Method for manufacturing optical flat plate with beam converging function

An optical flat panel and a manufacturing method technology, applied in the optical field, can solve the problems of restricting the use and promotion of liquid lenses, being unable to apply high integration, unable to achieve super-resolution, etc., and achieving the effects of remarkable focusing effect, light weight and high integration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

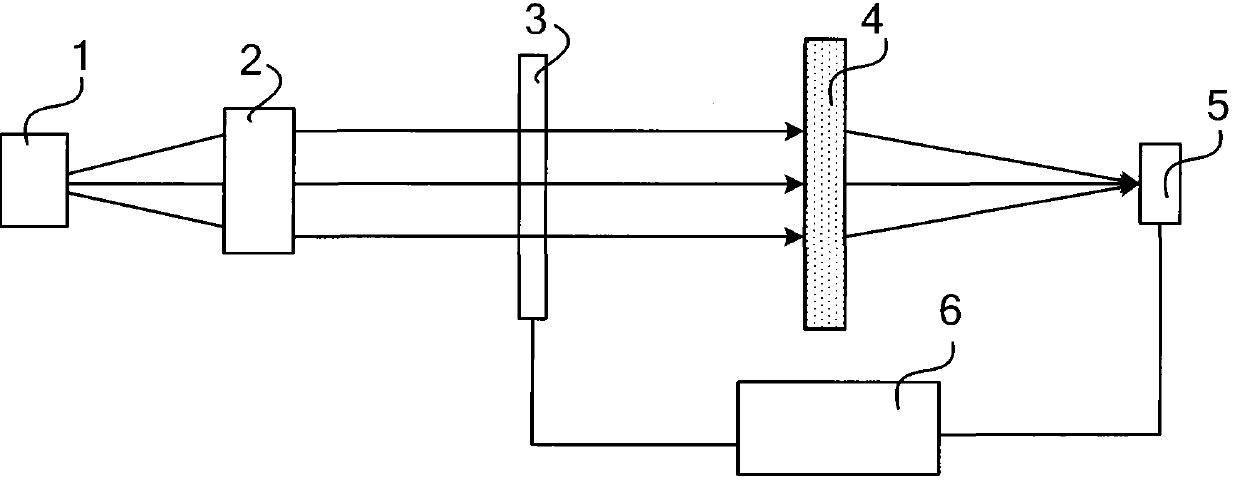

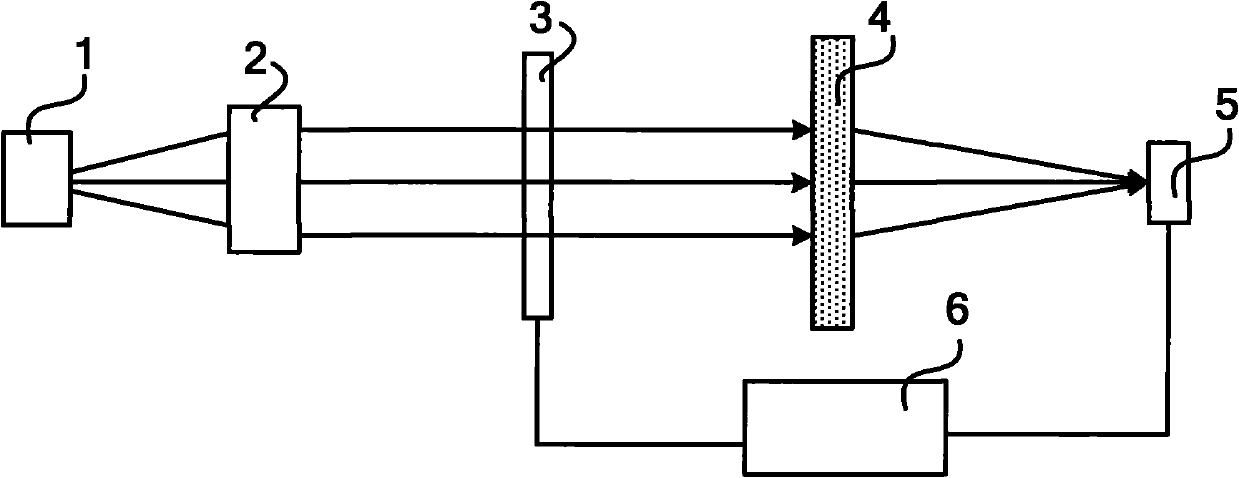

[0013] The present invention will be further described below in conjunction with drawings and embodiments.

[0014] Usually, in multi-level scattering layers such as white pigments, biological tissues, and paper, the spatial fluctuation of the refractive index causes multi-level scattering of light, causing the beam to diverge and cannot be focused. The light beam emitted by the light source passes through the beam expander and collimator, and then passes through the multi-level scattering layer. Due to the multi-level scattering of light in the multi-level scattering layer, the outgoing beam diverges, and no special phenomenon can occur. In classical imaging systems, the multilevel scattering that occurs when the beam passes through the multilevel scattering layer is an unfavorable factor because it reduces the resolving power of the system. The invention utilizes beam wavefront phase adjustment technology, and couples the wavefront phase with multi-level scattering, optimize...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com