Preparation method of jute viscose

A viscose fiber and alkali cellulose technology is applied in the field of preparation of hemp viscose fiber, which can solve the problems of low strength of hemp viscose fiber and affect the strength of cellulose, so as to achieve short production cycle, increase swelling degree, and reduce content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

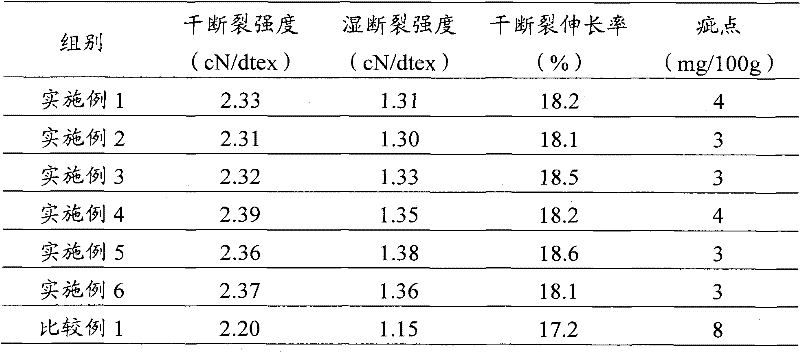

Examples

preparation example Construction

[0017] The invention provides a kind of preparation method of hemp viscose fiber, comprising:

[0018] The hemp pulp is soaked, squeezed and pulverized to obtain alkali cellulose, and the average degree of polymerization of the hemp pulp is 400-450;

[0019] After the alkali cellulose is treated by yellowing, dissolving and filtering, a spinning dope solution is obtained;

[0020] The spinning glue solution is spun to obtain hemp viscose fiber.

[0021] The invention uses the hemp pulp with a lower average degree of polymerization as raw material to produce the hemp viscose fiber, and does not need to go through aging steps to adjust the molecular weight of the hemp pulp, so that the cellulose molecular chain will not be broken sharply, so that the strength of the fiber will not be reduced . According to the present invention, the average degree of polymerization of the hemp pulp is 400-450.

[0022] In order to avoid that hemicellulose has an impact on crystallinity and or...

Embodiment 1

[0033] Put 15kg of hemp pulp with an average degree of polymerization of 450, a cellulose content of 92%, an ash content of 0.14%, an iron content of 20ppm, and a whiteness of 79% into the soaking tank, and soak for 20 minutes at 95°C. Alkali 220g / L is used; the impregnated hemp pulp is squeezed, pulverized and cooled to obtain alkali cellulose; the alkali cellulose is put into a yellowing machine for yellowing, the initial temperature of yellowing is 21°C, and the final temperature is At 28°C, the amount of carbon disulfide is 38% of the hemp pulp. After yellowing for 70 minutes, the obtained material is dissolved, filtered, defoamed, and filtered to obtain a spinning dope; the spinning dope is put into a spinning machine, According to the ratio of sulfuric acid 120g / L, sodium sulfate 320g / L and zinc sulfate 13g / L, an acid bath is formed to spin the spinning dope solution at 50°C to obtain hemp viscose fiber, and the hemp viscose fiber is Cutting and drying are carried out to...

Embodiment 2

[0036] Put 20kg of hemp pulp with an average degree of polymerization of 400, a cellulose content of 91%, an ash content of 0.10%, an iron content of 23ppm, and a whiteness of 79% into the soaking tank, and soak for 30 minutes at 75°C. Alkali 260g / L is used; the impregnated hemp pulp is squeezed, pulverized and cooled to obtain alkali cellulose; the alkali cellulose is put into a yellowing machine for yellowing, the initial temperature of yellowing is 21°C, and the final temperature is At 28°C, the amount of carbon disulfide is 38% of the hemp pulp. After yellowing for 70 minutes, the obtained material is dissolved, filtered, defoamed, and filtered to obtain a spinning dope; the spinning dope is put into a spinning machine, According to the ratio of sulfuric acid 120g / L, sodium sulfate 320g / L and zinc sulfate 13g / L, an acid bath is formed to spin the spinning dope solution at 50°C to obtain hemp viscose fiber, and the hemp viscose fiber is Cutting and drying are carried out to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com