Manufacturing method of LED device

A technology of LED device and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components and other directions, can solve the problems of reduced resistance of LED lamps, limited illuminated area, large working current, etc., to reduce heat generation, Easy installation and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

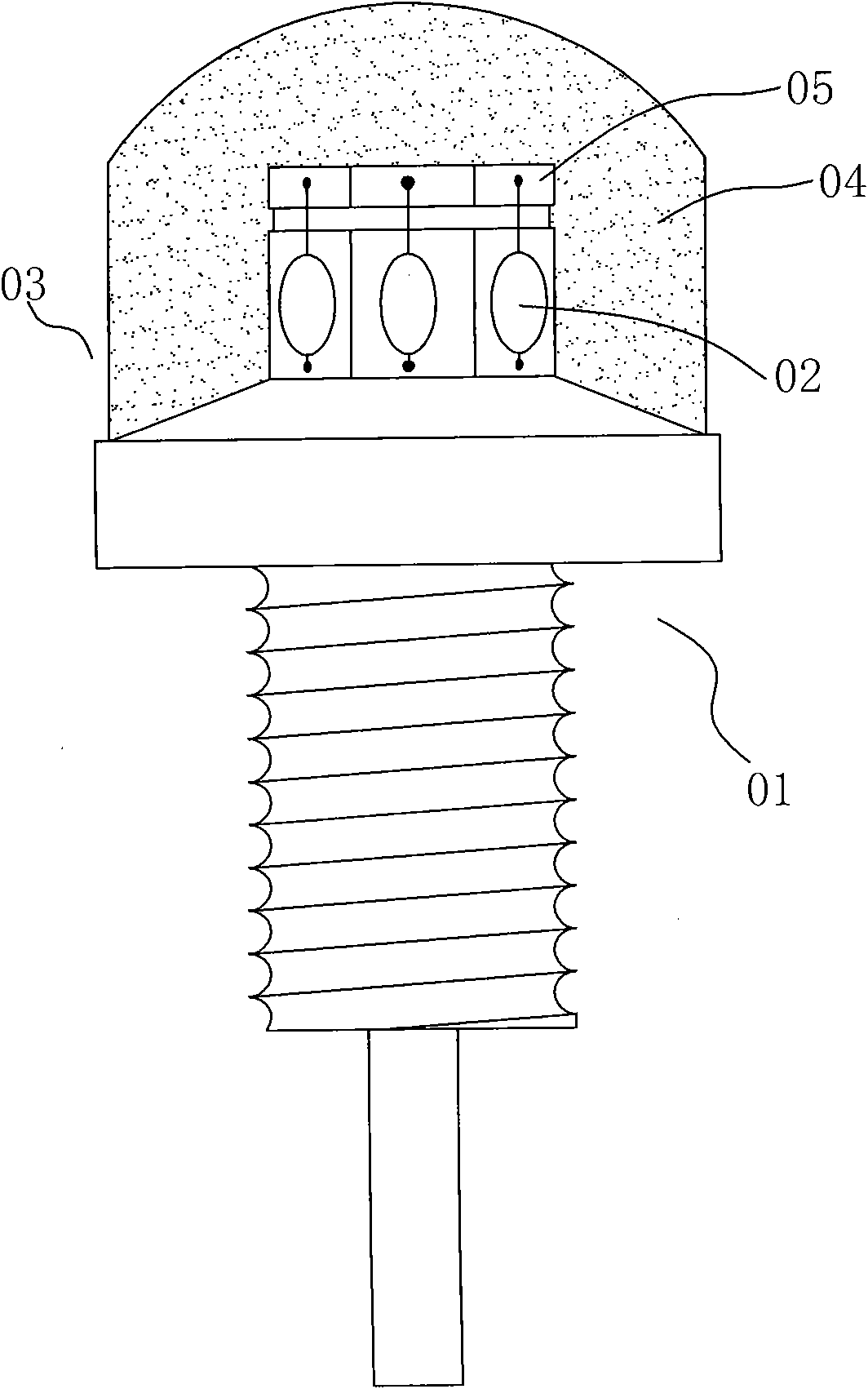

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0035] The production method of this embodiment is as follows:

[0036] 1. Make the bracket 1.

[0037] See Figure 3-7 , the bracket 1 serves as the carrier of the entire LED device, which includes: a main body 11 and probes 12 fixed to the main body 11 and insulated from each other. The main body 11 is composed of the packaging platform 10 and the threaded section 111 , and a through hole is formed in the main body 11 . The main body 11 has a protrusion 100 extending from the top of the packaging platform 10 .

[0038] The above packaging table 10 includes: a boss 101 and a cylinder 102 located at the center of the boss 101 . The above-mentioned protrusion 100 extends from one corner of the top of the cylinder 102 . The cross section of the cylinder 102 is a regular polygon. In this embodiment, the cylinder 102 is a regular tetrahedron, thus realizing 360-deg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com