The feeding mechanism of the automatic filter rod boxing machine

A cartoning machine and feeding machine technology, applied in the directions of packaging, transportation and packaging, single objects, etc., can solve the problem that the pallet structure is not described in detail, and achieve the effect of improving the filling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

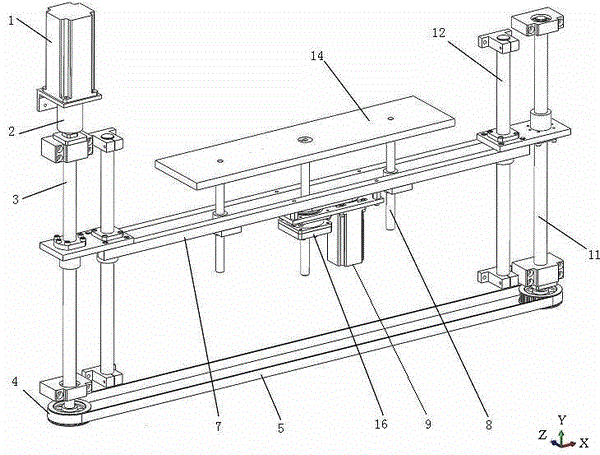

[0029] The feeding machine of the automatic filter rod boxing machine as shown in the figure has a feeding bin, a sieve needle, and two vertical columns. A support plate assembly is set between the two vertical columns, and there is a vertical side baffle between the two vertical columns and close to the inner side of the vertical column. The two side baffles and the support plate assembly form the upper Rod storage bin when feeding.

[0030] The pallet assembly has servo motor A1, servo motor B9, two ball screws 3 and 11, two linear optical axes 12, two timing pulleys 4, timing belt 5, pallet bracket 7, pallet drive structure, Supporting plate 14, supporting plate guide shaft 8.

[0031] The servo motor A1 is connected to the upper end of the ball screw A3 through the coupling 2, the lower end of the ball screw A3 is connected to a synchronous pulley 4, the lower end of the ball screw B11 is connected to another synchronous pulley 4, and the connection between the two synchr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com