Vertical single-column cantilever type large-aperture honing machine

A cantilever-type, single-column technology, applied in honing machine tools, metal processing equipment, manufacturing tools, etc., can solve problems such as low requirements for alignment and alignment, complex structure of ball-joint connecting rods, and reduced strength of connecting rods, etc., to achieve Eliminate jamming, simplify the process of workpiece alignment, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

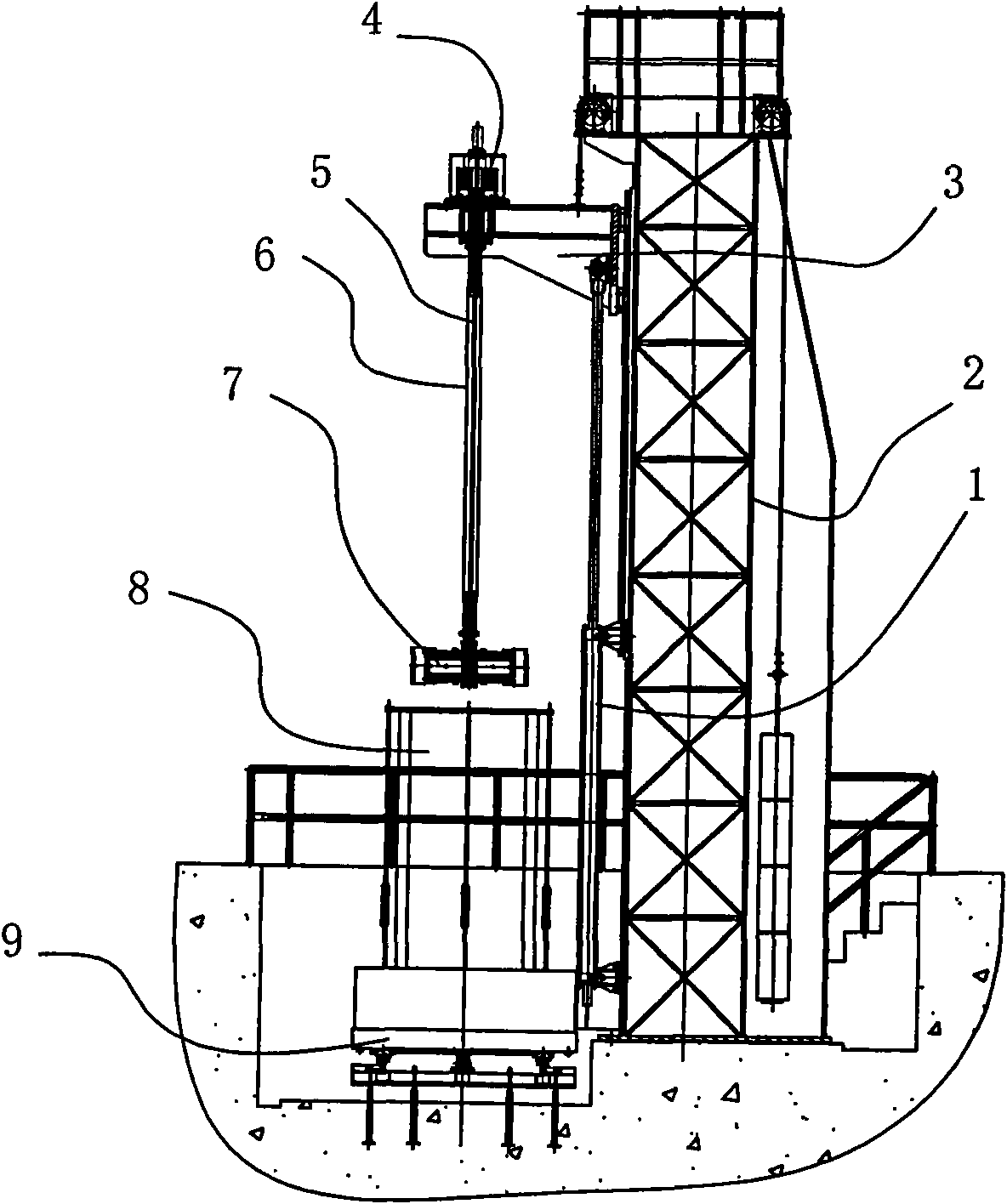

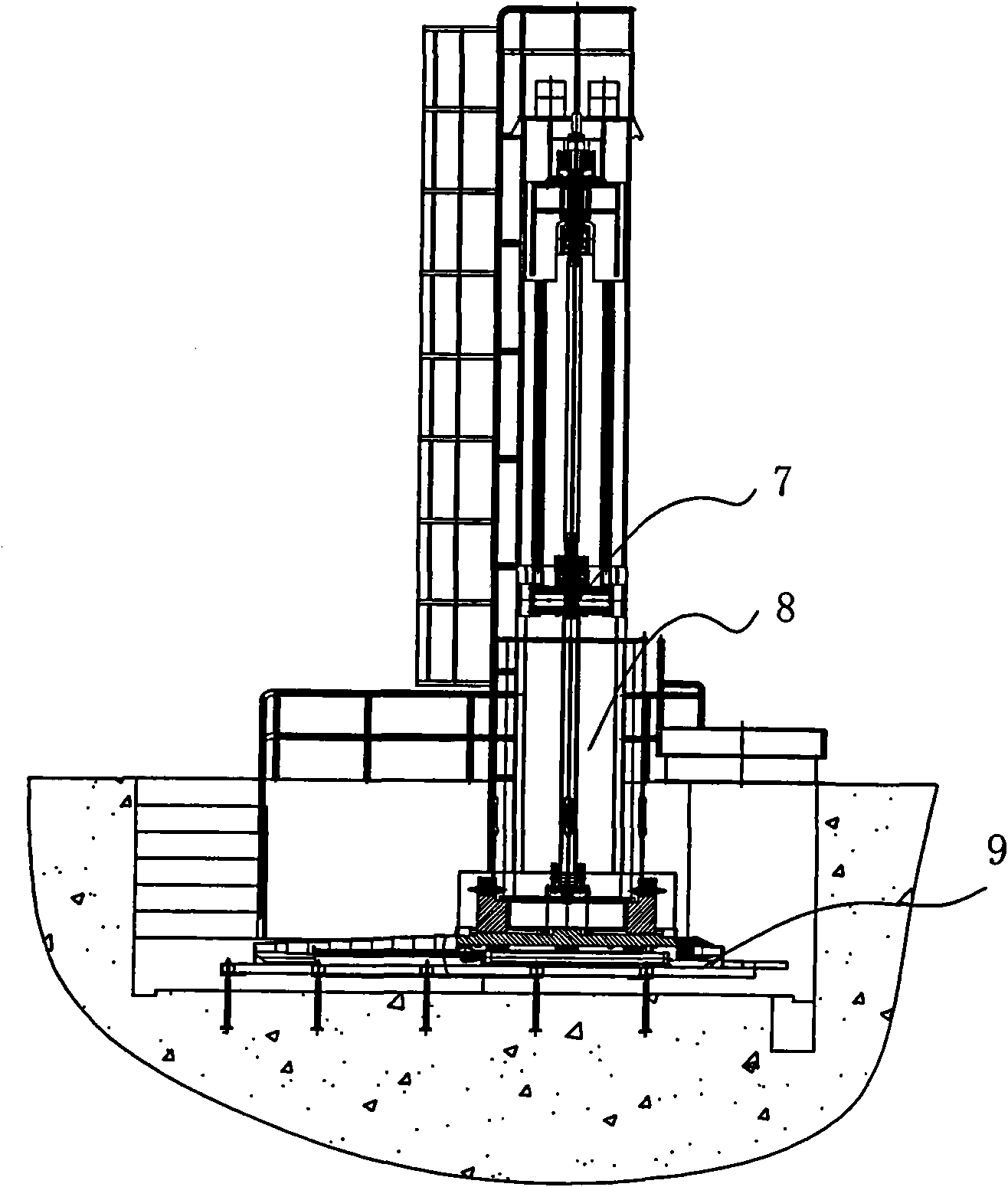

[0022] The invention as Figure 1-5 As shown, including frame 2, workbench 9, honing head device and honing head device lifting drive mechanism;

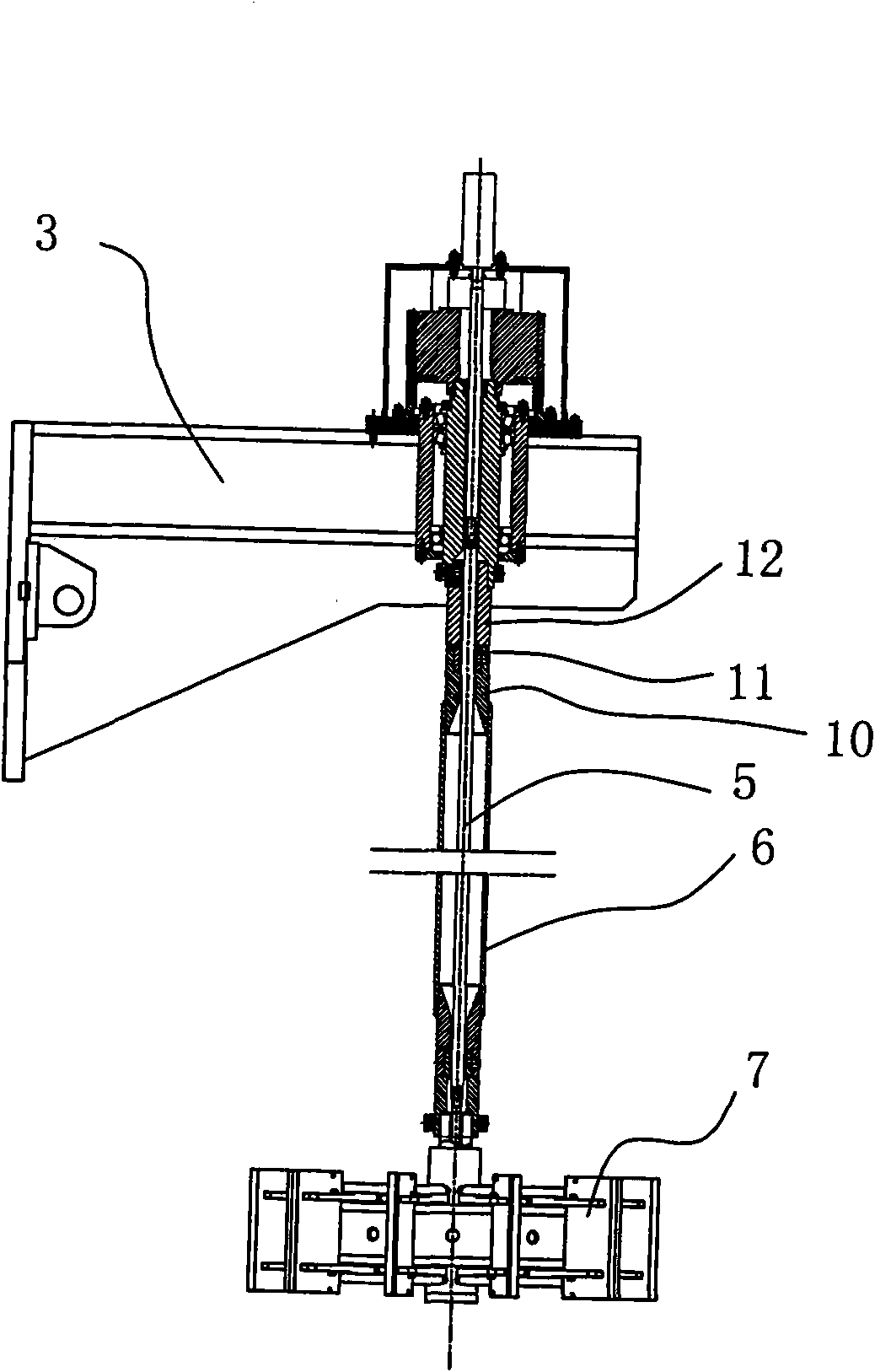

[0023] The lifting drive mechanism of the honing head device includes a cantilever-type lifting seat 3 and a lifting cylinder 1; the lifting cylinder 1 is fixedly connected to the side of the frame 2 to drive the lifting seat 3 to move up and down; the honing head device Connected to the lifting seat 3, the honing head device is perpendicular to the horizontal plane;

[0024] Described workbench 9 comprises the base and the platen 14 of horizontal setting, and platen 14 is connected with base by linear guide rail 15; Described platen 14 is provided with fixture 13; The longitudinal axis level of described workbench 9, and with all The axes of the honing head device are in the same vertical plane;

[0025] The honing head device is an expansion-contracting honing head device comprising a drive hydraulic motor 4, a hollow shaft 6, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com