Method for manufacturing transparent thin-film solar cell component

A solar cell and manufacturing method technology, which is applied to electrical components, circuits, semiconductor devices, etc., can solve the problems that cannot be used as photovoltaic building integration and agricultural greenhouse roofs, complex manufacturing processes, waste of raw materials, etc., and achieves a simple and easy manufacturing process. industry, broad market prospects, and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below with reference to the drawings and specific embodiments, however, the embodiments should not be interpreted in a limiting manner.

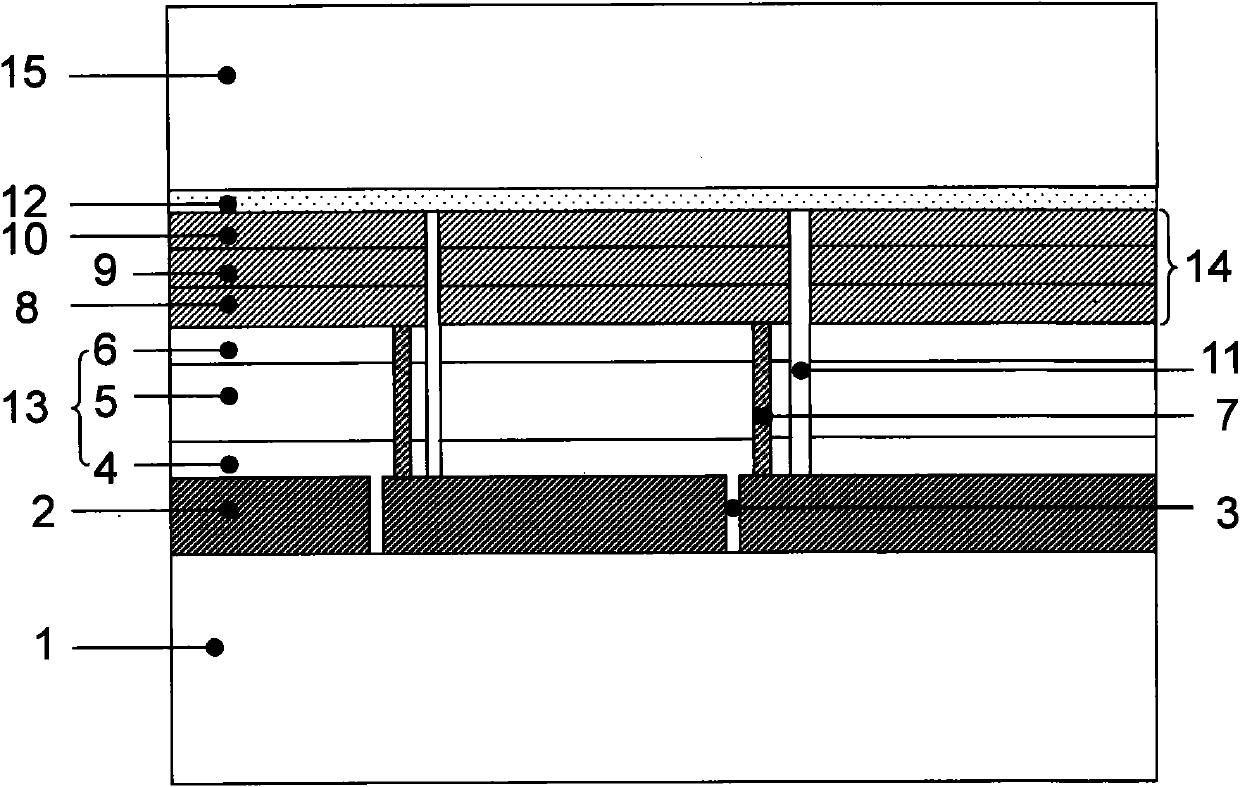

[0014] from figure 1 It can be seen from the given examples that the light-transmissive thin-film solar cell module produced by the method of the present invention includes a transparent substrate 1, a first electrode layer 2, a photoelectric conversion cell region 13 and a back electrode layer 14, wherein the first The electrode layer 2 is disposed on the transparent substrate 1, the photoelectric conversion cell area 13 is disposed above the first electrode layer 2, the back electrode layer 14 is disposed above the photoelectric conversion cell area 13, and the three grooves 3, 7, and 11 are all in the Y direction and are parallel to each other;

[0015] The groove 3 separates the first electrode layer 2, has an opening on the interface between the first electrode layer 2 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com