Elastomeric compositions comprising hydrocarbon polymer additives

A technology of hydrocarbon polymers and compositions, applied in the field of hydrocarbon polymer additives in the field of cured elastomer compositions, can solve the problems of reducing tire wet traction performance, reducing tear strength, reducing dynamic performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0123] The elastomer composition comprising at least one elastomer and a hydrocarbon polymer additive will now be further described with reference to the following non-limiting examples.

[0124] The curing performance was measured using MDR 2000 from Alpha Technologies, Inc. according to ASTM D-2084 at the indicated temperature and 0.5 degree arc. The sample is cured at the indicated temperature (usually 150°C-160°C), and the time (minutes) corresponds to t90 + appropriate mold hysteresis. When possible, standard ASTM tests are used to determine the physical properties of the cured compound. Use Instron 4202 or Instron series IX automatic material testing system 6.03.08 to measure stress / strain performance (tensile strength, elongation at break, modulus value, energy at break) at room temperature. Tensile strength measurement is performed at ambient temperature; the sample (dog-bone shape) has a width of 0.25 inches (0.62 cm) and a length of 1.0 inches (2.5 cm) (between two tab...

Embodiment 1

[0146] In Example 1, a model silica tread compound was prepared. The compound was prepared using a Krupp 1.0 liter capacity laboratory mixer with intermeshing rotors. The non-productive mixing cycle is as follows: 1) Set the mixer rotor speed at 80 RPM with a punch (ram) pressure of 60 psi; 2) Add elastomer, all silica, silane coupling agents, oil or hydrocarbon polymer additives , And free powder, lower the punch; 3) Mix to a temperature of 160°C or 5 minutes maximum and then discharge the batch from the mixer. The productivity or the second stage and the vulcanization system components are added to the mixer. The compound was mixed in a mixer to 100°C-105°C or 90 seconds, discharged, and then tableted on a 2-roll mill.

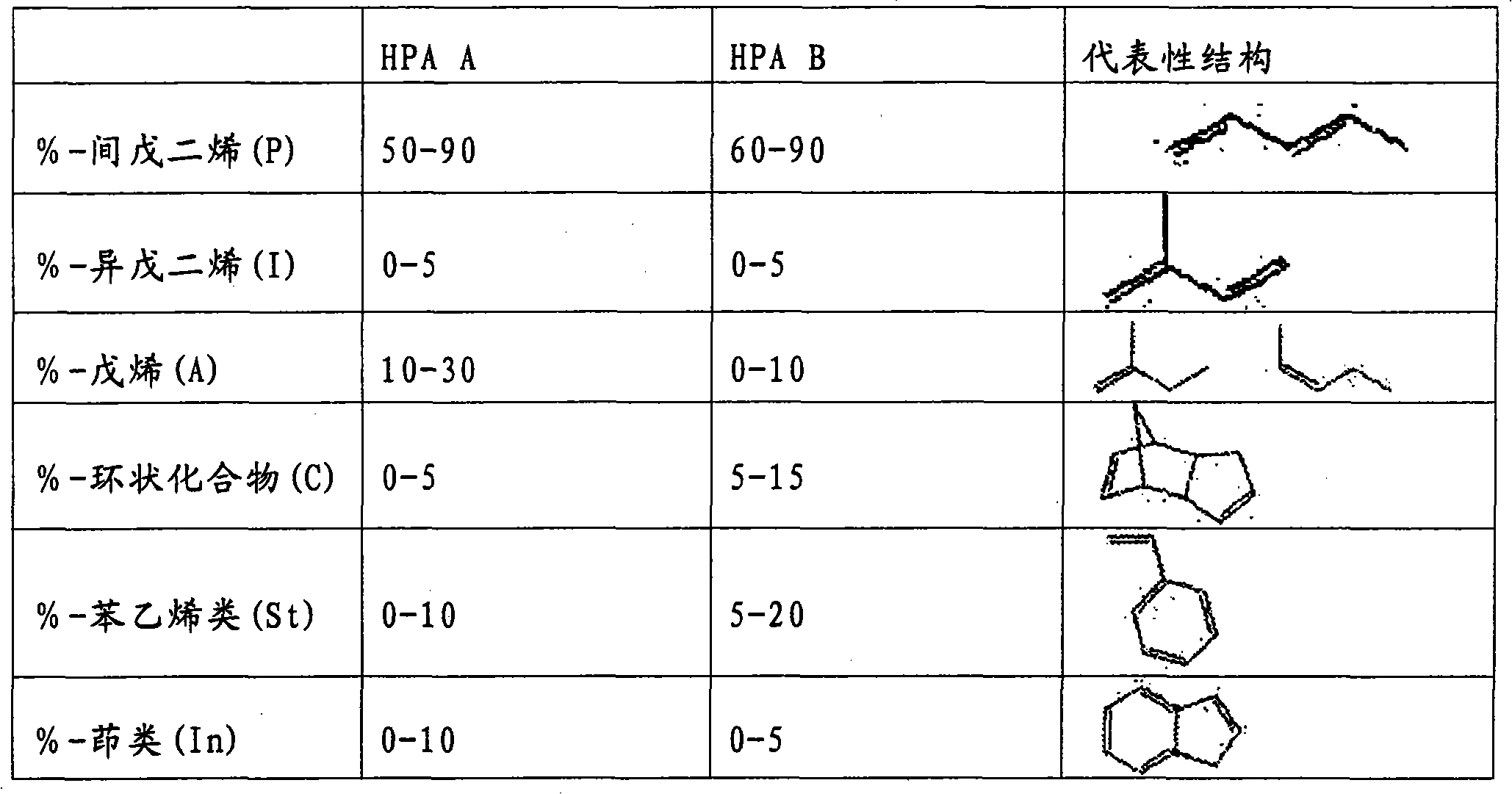

[0147] The formulation of the model silica tread compound of Example 1 is listed in Table 5, with all amounts listed in phr. In Compounds 2 and 3, hydrocarbon polymer additives (HPA A and HPA B) were used instead of aromatic oil. Hydrocarbon polymer additiv...

Embodiment 2

[0156] In Example 2, a model carbon black loaded tread compound was prepared. Two hydrocarbon polymer additives, HPA A and HPA B, were added to replace the naphthenic oil or aromatic oil in Compounds 3 and 4. The formulation of the model carbon black loaded tread compound is listed in Table 7; all amounts listed are in phr.

[0157] Table 7-Tread compound loaded with model carbon black

[0158] Compound

1

2

3

4

Natural rubber (SMR

20)

30.00

30.00

30.00

30.00

SSBR 20%

B.S.

70.00

70.00

70.00

70.00

N234

75.00

75.00

75.00

75.00

1.50

1.50

1.50

1.50

TMQ

1.00

1.00

1.00

1.00

6PPD

3.00

3.00

3.00

3.00

2.00

2.00

2.00

2.00

ZnO

3.00

3.00

3.00

3.00

Aromatic oil

40.00

Naphthenic oil

40.00

HPA A

45.00

HPA B

45.00

CBS

1.75

1.75

1.75

1.75

DPG

0.40

0.40

0.40

0.40

1.50

1.50

1.50

1.50

PVI

0.10

0.10

0.10

0.10

[0159] The compound was mixed using a Farrel BR size laboratory intern...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| melt viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com