Titania nanotube/nanorod microspheres with hierarchical structure and preparation method thereof

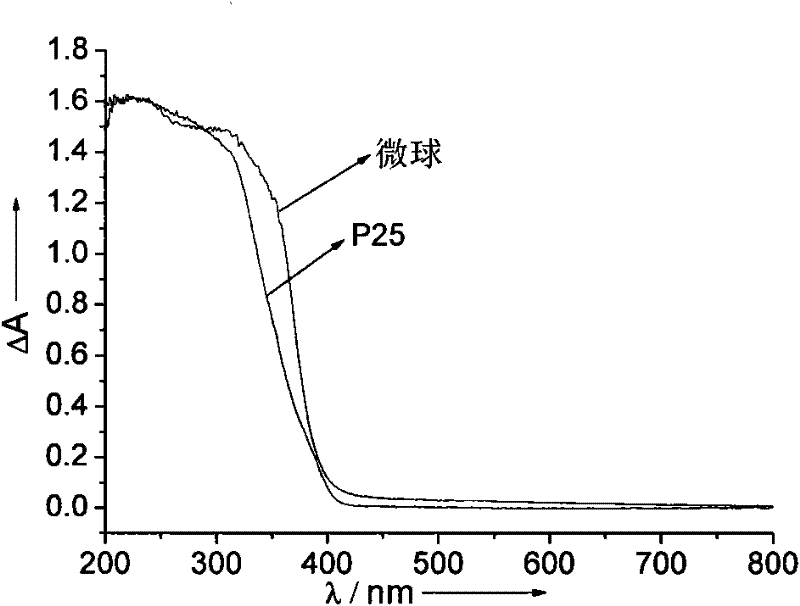

A technology of titanium dioxide and nanotubes, applied in the field of titanium dioxide nanotube/nanorod microspheres with hierarchical structure and its preparation, can solve the problems of small specific surface area of microspheres, and achieve easy recycling, large industrialization value, and strong ultraviolet absorption effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] First, a general method was used to synthesize the precursor of titanium dioxide microspheres under hydrothermal conditions: 5.1 g of tetrabutyl titanate was dropped into 75 mL of absolute ethanol under stirring, and then 0.33 mL of concentrated sulfuric acid (98%) and 0.3 mL were added. Ionized water, put the mixture into an autoclave with a volume of 110 mL with a polytetrafluoroethylene lining, react at 180°C for 4 hours, naturally cool to room temperature, take out, filter, and dry at 40°C for 5 hours before use. The precursor is composed of random nanoparticles with a diameter of 4-6μm; 0.5g of the microsphere precursor is placed in 50mL of 10M sodium hydroxide solution, magnetically stirred for 0.5h, and the mixed solution is placed in a volume of 80mL In an autoclave lined with polytetrafluoroethylene, react at 150°C for 24h, cool to room temperature naturally, take out and filter, wash with deionized water to neutrality, and redisperse the product in 600mL dilute ...

Embodiment 2

[0032] First, a general method was used to synthesize the titanium dioxide microsphere precursor (same as Example 1); 0.5g of the microsphere precursor was put into 50mL of 10M sodium hydroxide solution, magnetically stirred for 0.5h, and the mixed solution was put into In an 80mL autoclave lined with polytetrafluoroethylene, react at 150℃ for 24h, cool to room temperature naturally, take out and filter, wash with deionized water to neutrality, and redisperse the product in 600mL dilute hydrochloric acid with a concentration of 0.1M After stirring for 12 hours at room temperature, washing with deionized water to neutrality, drying at 40°C for 5 hours, and annealing the product at 500°C for 1 hour, titanium dioxide nanorod microspheres with hierarchical structure of anatase phase can be obtained.

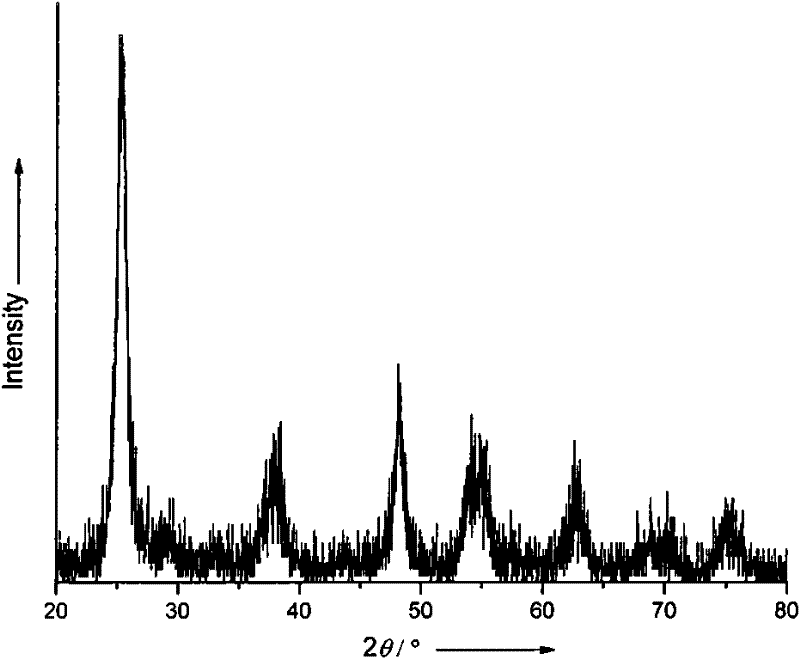

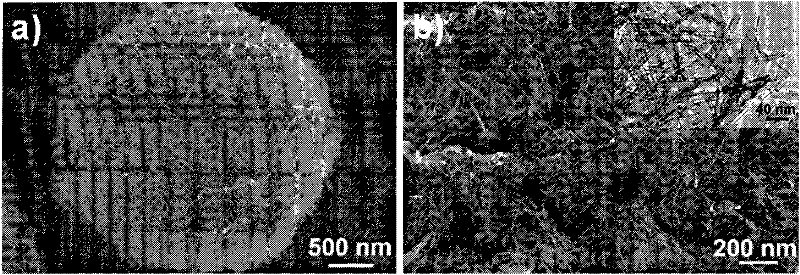

[0033] Attached Figure 4 This is the X-ray diffraction pattern of the product obtained in this example. It can be seen from the figure that the product is pure anatase TiO 2 . Attached...

Embodiment 3

[0035] First, a general method was used to synthesize the titanium dioxide microsphere precursor (same as Example 1); 0.5g of the microsphere precursor was put into 50mL of 5M sodium hydroxide solution, magnetically stirred for 0.5h, and the mixture was placed in a volume of In an 80mL autoclave lined with polytetrafluoroethylene, react at 180℃ for 24h, cool to room temperature naturally, take out and filter, wash with deionized water to neutrality, and redisperse the product in 600mL dilute hydrochloric acid with a concentration of 0.1M Stir at room temperature for 12h, wash with deionized water to neutrality, dry at 40℃ for 5h, and annealed the product at 400℃ for 1h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com