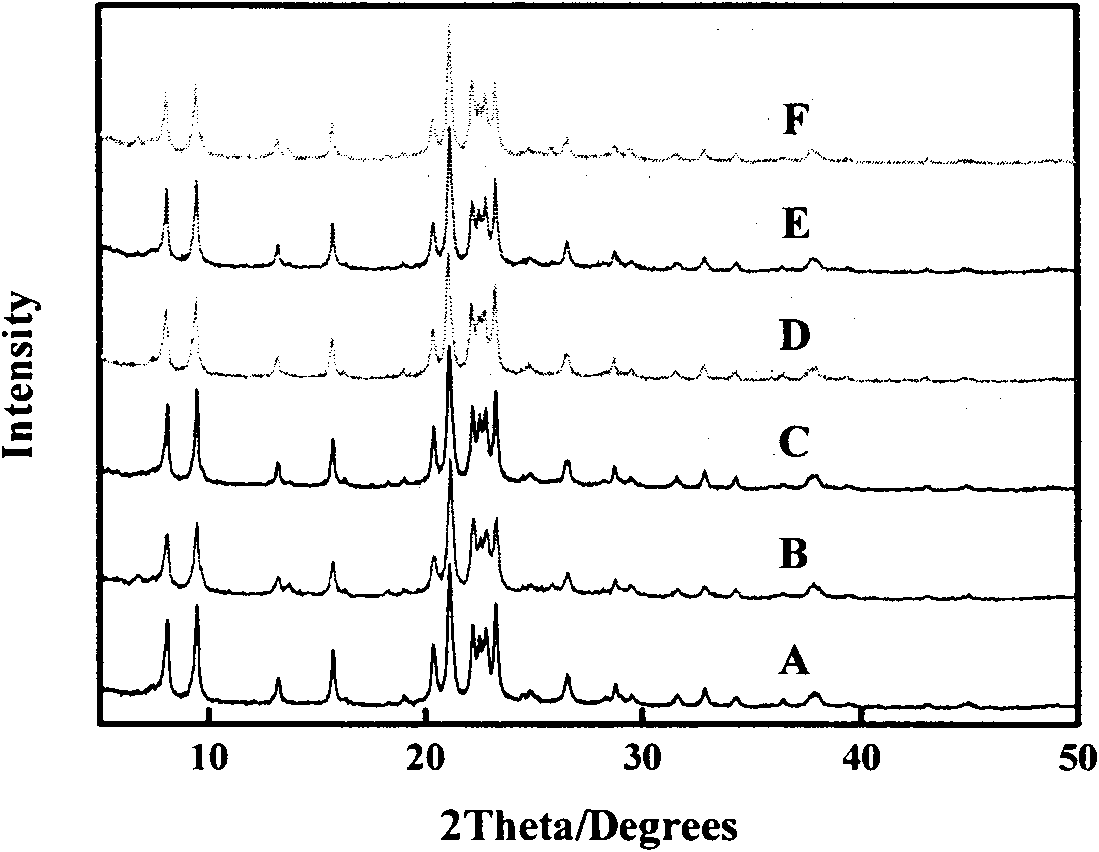

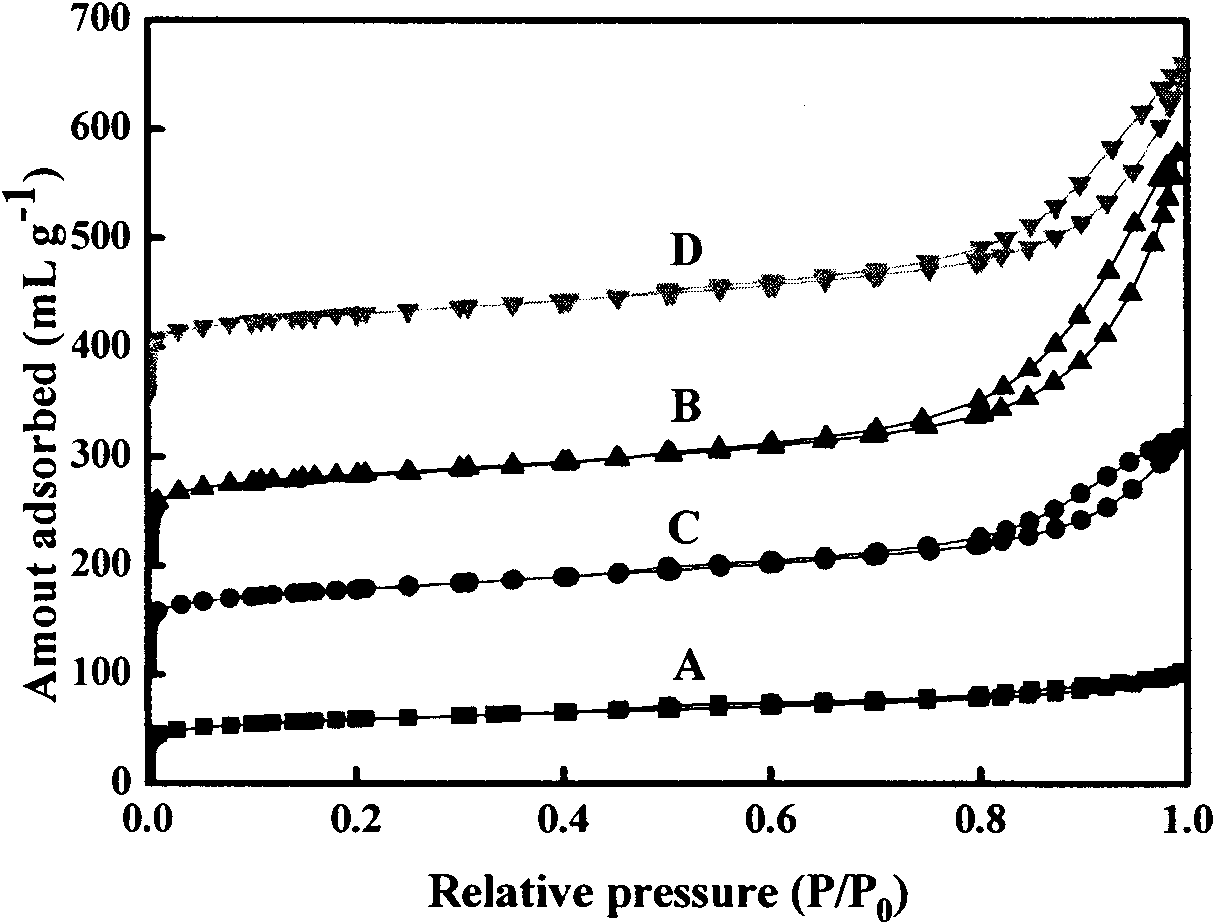

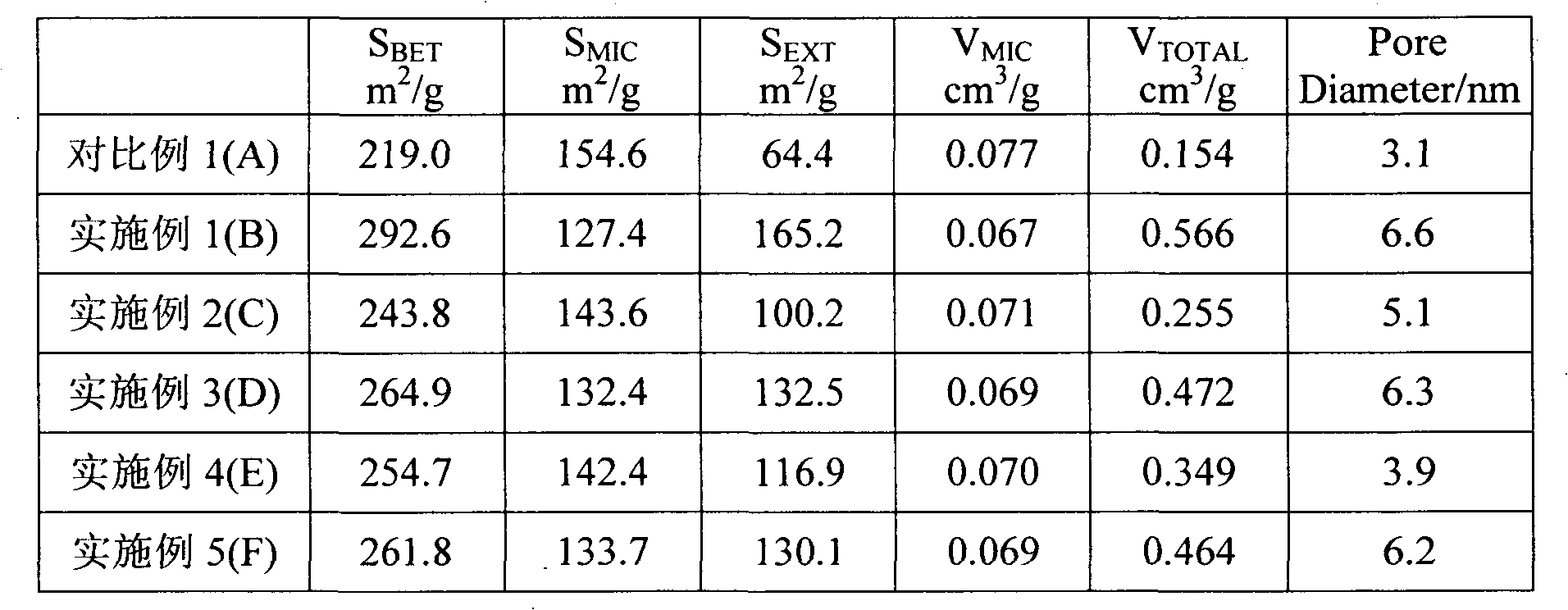

[0036] The X-ray diffraction spectrum figure of the obtained SAPO-11 molecular sieve is shown in figure 1 In the curve C, the pore structure data are shown in Table 1, and the nitrogen adsorption and desorption are as follows: figure 2 Shown in curve D.

Embodiment 3

[0037] Example 3 Synthesis of SAPO-11 by adding ODPA

[0038] 0.34g TDPA in embodiment 1 is changed into 0.41g ODPA, and the mol ratio of the material contained in the reaction sol system is Al 2 o 3 :P 2 o 5 : SiO 2 :DPA:H 2 O: ODPA = 1: 0.92: 0.3: 1.2: 60: 0.06, the crystallization time was 48 h, and the rest of the operating conditions were the same as in Example 1 to obtain SAPO-11 molecular sieve.

[0039] The X-ray diffraction spectrum figure of the obtained SAPO-11 molecular sieve is shown in figure 1 In the curve C, the pore structure data are shown in Table 1, and the nitrogen adsorption and desorption are as follows: figure 2 Shown in curve D.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com