Desalination method of waste water

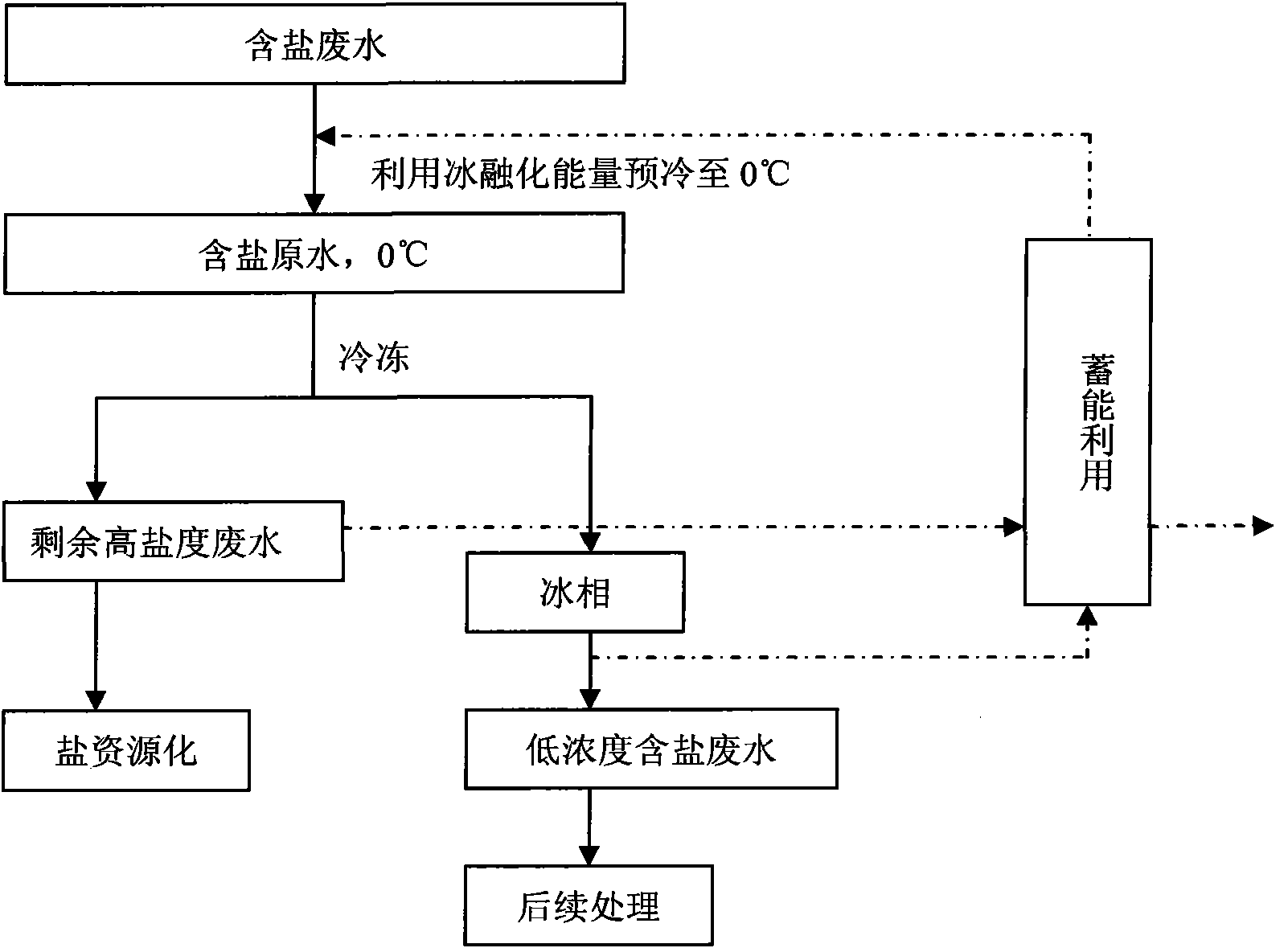

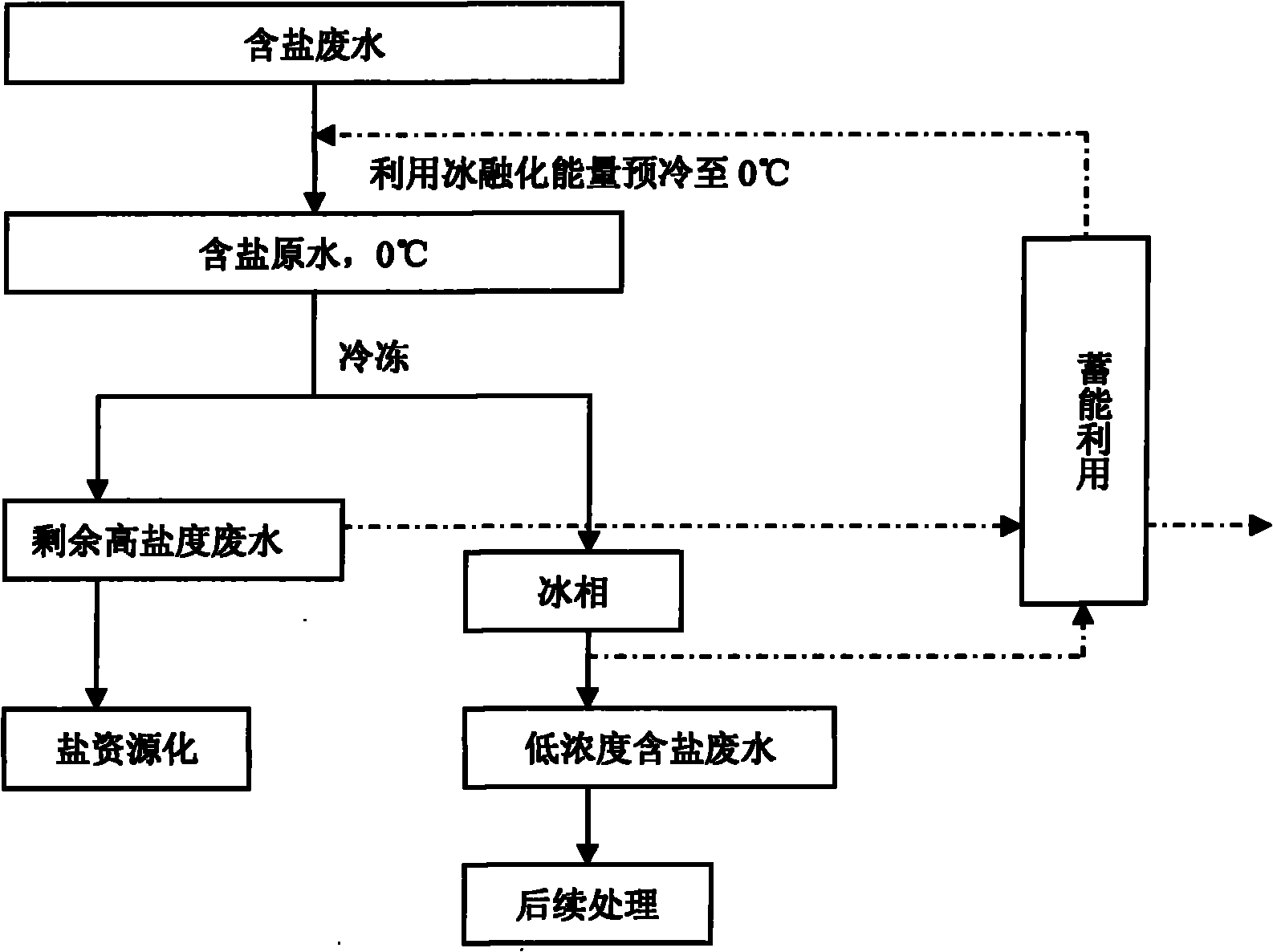

A desalination and wastewater technology, applied in general water supply conservation, chemical instruments and methods, water/sewage treatment, etc., can solve the problems of difficulty in implementation, troublesome operation and maintenance, high energy consumption, reduce energy consumption and improve freezing effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

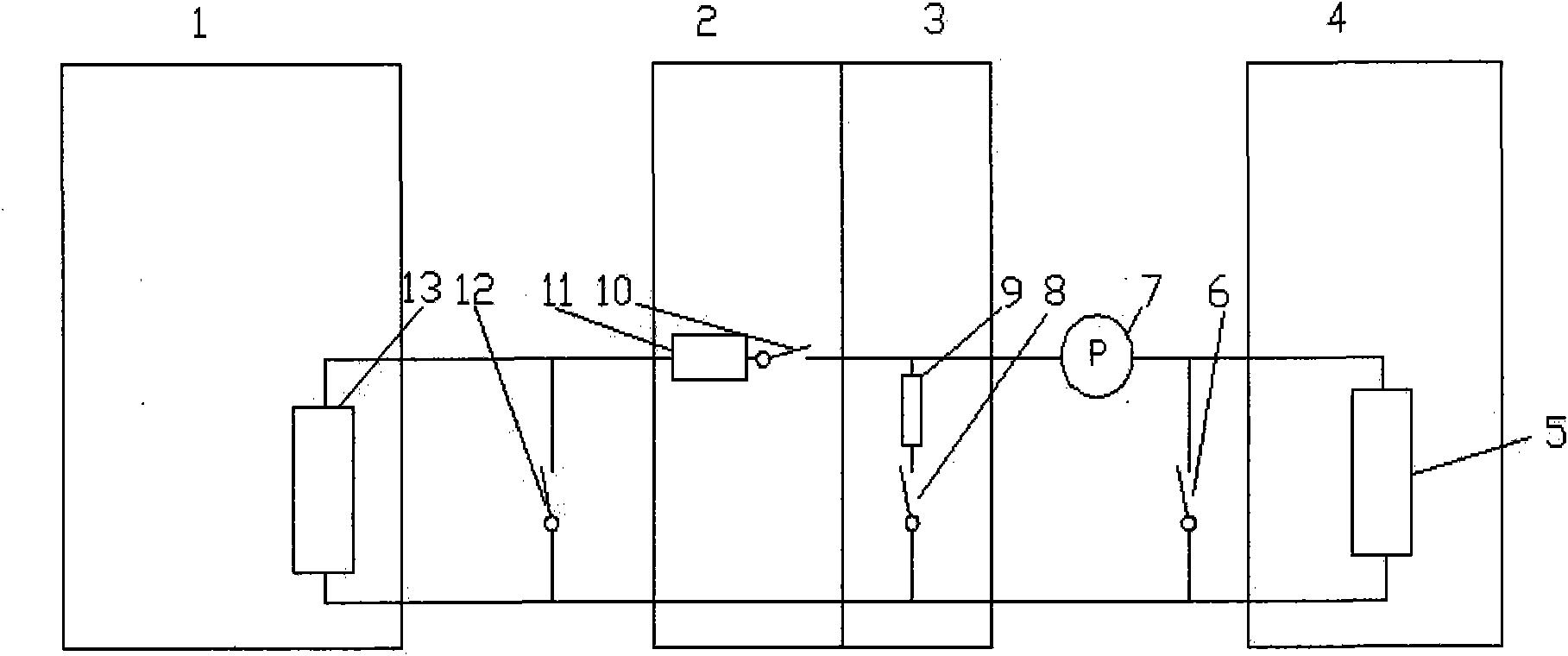

[0021] 10 L of waste brine containing 2% sodium chloride was pumped into raw water tank 1. From 8:00 to 10:00, switches 6 and 10 are turned on, switches 8 and 12 are turned off, heat pumps 11 and 13 work, and the raw water is pre-cooled to 0°C. The ice phase in the fresh water tank 2 melts.

[0022] The waste water pre-cooled to 0°C in the raw water tank 1 is pumped into the ice making / fresh water tank 2 through a pump. From 21:00 to 5:00 the next day, switches 6, 10, and 12 are closed, switch 8 is opened, and heat pump 11 works. 10 L of 2% sodium chloride containing waste brine at 0°C was frozen for 8 hours at a freezing temperature of -16°C. Freezing yields two phases of residual brine and ice. The volume of the remaining brine was 4.6 L and the sodium chloride content was 3.97%.

[0023] The remaining brine with a sodium chloride content of 3.97% in the ice-making / freshwater tank 2 was pumped into the high-concentration brine tank 3 through a pump. During the period fr...

Embodiment 2

[0027] 10 L of waste brine containing 4% sodium chloride was pumped into raw water tank 1. From 8:00 to 10:00, switches 6 and 10 are turned on, switches 8 and 12 are turned off, heat pumps 11 and 13 work, and the raw water is pre-cooled to 0°C. The ice phase in the fresh water tank 2 melts.

[0028] The waste water pre-cooled to 0°C in the raw water tank 1 is pumped into the ice making / fresh water tank 2 through a pump. From 21:00 to 7:00 the next day, switches 6, 10, and 12 are closed, switch 8 is opened, and heat pump 11 works. 10 L of 4% sodium chloride containing waste brine at 0°C was frozen for 10 hours at a freezing temperature of -18°C. Freezing yields two phases of residual brine and ice. The volume of the remaining brine was 4.1 L and the sodium chloride content was 8.60%.

[0029] The remaining brine with a sodium chloride content of 8.60% in the ice-making / freshwater tank 2 is pumped into the high-concentration brine tank 3 through a pump. During the period fr...

Embodiment 3

[0033] 10 L of waste brine containing 5% sodium chloride was pumped into raw water tank 1. From 8:00 to 10:00, switches 6 and 10 are turned on, switches 8 and 12 are turned off, heat pumps 11 and 13 work, and the raw water is pre-cooled to 0°C. The ice phase in the fresh water tank 2 melts.

[0034] The waste water pre-cooled to 0°C in the raw water tank 1 is pumped into the ice making / fresh water tank 2 through a pump. From 21:00 to 4:00 the next day, switches 6, 10, and 12 are closed, switch 8 is opened, and heat pump 11 works. 10 L of 5% sodium chloride containing waste brine at 0°C was frozen for 7 hours at a freezing temperature of -15°C. Freezing yields two phases of residual brine and ice. The volume of the remaining brine was 5.1 L and the sodium chloride content was 8.60%.

[0035] The remaining brine with a sodium chloride content of 8.60% in the ice-making / freshwater tank 2 is pumped into the high-concentration brine tank 3 through a pump. During the period fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com