Process for extracting pleocidin from fermentation liquor of saccharopolyspora spinosa

A technology of Saccharopolyspora spinosa and spinosad, which is applied in the field of spinosad extraction, can solve the problems of difficulty in adapting to large-scale industrial production, high equipment requirements, and long time consumption, and achieve mature equipment development, good product quality, and low labor costs. low intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

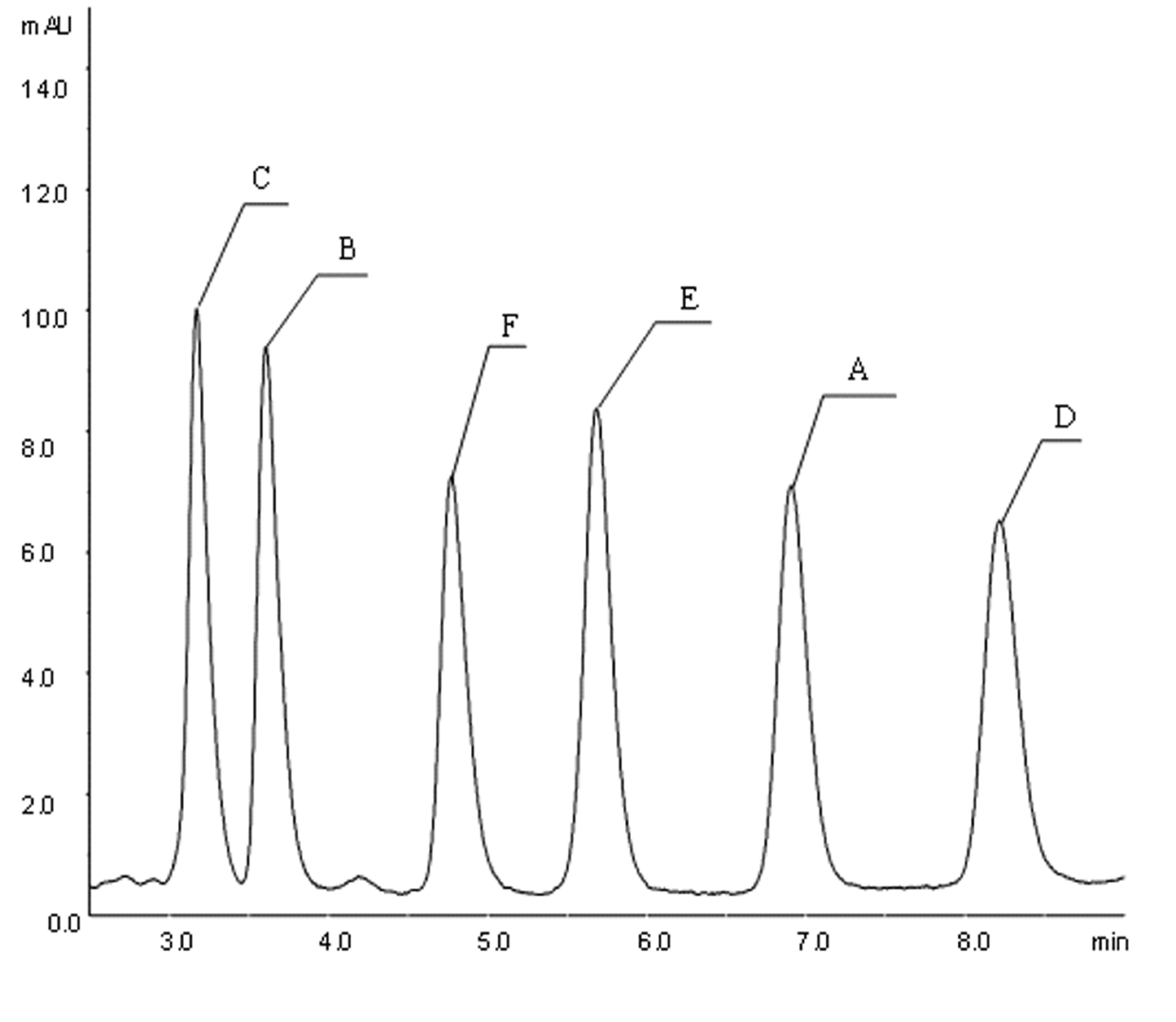

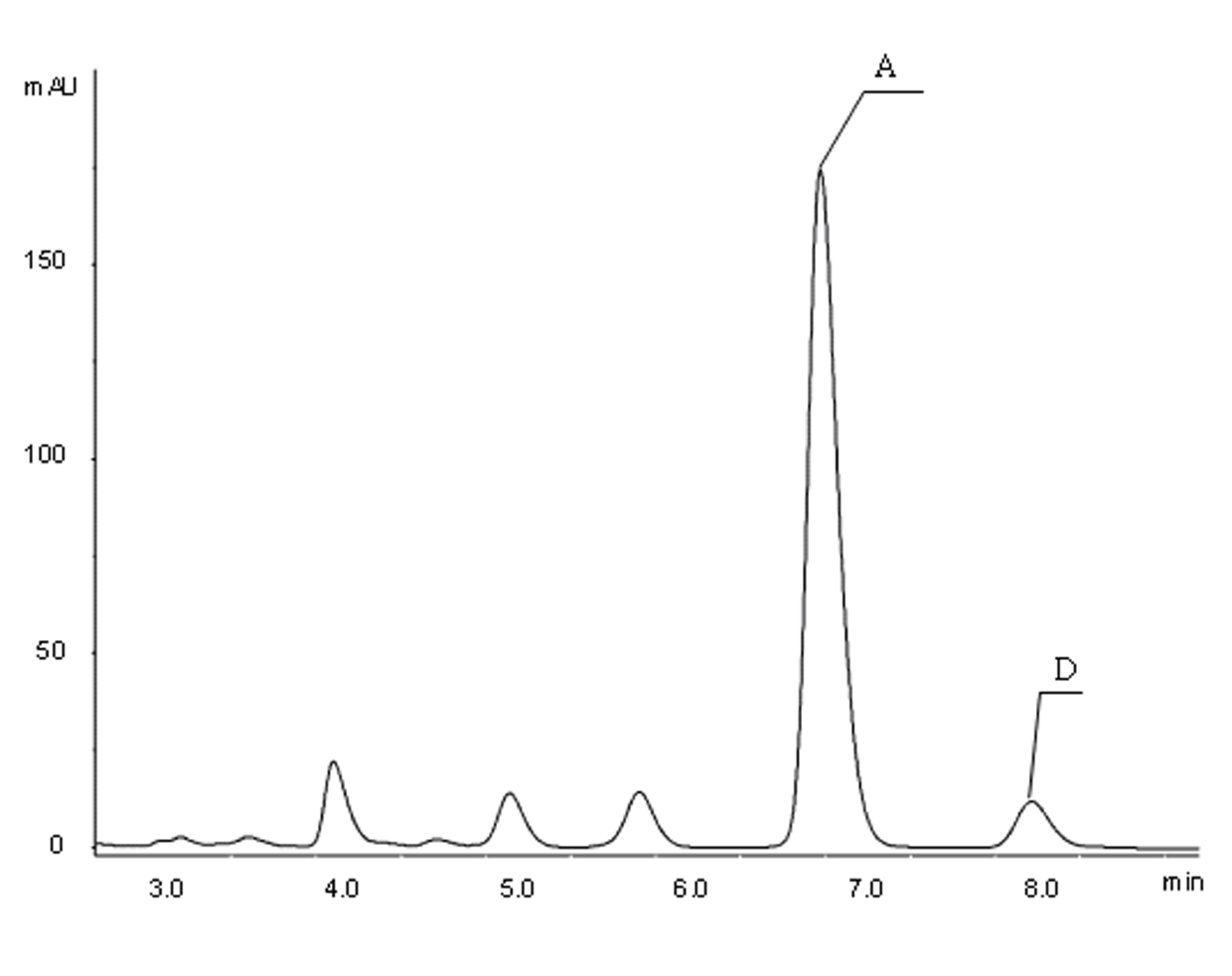

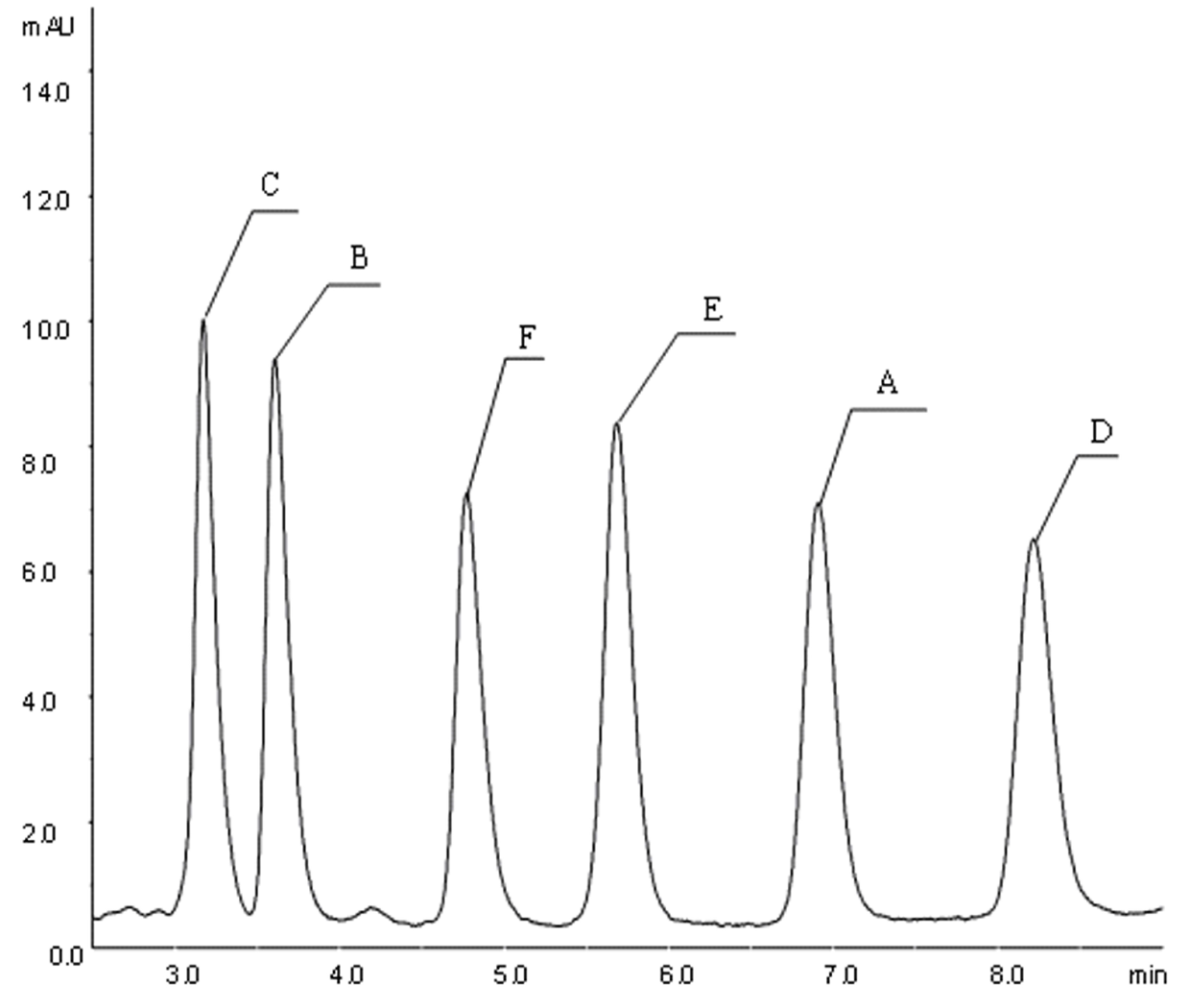

Image

Examples

Embodiment 1

[0022] (1) Add 5 mol / L NaOH solution to the fermentation broth in the fermenter to adjust the pH of the fermentation broth to 9.5, then heat the fermentation broth to 60°C, heat and stir for 35 minutes; (2) After cooling the fermentation broth to room temperature Add methanol, the volume ratio of fermentation broth to methanol is 1:1.5, stir and extract at 30°C for 8 hours, discharge the material to a plate and frame filter press, filter and collect the filtrate to obtain the extract clear liquid; (3) extract clear The liquid was transferred to a rotary evaporator for vacuum concentration and volatilization to completely remove methanol to obtain a spinosad concentrated solution with a yield of 98.3%; (4) add butyl acetate to the spinosad concentrated solution for extraction, and the extraction conditions were: two-phase volume ratio ( Extraction solvent / spinosyn concentrated solution) = 1:1, the temperature is room temperature 25°C, pH = 9.0, and the extraction time is 10 min;...

Embodiment 2

[0024](1) Add 3 mol / L NaOH solution to the fermentation broth in the fermenter, adjust the pH of the fermentation broth to 10.5, heat the fermentation broth to 65°C, and heat and stir for 45 minutes; (2) After cooling the fermentation broth to room temperature Add methanol, the volume ratio of fermentation broth to methanol is 1:1, stir and extract at 30°C for 12 hours, then discharge the material to a plate and frame filter press, filter and collect the filtrate to obtain the extract clear liquid; (3) extract The supernatant liquid was transferred to a vacuum concentration tank to volatilize and remove methanol to obtain a spinosad concentrated solution with a yield of 98.4%; (4) Add butyl acetate to extract the spinosad concentrated solution, using a CTL70-N centrifugal extractor with a drum diameter of 70 mm, rotation speed 2500 r / min, extraction conditions: volume ratio of two phases (extraction solvent / spinosyn concentrate) = 1:1, temperature 30°C, pH = 8.5; (5) The CTL70...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com