Method for dyeing acrylic fabric with bacterial dye prodigiosin

A technology of prodigiosin and dyeing method, which is applied in the field of dyeing acrylic fabrics with bacterial dye prodigiosin, can solve the problems of less research and development of dyes, achieve good antibacterial properties, good application prospects, good washing fastness and durability The effect of crocking fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

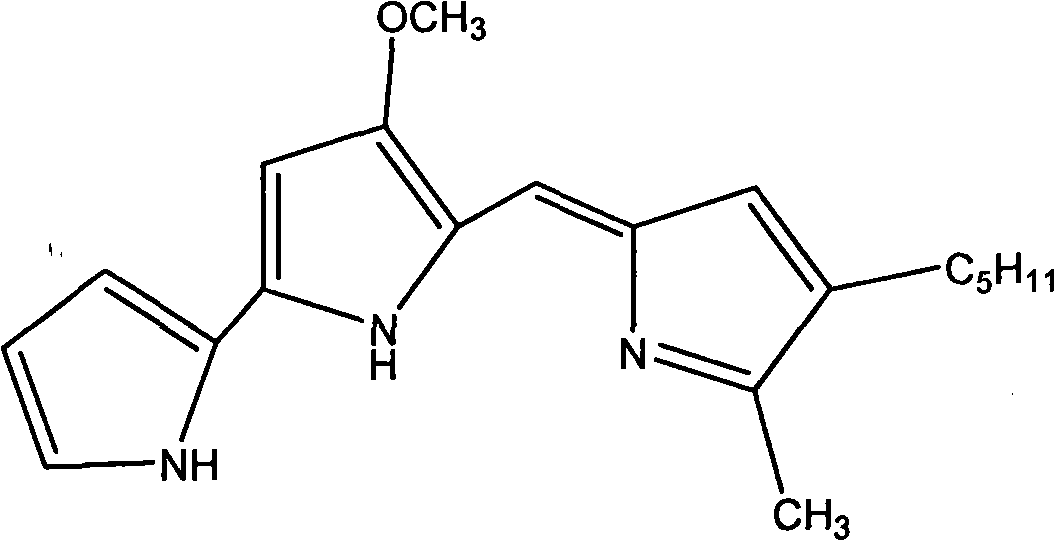

Image

Examples

Embodiment 1

[0020] Preparation of prodigiosin dye

[0021] First, the purchased strains (Serratia marcescens, purchased from the China Medical Bacteria Preservation Management Center) were diluted, and then the diluted bacteria were spread on the plate medium (yeast powder 5g / L, peptone 10g / L , glucose 10g / L, agar powder 20g / L) and cultivated in a constant temperature incubator, pick the strain with red pigment and darker color and spread it on the plate medium, and store the strain at 4°C . The screened bacterial strains were cultured in the seed medium (yeast powder 4.5g / L, peptone 12g / L, NaCl 2.5g / L, KCl 3g / L, glucose 2g / L) for 15h, then inserted into the fermentation medium and cultivated for 30h .

[0022] The supernatant and bacteria were separated separately. The supernatant is directly extracted from the aqueous solution with ethyl acetate, and the flocs are first centrifuged and then concentrated with a rotary evaporator and then extracted in acidic methanol. The method of met...

Embodiment 2

[0024] The acrylic fabric samples will be dyed according to the following processes for testing:

[0025] Process 1: Dye dosage 3% (o.w.f), ethanol: water ratio 1: 2, liquor ratio 1: 40, pH 6.0, dyeing at 95°C for 50 min.

[0026] Process 2: Dye dosage 3% (o.w.f), methanol: water ratio 2: 3, bath ratio 1: 40, pH 4.0, dyeing at 90°C for 50 min.

[0027] According to GB / T 3920-1997 "Textile Color Fastness Test Color Fastness to Rubbing", the rubbing fastness is measured according to the AATCC standard for washing resistance test.

[0028] Finally, the dry rubbing fastness of the acrylic fabric dyed by process 1 is 4 grades, and the wet rubbing fastness is 4-5; the dry rubbing fastness of the fabric after process 2 dyeing is 3-4 grades, and the wet rubbing fastness is 4 -5; the soaping fastness of the dyed fabric is 4-5.

[0029] After the fabric is dyed according to the above process, the antibacterial test of the fabric is carried out according to AATCC standard 100. The res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com