Catalyst component for olefin polymerization and preparation method thereof

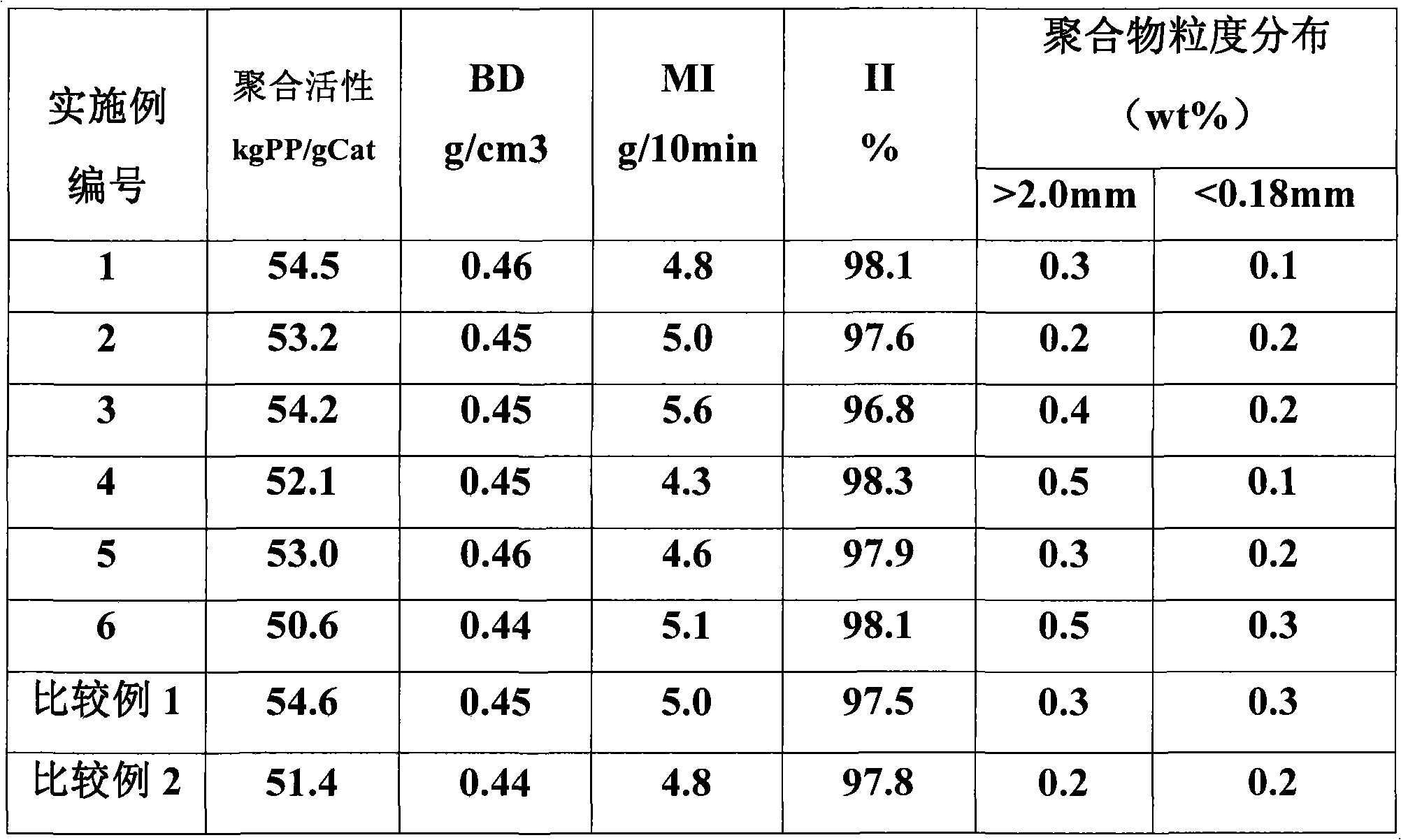

A technology of olefin polymerization and catalyst, which is applied in the field of catalyst components and its preparation, can solve the problems of complex post-treatment process, large amount of solvent recovery, harsh reaction conditions, etc., and achieve good polymer particle shape, good polymerization performance, and dissolution temperature low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Preparation of magnesium chloride complex solution:

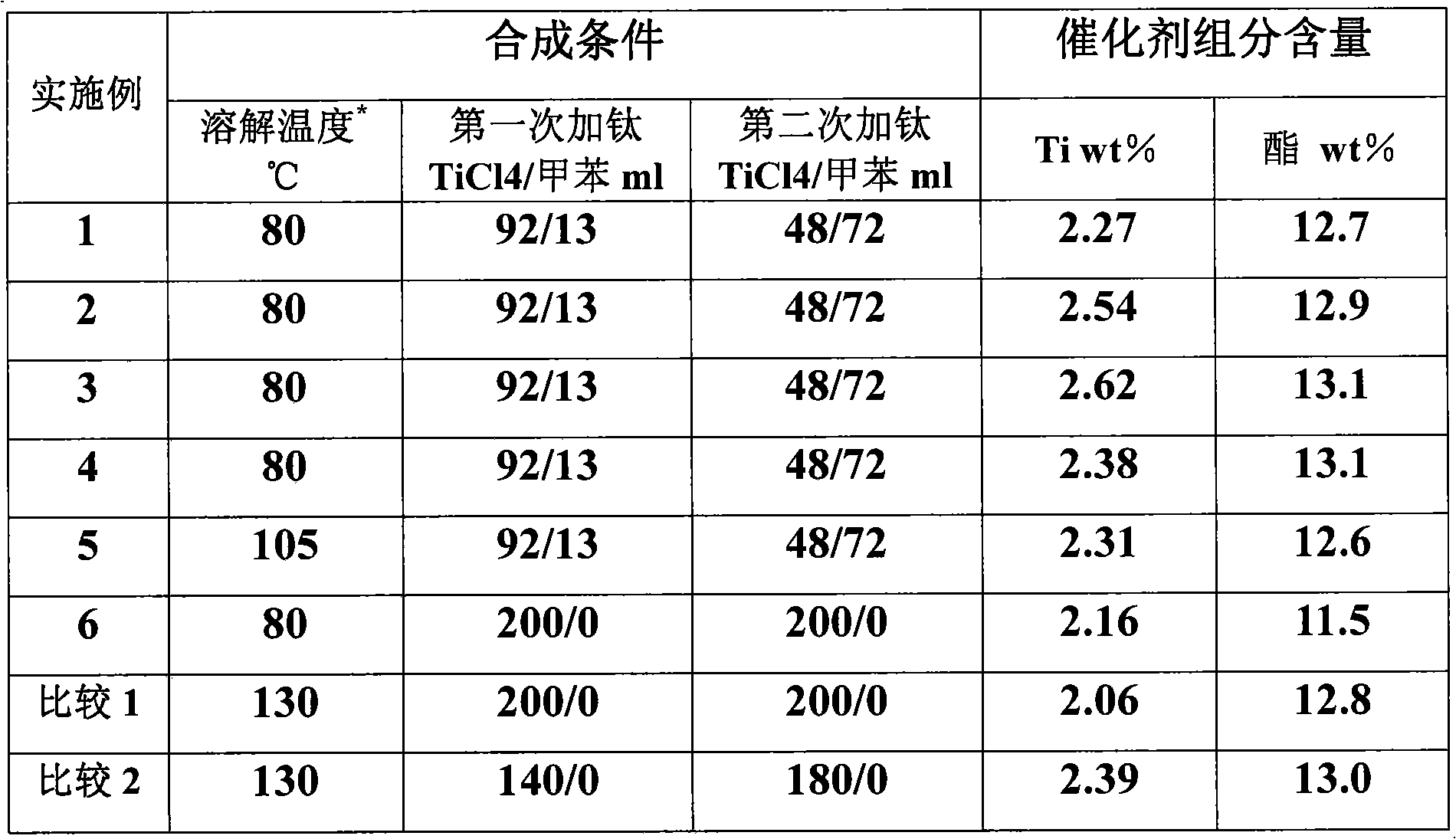

[0039] In the reaction kettle that has been repeatedly replaced by high-purity nitrogen, 5.0g of anhydrous magnesium chloride, 25ml of toluene, 20ml of 2-ethylhexanol, and 1.75ml of n-butanol were added in sequence. React for 2.0 hours, then add 1.2ml ethyl benzoate and 0.6ml diethyl phthalate ester , continue to react for one hour, and cool to room temperature to obtain a stable and uniform magnesium chloride complex solution.

[0040] (2) Preparation of solid titanium catalyst component:

[0041] Add the above-prepared magnesium chloride complex solution into a reactor fully replaced by nitrogen and equipped with 92ml of titanium tetrachloride and 13ml of toluene at -20°C, and stir them to make them fully contact at low temperature. After 4 hours, heat up To 110°C, add 1.2ml of diisobutyl phthalate, and react for 1 hour. After the reaction, filter out the liquid, then add 72ml of toluene and 48ml of titaniu...

Embodiment 2

[0043] (1) Preparation of magnesium chloride complex solution:

[0044] Change the add-on of ethyl benzoate and diethyl phthalate into 1.4ml and 0.4ml respectively in embodiment 1, all the other are the same as embodiment 1.

[0045] (2) Preparation of solid titanium catalyst component:

[0046] With embodiment 1.

Embodiment 3

[0048] (1) Preparation of magnesium chloride complex solution:

[0049] The ethyl benzoate add-on in embodiment 1 is changed into 1.6ml, does not add diethyl phthalate, and all the other are the same as embodiment 1.

[0050] (2) Preparation of solid titanium catalyst component:

[0051] With embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com