Method for preparing ordered porous aluminum oxide film-transparent conductive glass composite substrate

A technology of transparent conductive glass and porous alumina, which is applied in anodic oxidation, ion implantation plating, coating, etc., can solve the problems that the thickness of the aluminum film cannot reach the micron level, the sputtering conditions are harsh, and stress is generated, and the operation can be achieved. Relaxed environmental requirements, increased preparation repetition rate, and reduced preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Before performing magnetron sputtering on ITO glass, it was cleaned repeatedly with ultrasonic vibration in acetone and isopropanol. After cleaning, it was dried with compressed nitrogen and immediately loaded into the sputtering chamber. The aluminum layer, the tungsten buffer layer and the titanium connection layer were deposited in a DC magnetron sputtering system.

[0025] After putting the ITO substrate into the sputtering chamber, vacuumize the whole system for more than 8 hours, so that the air pressure in the system reaches 10 -7 mbar. The purity of titanium, tungsten and aluminum targets used in sputtering are >99.5%, >99.5%, and 99.999%, respectively. The sputtering powers were 15W, 30W, and 20W; the argon pressures in the sputtering chamber were 3.0Pa, 2.4Pa, and 0.5Pa; the sputtering times were 30 seconds, 30 seconds, and 20 minutes, respectively.

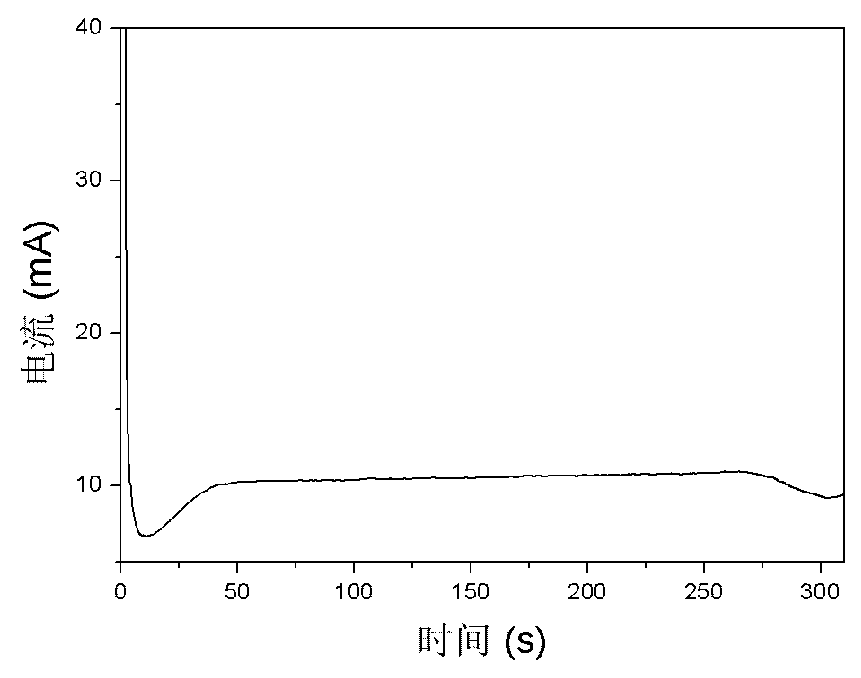

[0026] The sputtered sample was heated to 300°C at a heating rate of 1°C / min, kept at a temperature of 6 hou...

Embodiment 2

[0029] Before performing magnetron sputtering on the FTO glass, it was repeatedly cleaned with ultrasonic vibration in acetone and isopropanol. After cleaning, it was dried with compressed nitrogen and immediately loaded into the sputtering chamber. The aluminum layer, the tungsten buffer layer and the titanium connection layer were deposited in a DC magnetron sputtering system.

[0030] After putting the FTO substrate into the sputtering chamber, vacuumize the whole system for more than 8 hours, so that the air pressure in the system reaches 10 -7 mbar. The purity of titanium, tungsten and aluminum targets used in sputtering are >99.5%, >99.5%, and 99.999%, respectively. The sputtering powers were 15W, 30W, and 20W; the argon pressures in the sputtering chamber were 3.0Pa, 2.4Pa, and 0.5Pa; the sputtering times were 30 seconds, 30 seconds, and 20 minutes, respectively.

[0031] The sputtered sample was heated to 400°C at a heating rate of 1°C / min, kept at a temperature of 6...

Embodiment 3

[0034] Before performing magnetron sputtering on ITO glass, it was repeatedly cleaned by ultrasonic vibration in acetone and isopropanol. After cleaning, it was dried with compressed nitrogen and immediately loaded into the sputtering chamber. The aluminum layer, the tungsten buffer layer and the titanium connection layer were deposited in a DC magnetron sputtering system.

[0035] After putting the ITO substrate into the sputtering chamber, vacuumize the whole system for more than 8 hours, so that the air pressure in the system reaches 10 -7 mbar. The purity of titanium, tungsten and aluminum targets used in sputtering are >99.5%, >99.5%, and 99.999%, respectively. The sputtering power is 15W, 30W, 20W; the argon pressure in the sputtering chamber is 3.0Pa, 2.4Pa, 0.5Pa respectively; the sputtering time is 30 seconds, 30 seconds, 60 minutes respectively.

[0036] The sputtered sample was heated to 350°C at a heating rate of 1°C / min, kept for 6 hours, and then cooled to room...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Hole spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com