Efficient continuous process for pollution-free recovery of precious metals by a dielectrophoresis method

A technology of dielectrophoresis and precious metals, applied in the field of chemical process and separation, can solve the problems of low particle concentration, low degree of industrial automation, low separation efficiency, etc., and achieve the effect of reducing environmental pollution and reducing electrothermal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with embodiment, the present invention is further described; Following embodiment is illustrative, not limiting, can not limit protection scope of the present invention with following embodiment.

[0022] A high-efficiency continuous process for recovering precious metals without pollution by dielectrophoresis, the steps are:

[0023] 1. Mixing is carried out in the mixing box.

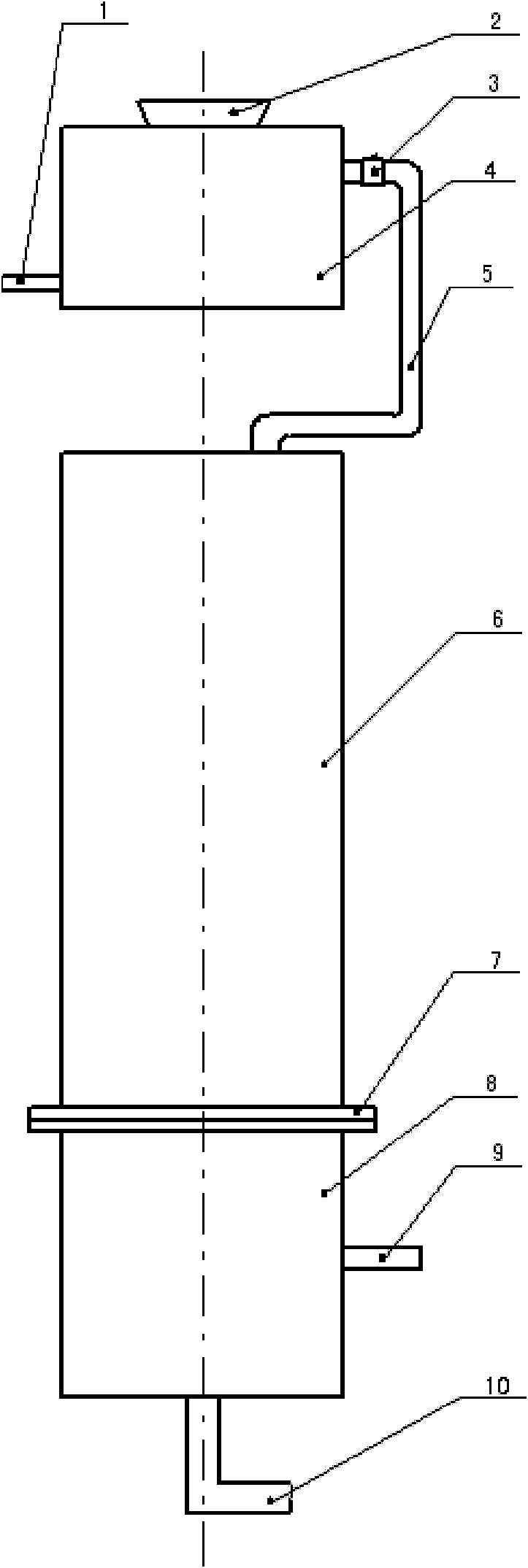

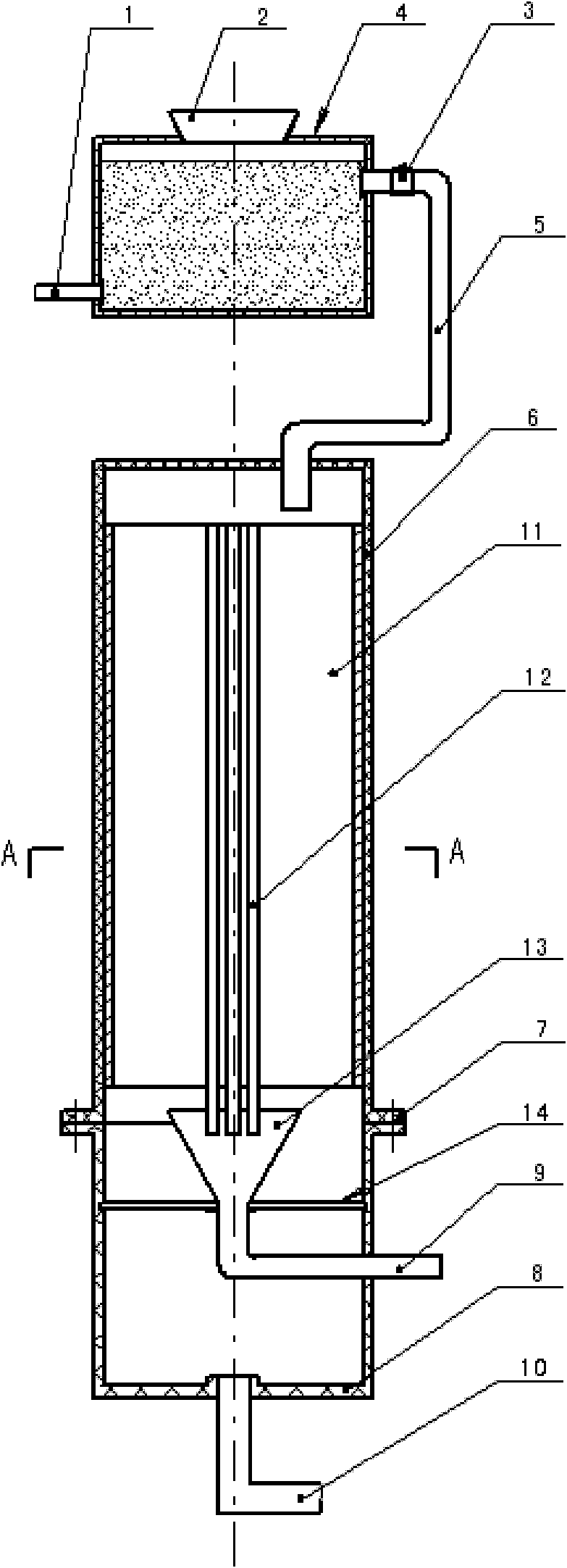

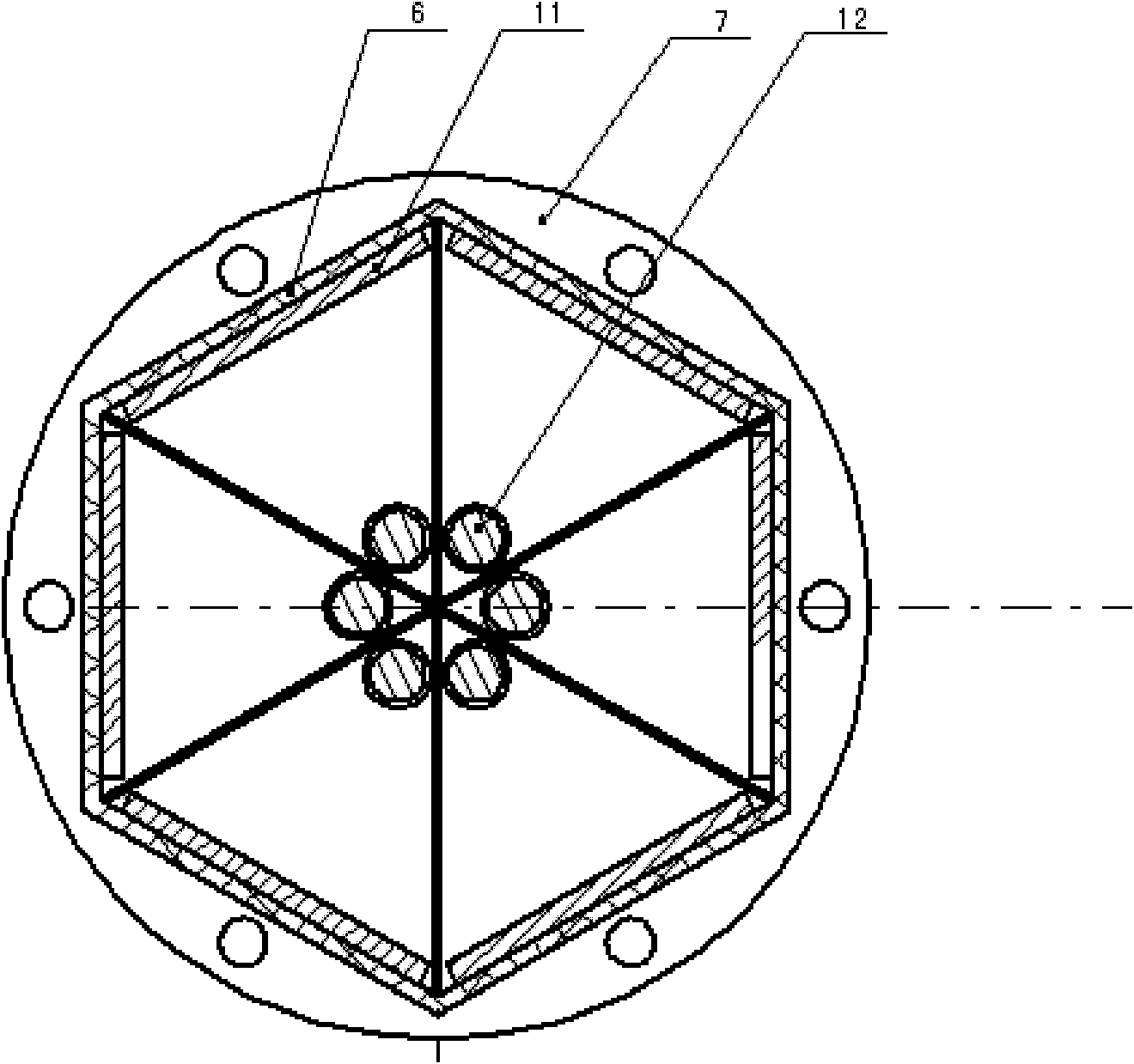

[0024] The separated material is put into the mixing box 4 through the feed port 2, and the lower part of the mixing box is provided with a water inlet pipe 1, through which water is pumped into the mixing box, and the water under pressure is used to drain the water in the mixing box. The separated material is washed into a suspension, and a discharge pipe 5 is also arranged on the mixing box, and the suspension enters the dielectrophoresis separation chamber through the discharge pipe. There is a valve 3 on the discharge pipe to control that the suspension cannot enter th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com