Technical scheme for shortening flow of rotor spinning

A technical solution, the technology of air spinning, which is applied in the field of technical solutions for shortening the process of air spinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

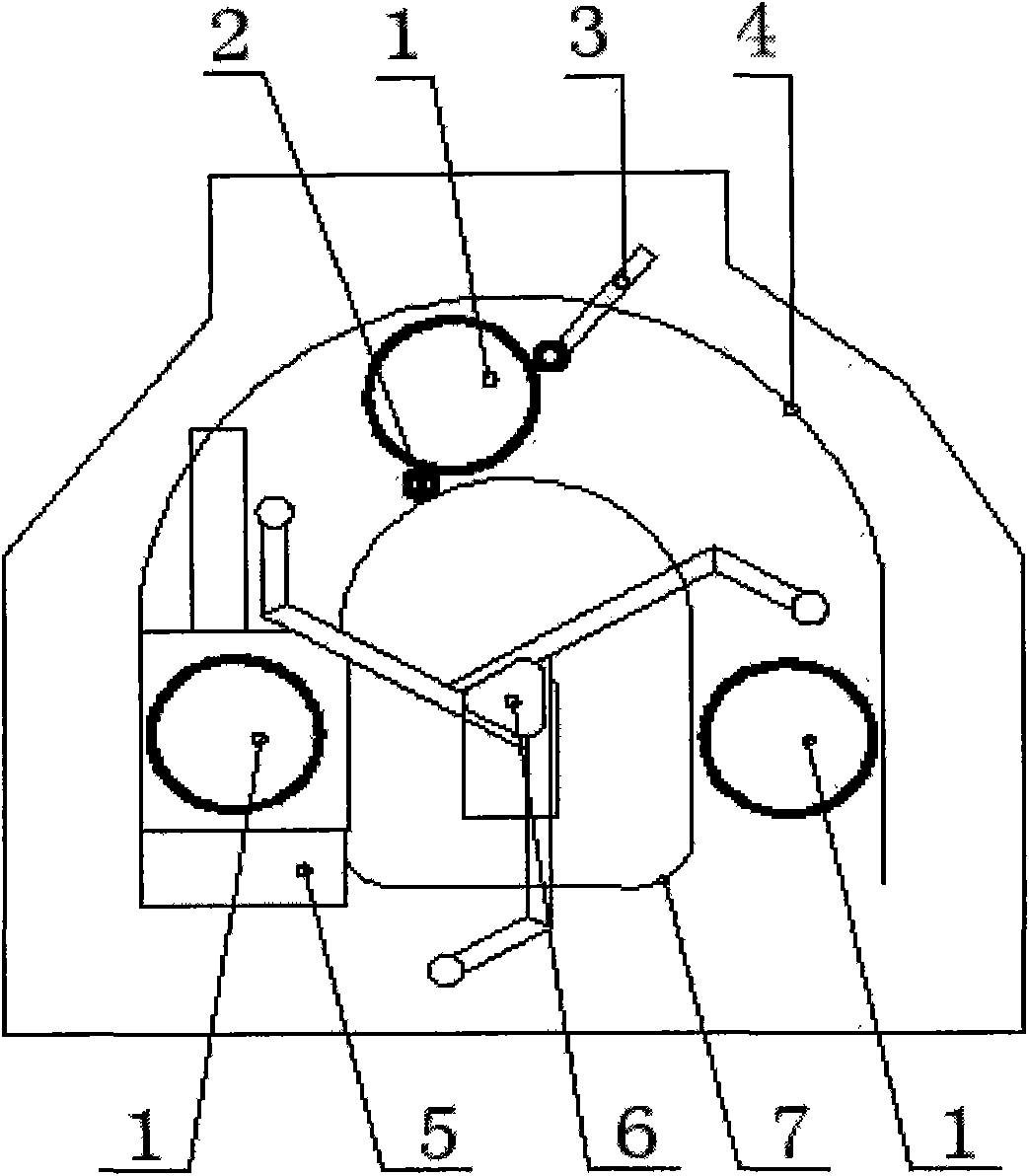

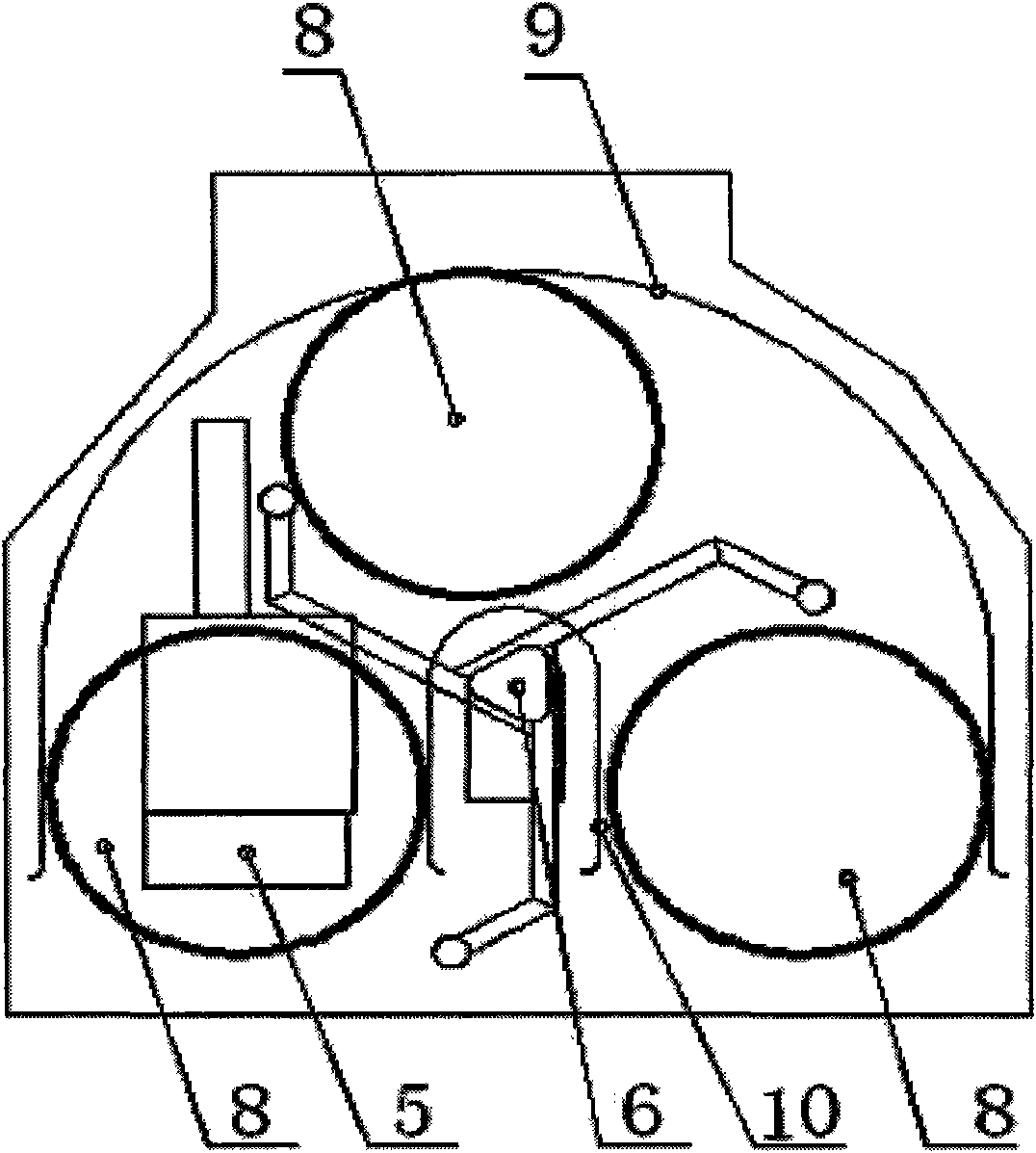

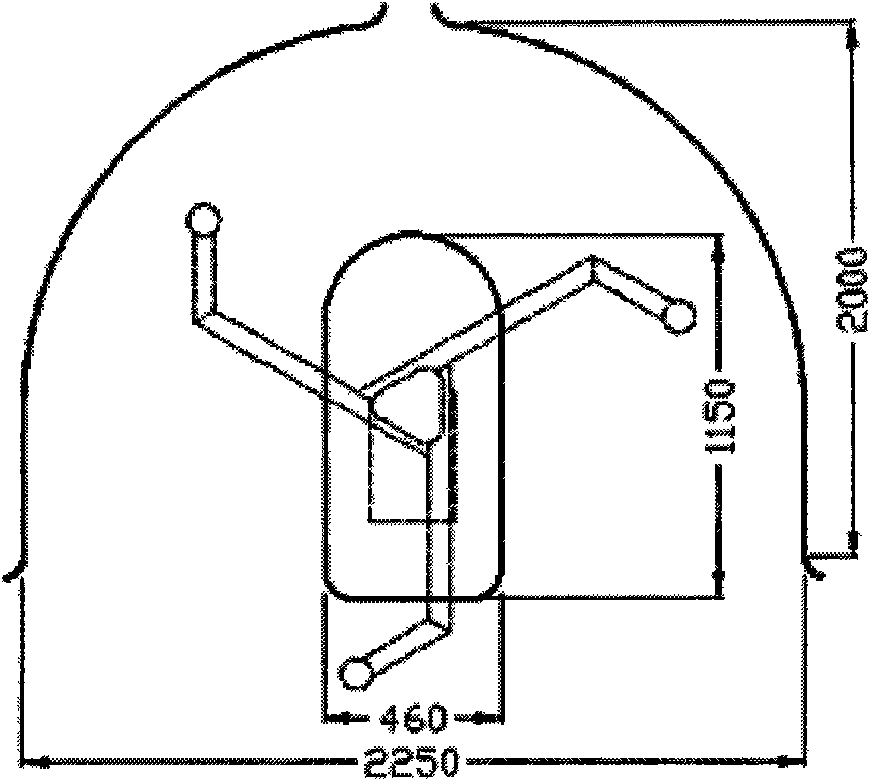

[0009] The specific embodiment of the present invention is briefly described below in conjunction with accompanying drawing: the process flow scheme of reducing the draw frame process is relatively simple, and the production enterprise can directly shut down or dismantle the draw frame equipment, and directly supply the carded sliver to the air spinning machine. Previously, it was necessary to change the large barrel package of the carding machine into a small barrel package. The method was to change the large barrel outer retaining ring 9 into a small barrel outer retaining ring 4, and change the large barrel inner retaining ring 10 into a small barrel The inner retaining ring 7 and the keg automatic keg changing device increase the front positioning wheel 2 and the limit arm 3 to ensure the stability of the keg production process. The size and shape of the inner retaining ring and the outer retaining ring of the sliver barrel are determined according to the diameter of the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com