Solar heat pipe garbage drying equipment

A technology of solar heat pipe and drying equipment, which is applied in the field of solar energy utilization, and can solve problems such as limiting solar drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

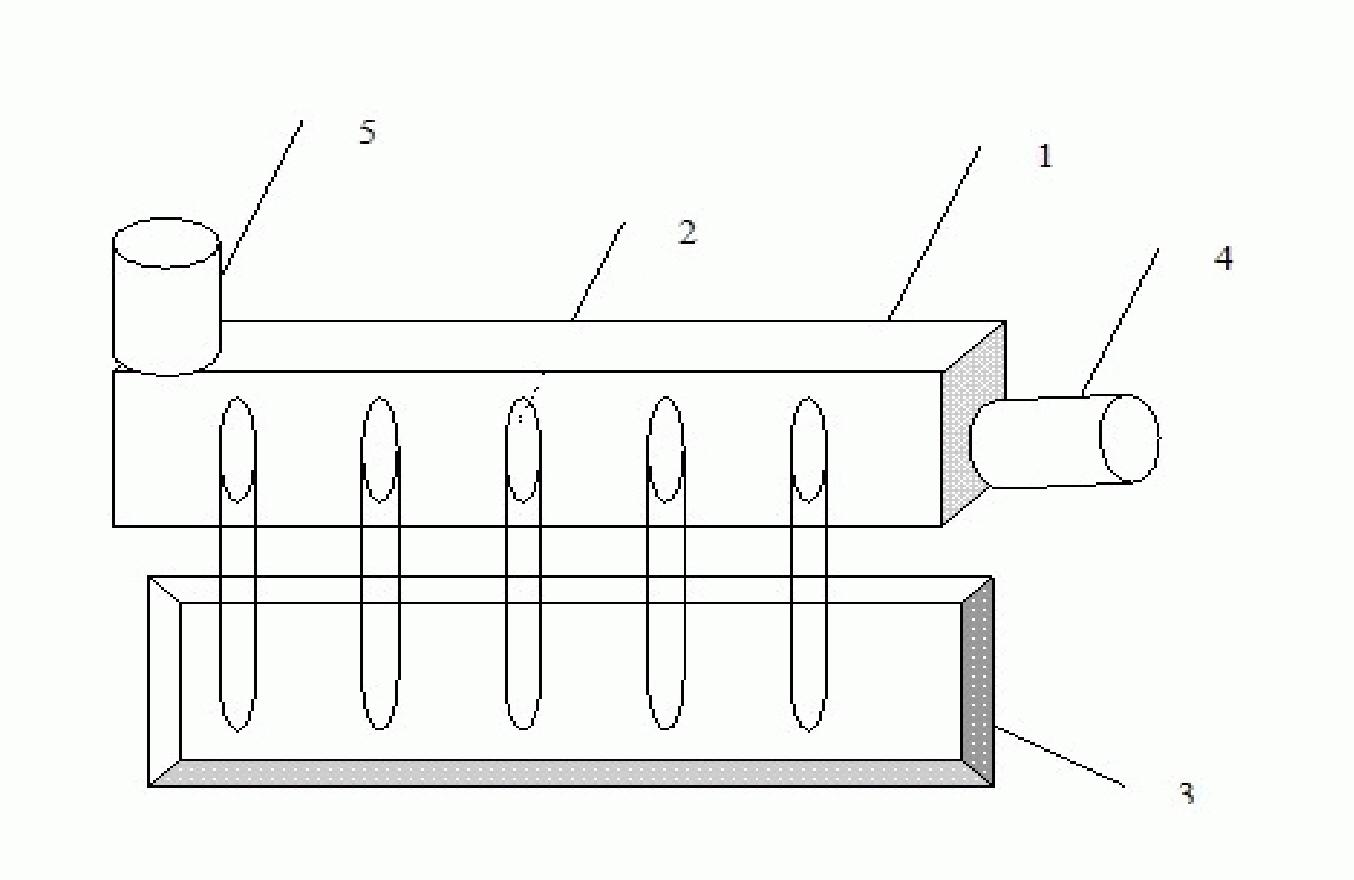

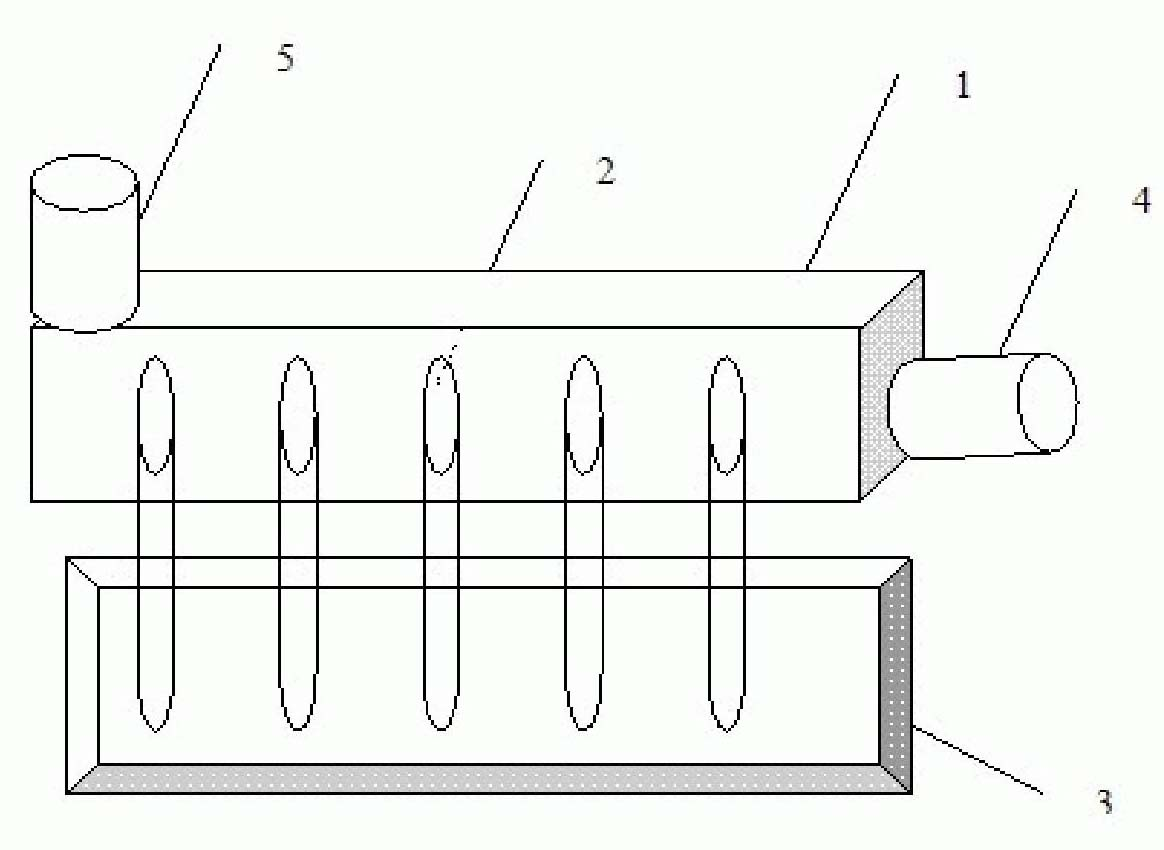

[0037] Embodiment 1: Vacuum tube heat pipe solar energy collection garbage drying system

[0038] like Figure 1 As shown, the solar collection adopts a vacuum tube system, and a plurality of heat pipes are arranged inside it. The evaporation end of the heat pipe is set in the vacuum tube inside the solar energy collection system, and the condensation end of the heat pipe is set inside the drying chamber. The drying chamber is connected with the solar energy collection system. The system conducts heat directly, and the garbage enters the drying chamber from the inlet and is discharged from the outlet, so as to realize the drying of the garbage.

Embodiment 2

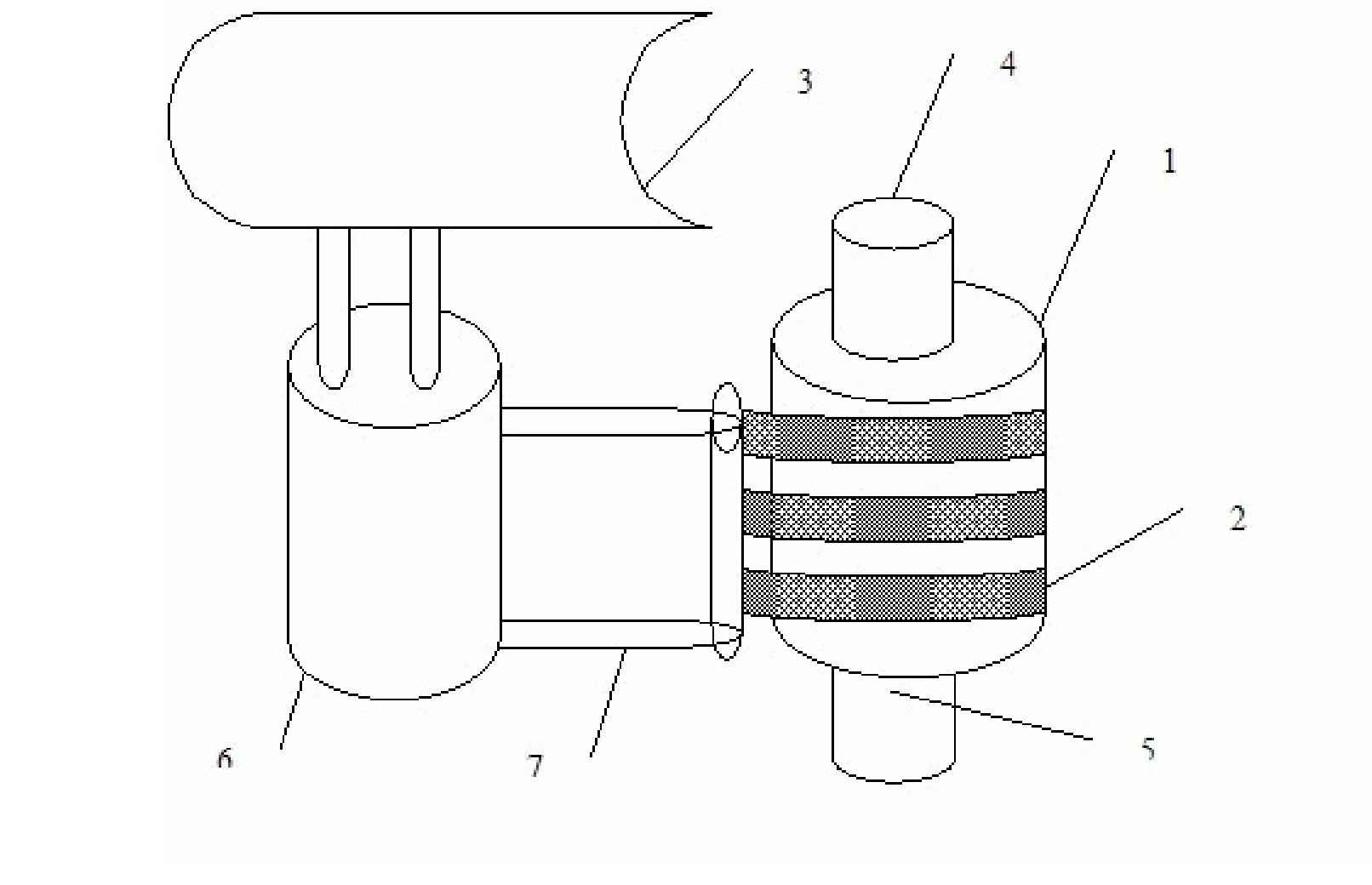

[0039] Embodiment 2: Trough solar collection heat pipe drying system

[0040] like figure 2 As shown, the trough solar thermal utilization system is used to realize the collection of solar energy, and the temperature can be controlled at 300-400 degrees. The trough system exchanges heat energy with the heat accumulator through the fluid circulation system. The two fluid circulation systems realize the connection with the heat pipe in the drying chamber. The heat pipe is arranged inside the drying chamber, and the garbage enters from the entrance and is discharged from the entrance and exit after being dried by the heat pipe in the drying chamber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com