Light-emitting diode (LED) electrode structure for effectively utilizing current and manufacturing method thereof

A technology of electrode structure and manufacturing method, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems of light shading, ineffective use of injected current, large chip area ratio, etc., to achieve simple operation, improve LED luminous efficiency, and reliability The effect of high sexual stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

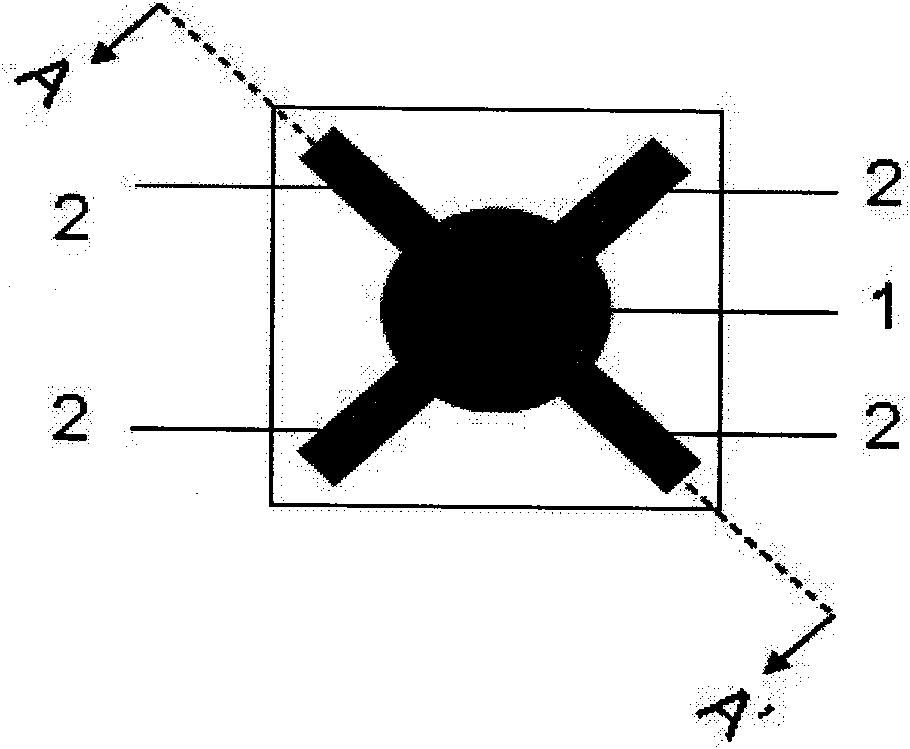

[0020] The LED electrode structure for effective current utilization of the present invention is that a part of the non-ohmic contact area is provided under the LED electrode. the following to figure 1 The known cross-shaped electrode shown is taken as an example to illustrate the LED electrode manufacturing method of the present invention.

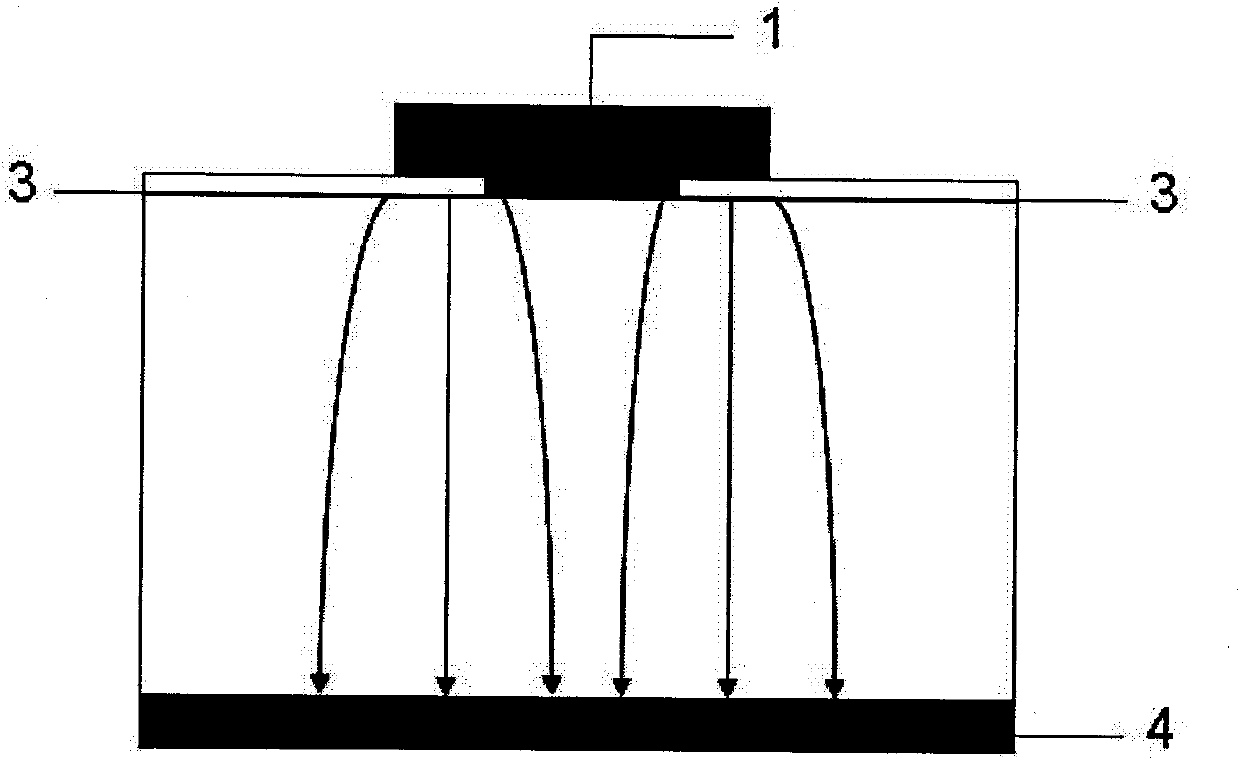

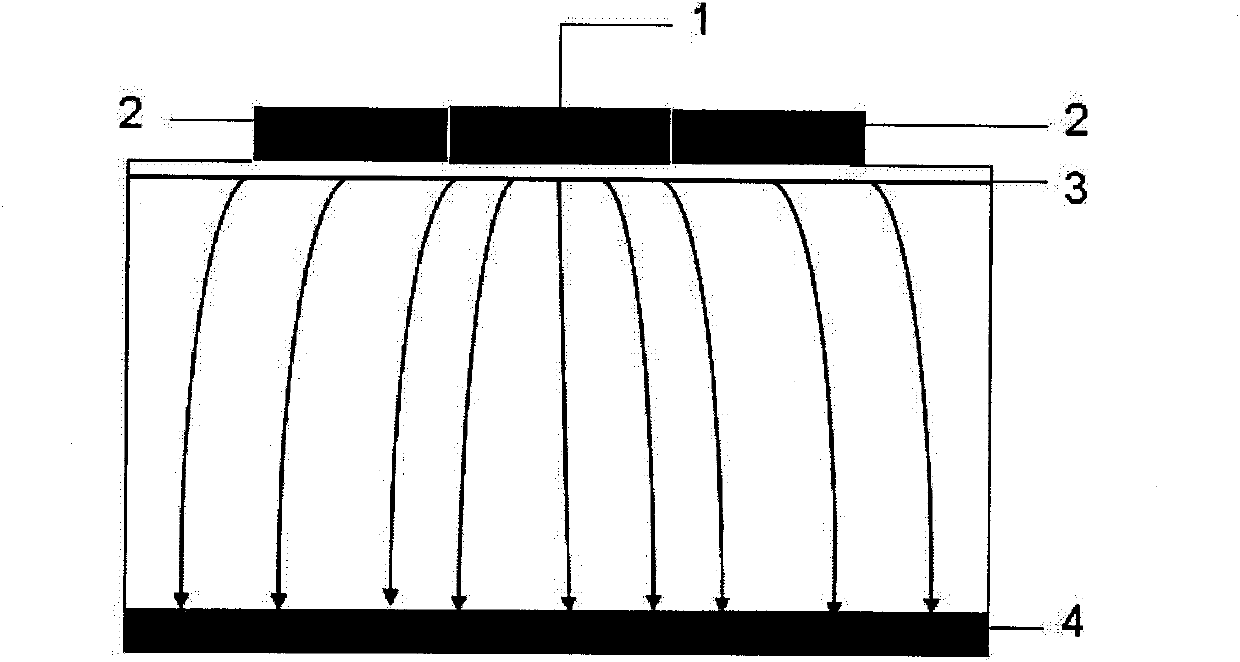

[0021] First, in image 3 On the ohmic contact layer 3 of the LED shown, the pattern of the part of the ohmic contact layer 3 to be removed is photoetched at the position where the first electrode 1 is to be made, and then this part of the ohmic contact layer is removed by a conventional wet or dry method. The material of the contact layer can be gallium phosphide, gallium arsenide, gallium nitride, gallium arsenide phosphide, gallium phosphide nitride, etc. Taking gallium arsenide as an example, put the chip into the volume ratio of hydrogen peroxide: ammonia water: water = 1: Shake up and down in the 5:1 gallium arsenide etching solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com