Anticorrosive paint based on modified acrylic resin and preparation method thereof

A technology of acrylic resin and anti-corrosion coatings, applied in anti-corrosion coatings, coatings, etc., can solve the problems of affecting the decorative effect and use value, becoming viscous, losing strength, and easy to become brittle, so as to overcome the two-component limitation and improve weather resistance , Hydrophobic enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1. Synthesis of hydroxyl-terminated polydimethylsiloxane grafted modified acrylic resin

[0023] 1. The mass percentage of raw materials and dosage is

[0024]

[0025] 2. Preparation method

[0026] Mix methyl methacrylate, styrene, isooctyl acrylate, hydroxyethyl acrylate, γ-methacryloxypropyltrimethoxysilane and azobisisobutyronitrile according to the above ratio, stir and dissolve, and dissolve in Add tetrahydrofuran into the reaction vessel, raise the temperature to 70°C, add the mixed monomers dropwise, keep warm for 5 hours after dropping, then add the mixture of dibutyltin dilaurate and hydroxyl-terminated polydimethylsiloxane dropwise, the temperature is controlled at 80°C, React for 1 hour, cool down to room temperature, and discharge.

[0027] 2. Preparation of anticorrosion coating based on modified acrylic resin

[0028] 1. The mass percentage of raw materials and dosage is

[0029]

[0030] 2. Preparation method

[0031] Pour the modified benton...

Embodiment 2

[0033] 1. Synthesis of hydroxyl-terminated polydimethylsiloxane grafted modified acrylic resin

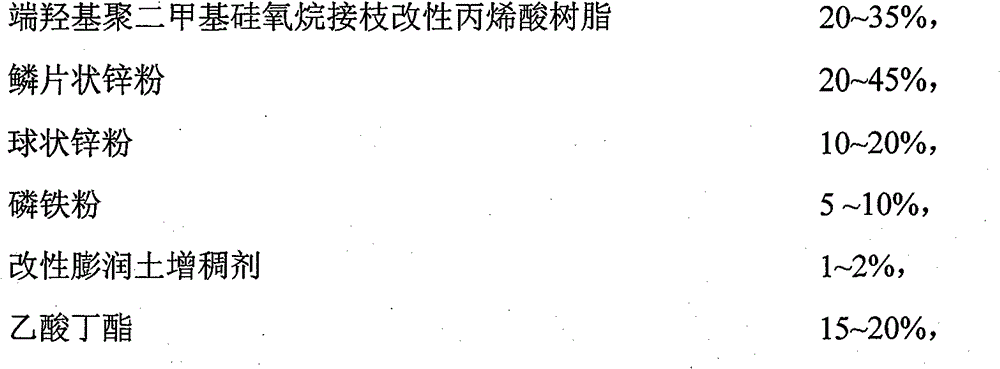

[0034] 1. The mass percentage of raw materials and dosage is

[0035]

[0036] 2. Preparation method

[0037] Mix methyl methacrylate, styrene, isooctyl acrylate, hydroxyethyl acrylate, γ-methacryloxypropyltrimethoxysilane and azobisisobutyronitrile according to the above ratio, stir and dissolve, and dissolve in Add tetrahydrofuran into the reaction vessel, raise the temperature to 80°C, add the mixed monomers dropwise, keep the temperature for 4 hours after dropping, then add the mixture of dibutyltin dilaurate and hydroxyl-terminated polydimethylsiloxane dropwise, the temperature is controlled at 80°C, React for 1 hour, cool down to room temperature, and discharge.

[0038] 2. Preparation of anticorrosion coating based on modified acrylic resin

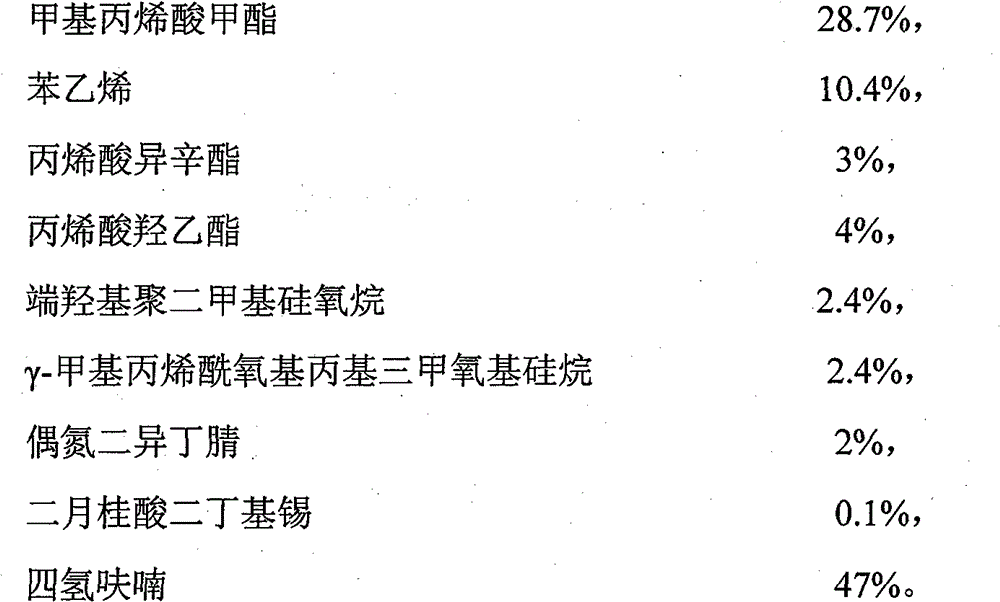

[0039] 1. The mass percentage of raw materials and dosage is:

[0040]

[0041] 2. Preparation method

[0042] Pour the mod...

Embodiment 3

[0044] 1. Synthesis of hydroxyl-terminated polydimethylsiloxane grafted modified acrylic resin

[0045] 1. The mass percentage of raw materials and dosage is:

[0046]

[0047] 2. Preparation method

[0048] Mix methyl methacrylate, styrene, isooctyl acrylate, hydroxyethyl acrylate, γ-methacryloxypropyltrimethoxysilane and azobisisobutyronitrile according to the above ratio, stir and dissolve, and dissolve in Add tetrahydrofuran into the reaction vessel, raise the temperature to 75°C, add the mixed monomers dropwise, keep warm for 4.5 hours after dropping, then add the mixture of dibutyltin dilaurate and hydroxyl-terminated polysiloxane dropwise, control the temperature at 80°C, and react for 1 hour , down to room temperature, and discharge.

[0049] 2. Preparation of anticorrosion coating based on modified acrylic resin

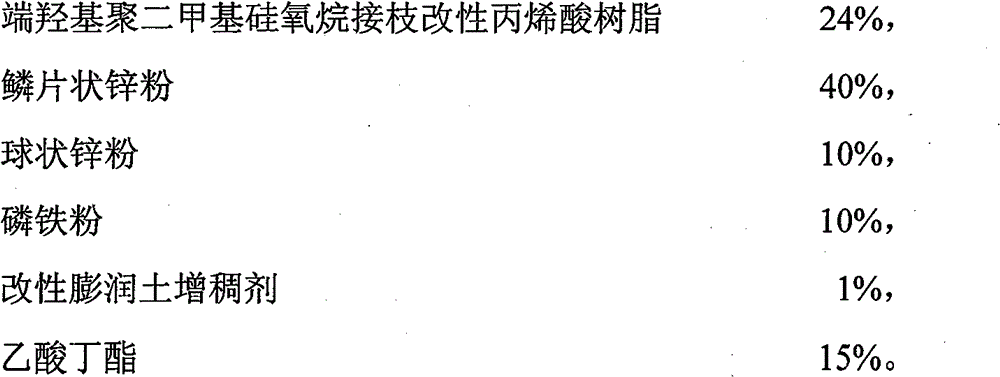

[0050] 1. The mass percentage of raw materials and dosage is:

[0051]

[0052] 2. Preparation method

[0053] Pour the modified bentonite thicke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com