A kind of equal-volume cartoning transfer mechanism for food packaging machinery

A food packaging and machinery technology, applied in the field of mass-packing and transfer mechanism, can solve the problems of large occupied space, low packaging efficiency, complex structure, etc., and achieve the effect of small occupied space, neat product packaging and high product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

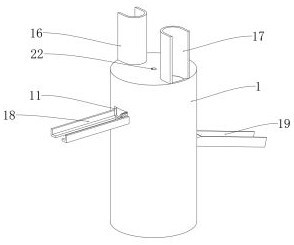

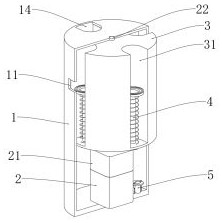

[0022] refer to figure 1 , image 3 , Figure 4 , Figure 7 and Figure 8 , an equal-volume boxing and transporting mechanism for food packaging machinery, comprising a body 1, an air pressure pump 2 is installed on the inner bottom wall of the body 1, a driving motor 21 is installed on the air pressure pump 2, and the shaft of the driving motor 21 is fixedly installed There is a drive shaft 22, the upper end of the drive shaft 22 is rotatably inserted on the top wall of the body 1, a core column 3 is fixedly installed on the drive shaft 22, and four blanking materials passing through the top wall are symmetrically opened on the side wall of the core column 3. Slot 31, each blanking slot 31 is equipped with a gravity quantitative mechanism 4, a magnetic trigger mechanism 5 is installed on the inner bottom wall of the body 1, a pump pressure pipe 23 is installed on the air pump 2, and the pump pressure pipe 23 is far away from the air pressure pump One end of the 2 extends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com