Dressing and smelting process of magnetic iron ore with high manganese content, high sulfur content and high alkalinity

A technology of magnetite ore and high alkalinity, applied in blast furnaces, magnetic separation, blast furnace details, etc., can solve problems such as waste of resources, environmental pollution, small particle size of ore powder, etc., and achieve the effect of reducing sulfur content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

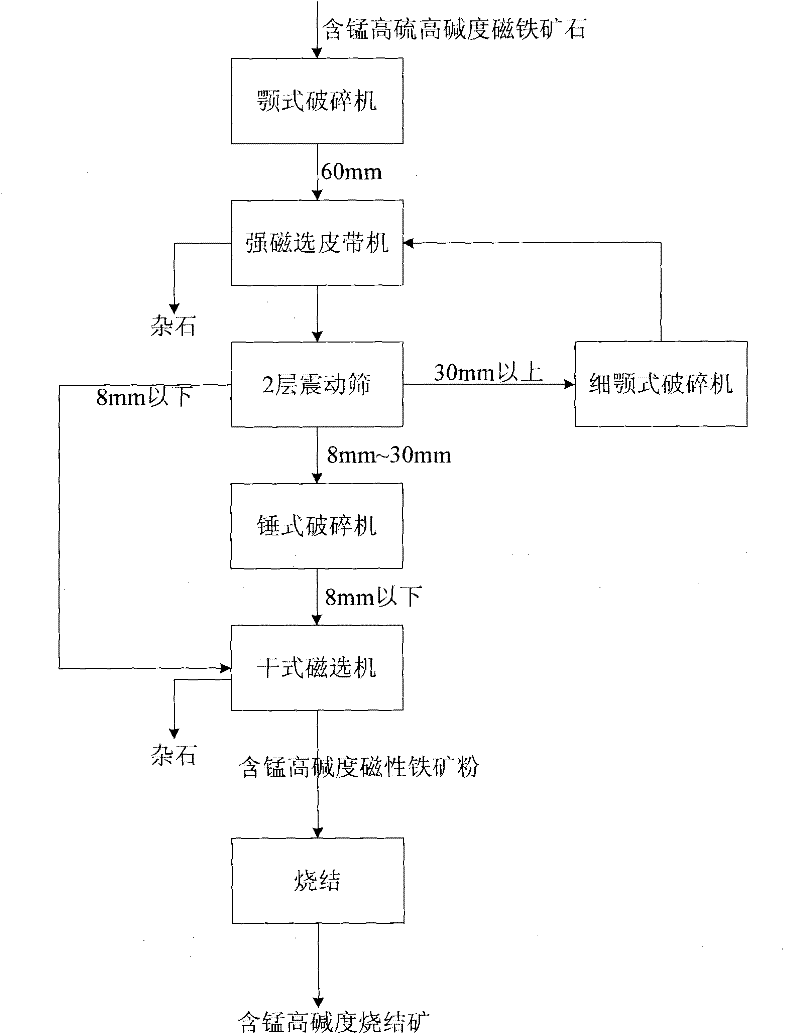

Method used

Image

Examples

Embodiment 1

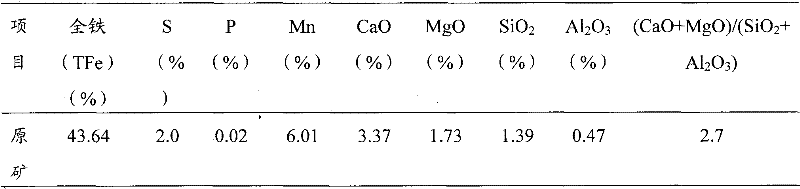

[0063] Taking the deep primary manganese-containing high-sulfur and high-alkalinity magnetite ore in the Liudaogou iron ore area of Linjiang City, Jilin Province as raw ore, the raw ore is analyzed for composition, the results are shown in Table 1, and Table 1 is the composition analysis of the raw ore provided by the embodiment of the present invention result.

[0064] The compositional analysis result of the raw ore that the embodiment of the present invention provides in table 1

[0065]

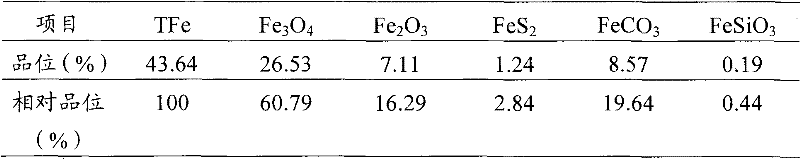

[0066] The phase analysis of the iron element was carried out, and the results are shown in Table 2. Table 2 is the result of the phase analysis of the iron element of the raw ore provided by the embodiment of the present invention.

[0067] The iron element phase analysis result of the raw ore that table 2 the embodiment of the present invention provides

[0068]

[0069] Continuously send the raw ore to a jaw crusher with a specification of 300*750 for coarse crushing, and crus...

Embodiment 2

[0074] Get 0.95 tons of concentrate powder prepared in Example 1 and sinter according to methods well known to those skilled in the art to obtain 0.76 tons of manganese-containing high-alkalinity sintered ore. The composition of the sintered ore is analyzed. The results are shown in Table 4, which is The composition analysis results of the manganese-containing high-basicity sintered ore provided by the examples of the present invention.

[0075] The compositional analysis results of the manganese-containing high-basicity sintered ore provided by the embodiment of the present invention in table 4

[0076]

[0077] Comparing Table 4 with Table 3, it can be seen that after sintering, the grades of iron, manganese and other beneficial elements in the sintered ore have been improved, the basicity has not changed, and the content of sulfur has decreased to 0.05%, indicating that the sintered ore can be used for Smelting iron and steel to produce manganese-containing pig iron or m...

Embodiment 3

[0079] Take 0.76 tons of sinter prepared in Example 2 and carry out blast furnace ironmaking well known to those skilled in the art to obtain 0.48 tons of pig iron and 0.21 tons of manganese-rich slag, wherein the iron content in the pig iron is 90%, and the manganese content in the manganese-rich slag is 29%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com