Processing method for wash-free millet

A processing method, the technology of millet, applied in the direction of grain processing, application, grain pod removal, etc., can solve the problems of not meeting the requirements of scouring, inability to remove micro dust, decomposition of nutrients, etc., and achieve reduction of broken rice and filling technology And market blank, improve the effect of whole rice rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Raw grain selection: Design and use a 150T millet production line per day, choose high-quality millet that meets GB8232-1987 in Zhuluke Town, Jianping, Liaoning, such as the golden seedling variety, and process 150T.

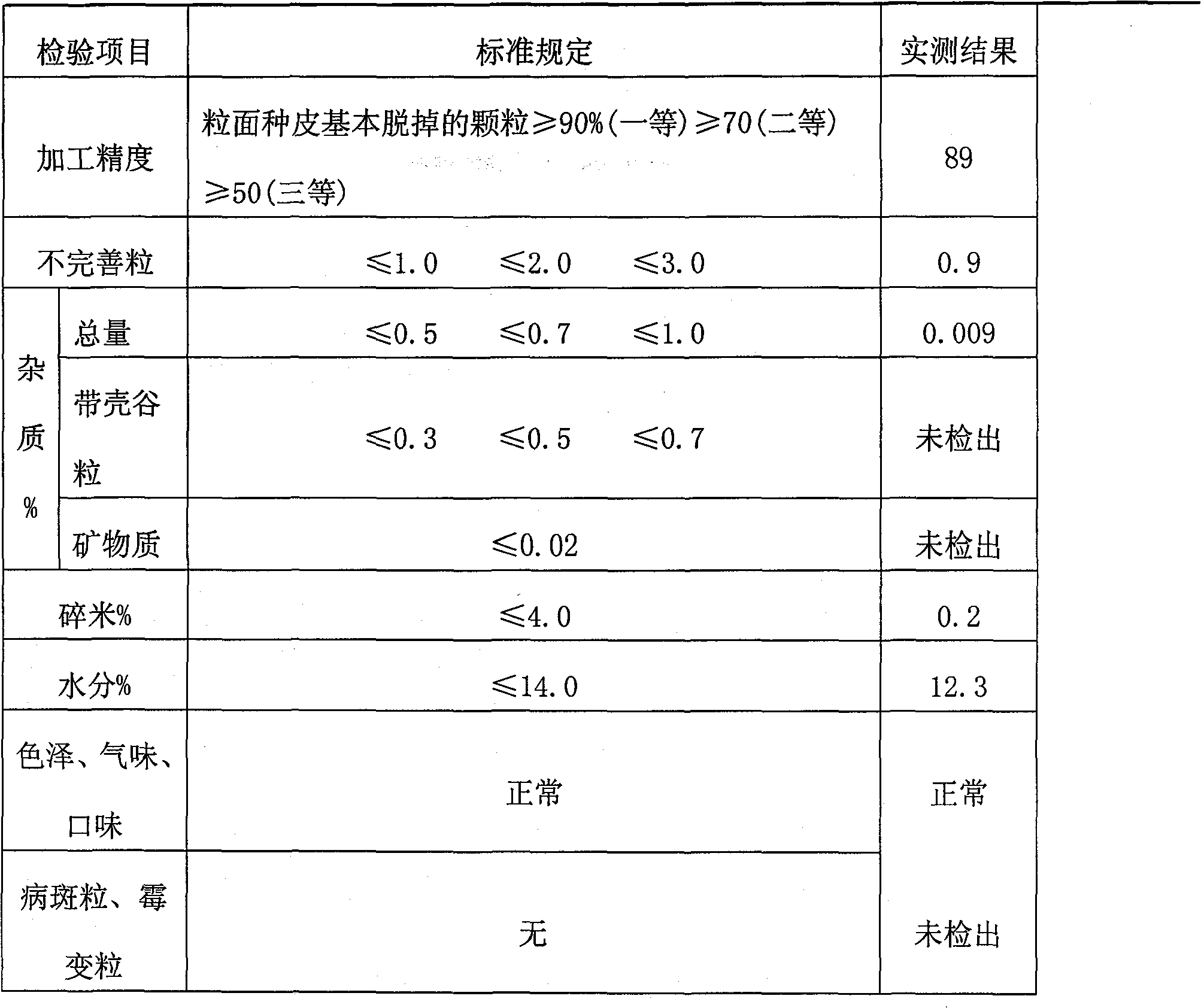

[0011] Inspection standard: GB / T11766-1989, implement GB2715-1981 food hygiene standard, without adding any additives, and the shelf life of vacuum packaging is 12 months.

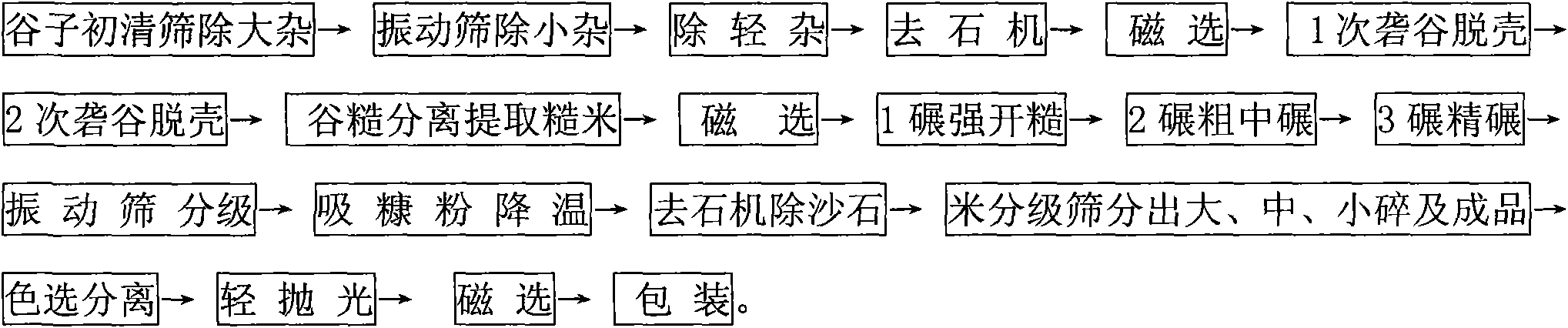

[0012] Processing technology: initial cleaning screen (remove large impurities) → vibrating screen (remove small impurities) → remove light impurities (vertical suction air duct) → stone remover (remove side-by-side stones) → magnetic separation (remove magnetic metal objects) → 1 time of hulling (remove 40% to 50% of the husk) → 2 times of hulling (to make the husk rate reach more than 95%) → separation of rice and paddy (separate the hulled brown rice and put it into the mill, return the hulled rice and return it again) Hulling, return to the original sieve rice and separate again) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com