Preparation method of silk fibroin porous three-dimensional material

A technology of silk fibroin and porous material, which is used in medical science, inactive components of polymer compounds, prostheses, etc. It can solve the problems of inability to adjust the structure ratio of silk fibroin I and silk fibroin II, and achieve the effect of good structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Soak about 50g raw silk in 2L 0.5% Na 2 CO 3 solution, stirred and boiled for 30 minutes, then removed and washed with deionized water. After repeating the above operation twice, the silk was dried at 60°C.

[0039] 15 g of the degummed silk after the above treatment was weighed and dissolved in 100 ml of BrLi solution with a concentration of 9.5 mol / L, stirred and dissolved at 60° C. for one hour. Then use a dialysis bag with a molecular weight cut-off of 3500 to dialyze with deionized water for four days to obtain a silk protein aqueous solution with a concentration of 4%, and adjust the concentration of the silk protein aqueous solution to 2%.

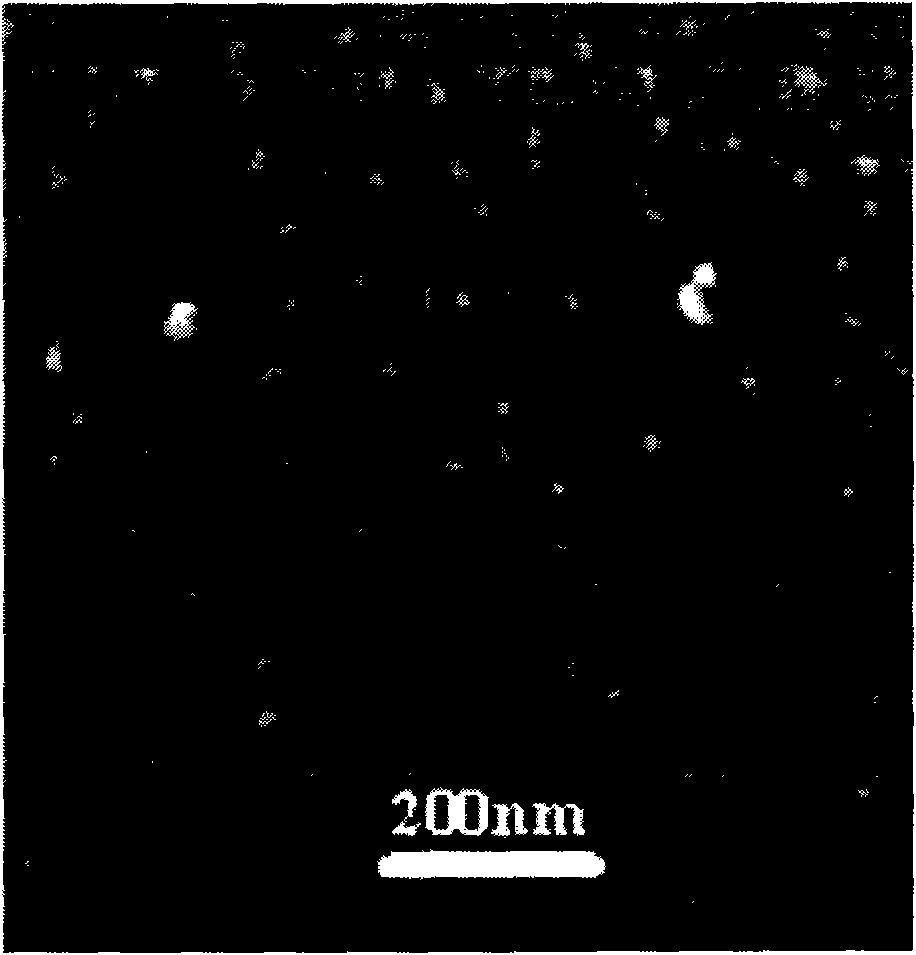

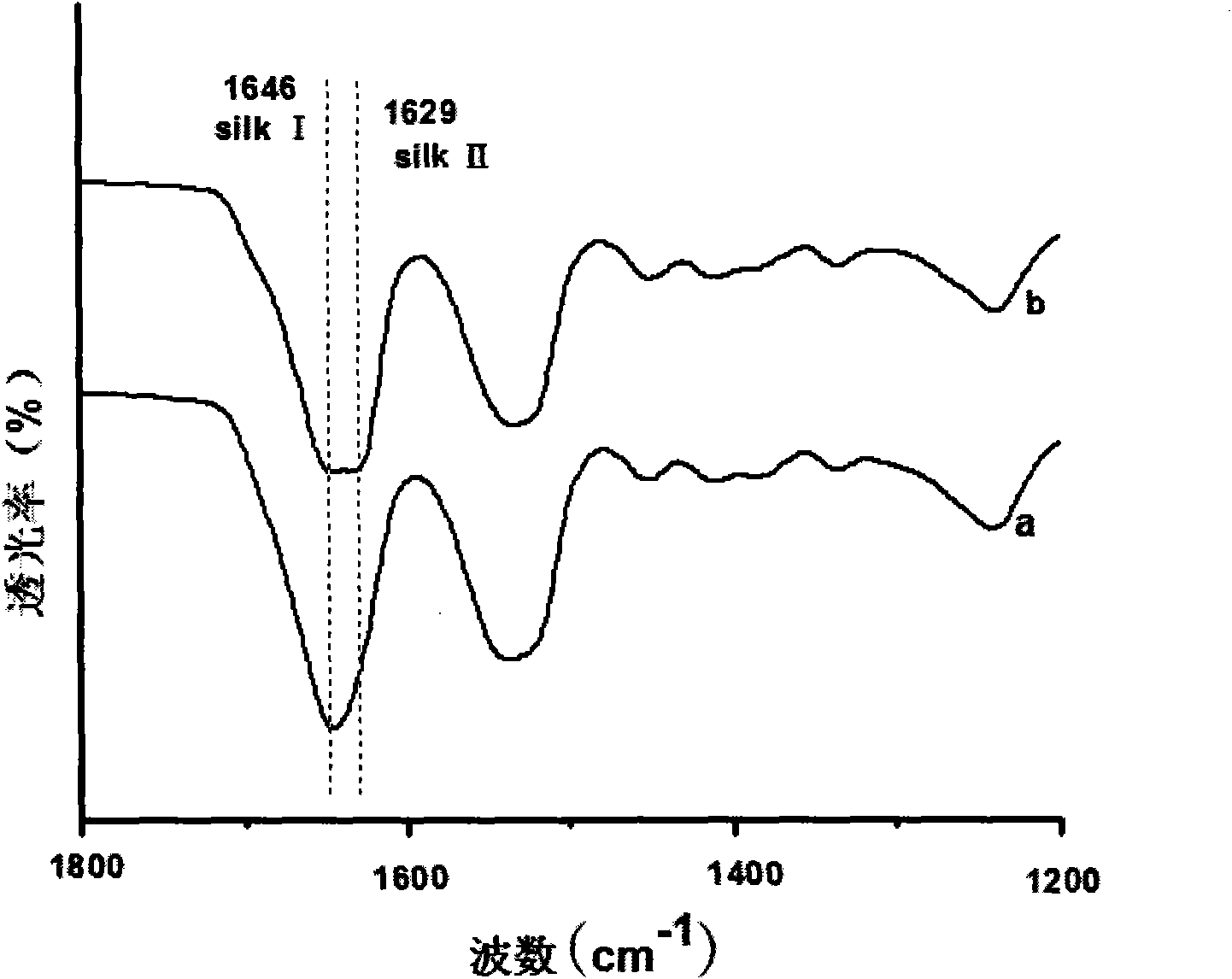

[0040] Take 10 mL of the above-mentioned silk protein solution and incubate in a sealed manner at 60° C. for 48 hours. After incubation, an aqueous solution of silk fibroin nanospheres is obtained. The atomic force microscope image of the silk fibroin nanospheres is shown in figure 1 (Depend on figure 1 It can be seen tha...

Embodiment 2

[0043] Embodiment two: about 50g raw silk is immersed in 2L 0.5%Na 2 CO 3 solution, stirred and boiled for 30 minutes, then removed and washed with deionized water. After repeating the above operation twice, the silk was dried at 60°C.

[0044] 15 g of the degummed silk after the above treatment was weighed and dissolved in 100 ml of BrLi solution with a concentration of 9.5 mol / L, stirred and dissolved at 60° C. for one hour. Then use a dialysis bag with a molecular weight cut-off of 3500 to dialyze with deionized water for four days to obtain a silk protein aqueous solution with a concentration of 4%, and adjust the concentration of the silk protein aqueous solution to 2%.

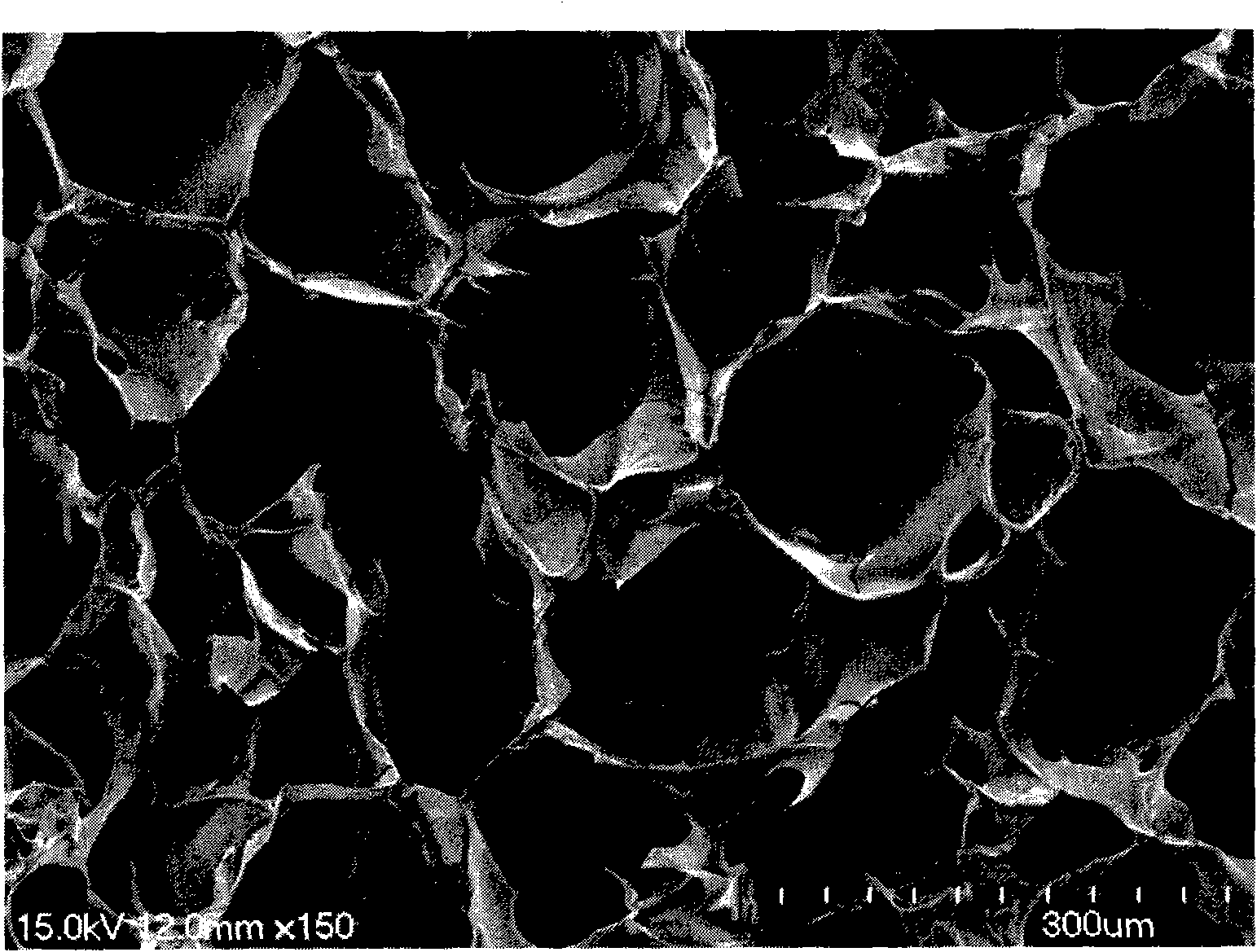

[0045] Take 10 mL of the above silk protein solution, and incubate in a sealed manner at 60° C. for 48 hours, and obtain an aqueous solution of silk fibroin nanospheres after incubation. Then add glycerin accounting for 60% of the mass of the porous scaffold in a dry state, stir evenly, pour into a po...

Embodiment 3

[0048] Soak about 50g raw silk in 2L 0.5% Na 2 CO 3 solution, stirred and boiled for 30 minutes, then removed and washed with deionized water. After repeating the above operation twice, the silk was dried at 60°C.

[0049] 15 g of the degummed silk after the above treatment was weighed and dissolved in 100 ml of BrLi solution with a concentration of 9.5 mol / L, stirred and dissolved at 60° C. for one hour. Then use a dialysis bag with a molecular weight cut-off of 3500 to dialyze with deionized water for four days to obtain a silk protein aqueous solution with a concentration of 4%, and adjust the concentration of the silk protein aqueous solution to 2%.

[0050] Take 10 mL of the above silk protein solution, and incubate in a sealed manner at 60° C. for 48 hours, and obtain an aqueous solution of silk fibroin nanospheres after incubation.

[0051] Then add ethylene glycol accounting for 40% of the mass of the porous scaffold in a dry state, stir evenly, pour into a polyethy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com