Method for preparing linear alpha-olefin

An olefin and linear technology, which is applied in the field of preparing linear α-olefins, can solve the problems of narrow distribution range of α-olefin products, increased investment cost and operating cost of production equipment, and inability to flexibly adjust content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

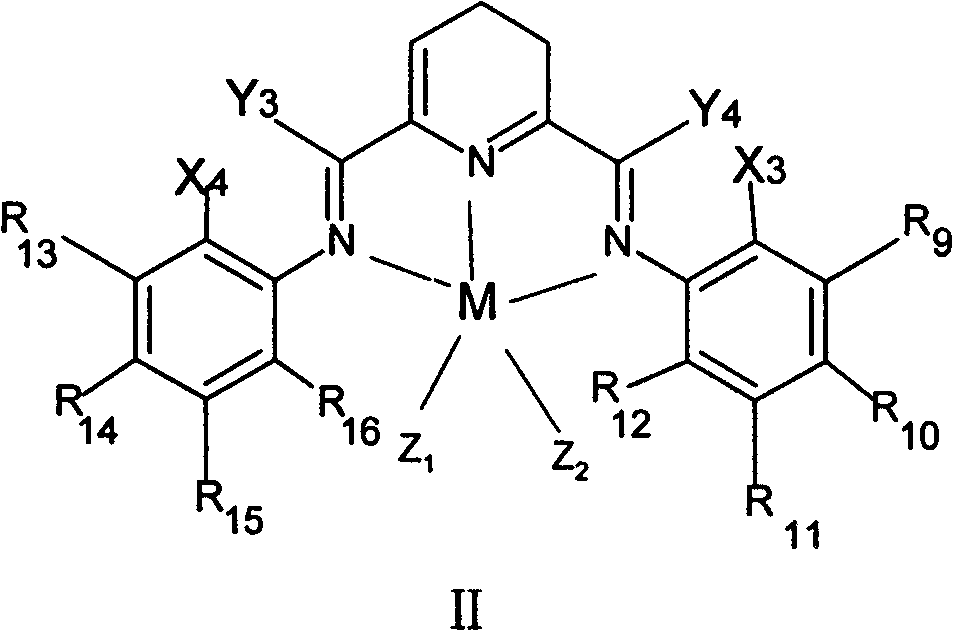

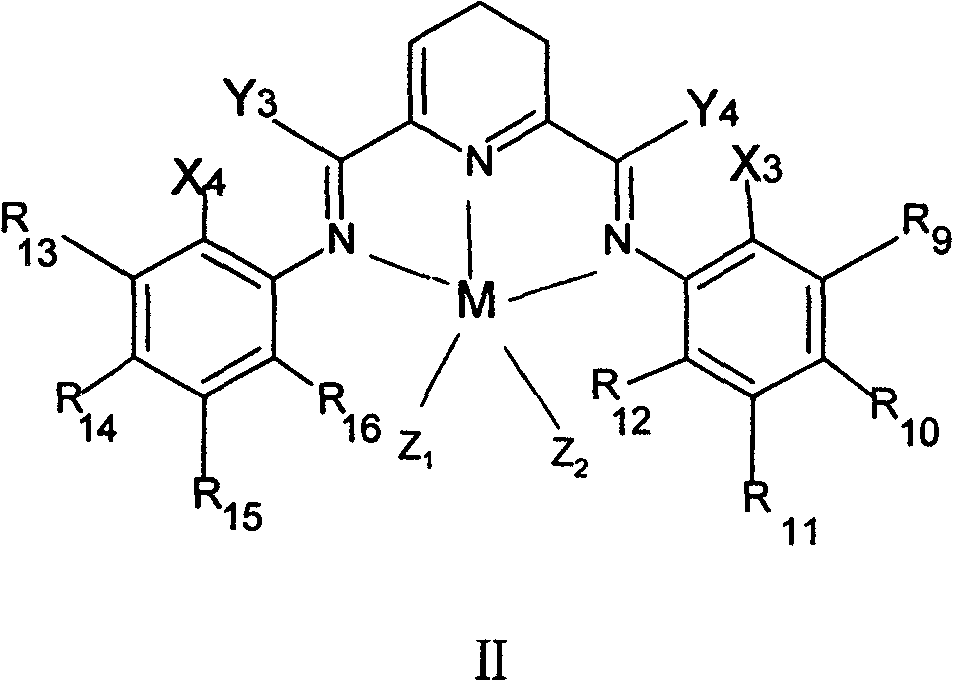

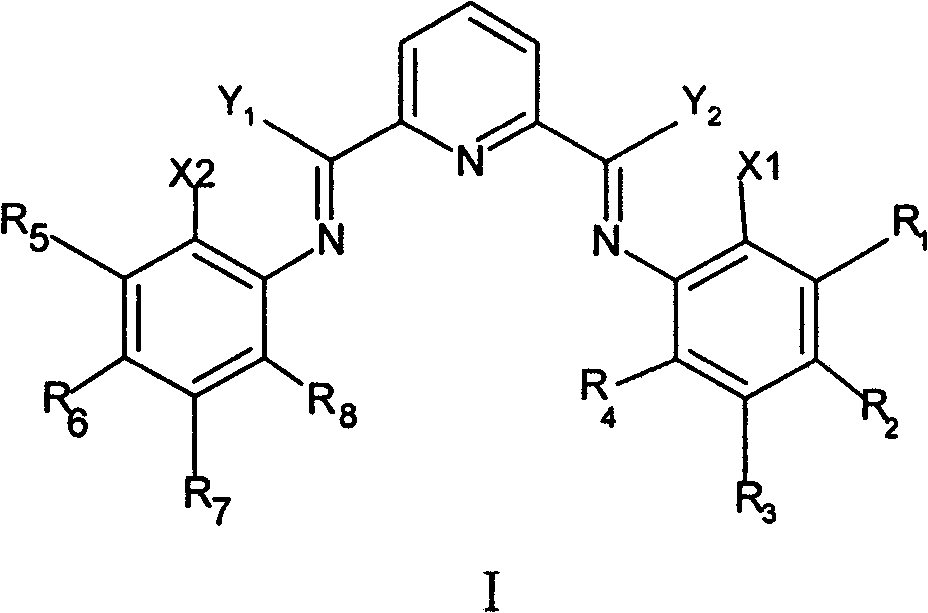

Method used

Image

Examples

Embodiment 1

[0051] In a 50ml flask, add 4.5g 2-methyl-4-methoxyaniline, 1.63g 2,6-diacetylpyridine, 20ml toluene, 3g molecular sieve and 0.5g silica-alumina catalyst, after reacting for 18 hours, filter , and washed with 20ml of toluene, the solvent was removed under reduced pressure, and the product was recrystallized in methanol to obtain light yellow ligand L1{2,6-bis-[(2-methyl-4-methoxyanilinoethyl)pyridine] }, yield 80%.

[0052] 1 H-NMR (CDCl 3 / TMS, δ): 8.26 (d, 2H), 8.02 (t, 1H), 6.99 (d, 4H), 6.72 (m, 2H), 3.79 (s, 6H), 2.34 (s, 6H). Elemental analysis: calculated value (mass percentage, %) C: 74.80, H: 6.73, N: 10.47, O: 7.98; measured value (mass percentage, %) C: 74.23, H: 7.03, N: 10.08, O: 8.64 .

Embodiment 2

[0054] In a 50ml flask, add 4.2g 2-chloro-4-methylaniline, 1.63g 2,6-diacetylpyridine, 20ml toluene, 3g molecular sieve and 0.5g silica-alumina catalyst, after reacting for 24 hours, filter, and use 20ml of toluene was washed, the solvent was removed under reduced pressure, and the product was recrystallized in methanol to obtain light yellow ligand L 2 {2,6-Di-[(2-chloro-4-methylanilinoethyl)pyridine]}, yield 82%.

[0055] 1 H-NMR (CDCl 3 / TMS, δ): 8.23 (d, 2H), 7.99 (t, 1H), 7.07 (s, 2H), 6.88 (d, 2H), 6.69 (d, 2H), 2.80 (s, 6H), 2.22 ( s, 6H). Elemental analysis: calculated value (mass percentage, %) C: 67.33, H: 5.16, N: 10.24, Cl: 17.27; measured value (mass percentage, %) C: 66.81, H: 5.36, N: 9.77, Cl: 18.06 .

Embodiment 3

[0057] In a 50ml flask, add 1.5g 2,6-diacetylpyridine, 5.2g 2,6 difluoroaniline, 20ml toluene, 3g molecular sieve and 0.5g silica aluminum catalyst, after reacting for 12 hours, filter, and wash with 20ml toluene, The solvent was removed under reduced pressure, and the product was recrystallized in methanol to give light yellow ligand L 3 {2,6-Di-[(2,6-difluoroanilinoethyl)pyridine]}, yield 78%.

[0058] 1 H-NMR (CDCl 3 ): δ=8.47 (d, 2H), 7.93 (t, 1H), 7.07 (t, 4H), 6.99 (d, 2H), 2.46 (s, 6H,). Elemental analysis: calculated value (mass percentage, % ): C, 65.45; H, 3.92; N, 10.90; Measured value (mass percentage, %): C, 65.61; H, 4.02; N, 10.78.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com