Welding setting device, welding robot system and welding setting method

A welding robot and setting device technology, applied in welding equipment, arc welding equipment, metal processing equipment, etc., can solve the problems of shortened welding time and inability to realize welding, and achieve the effect of shortening welding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

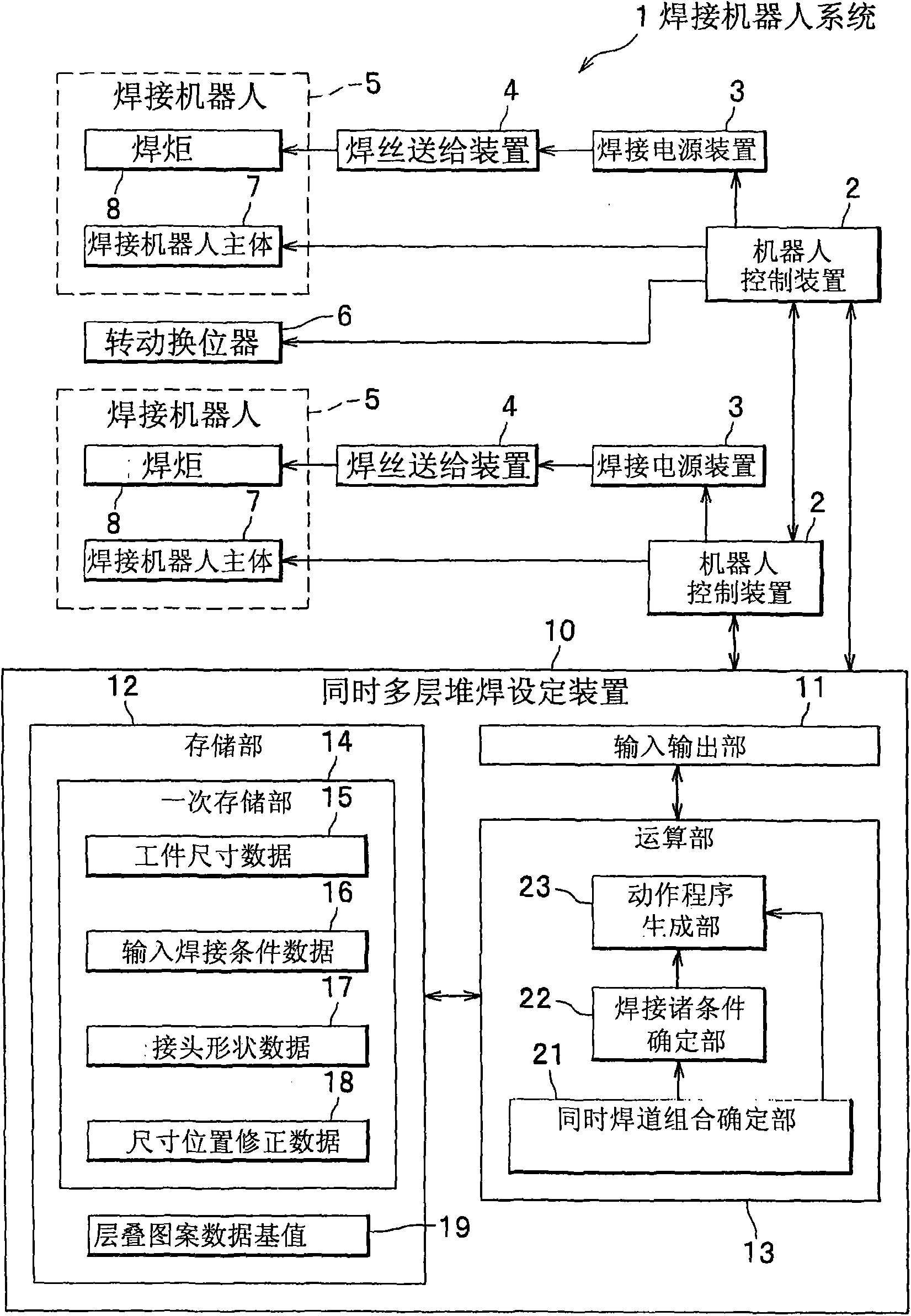

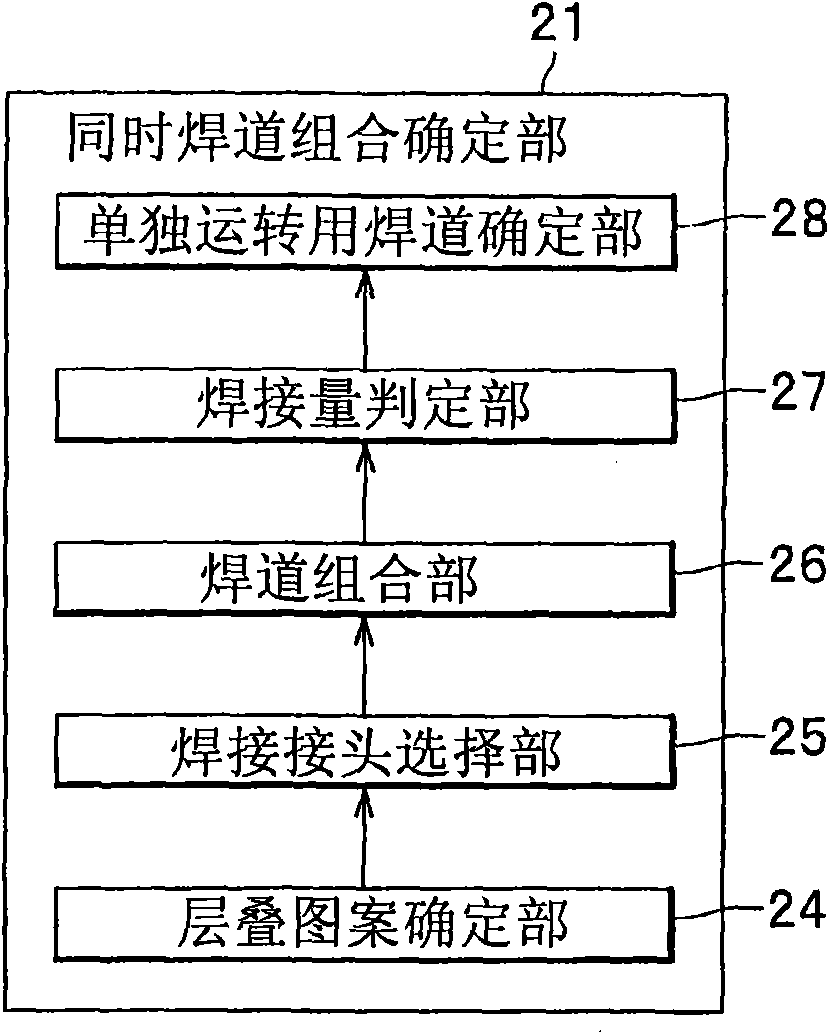

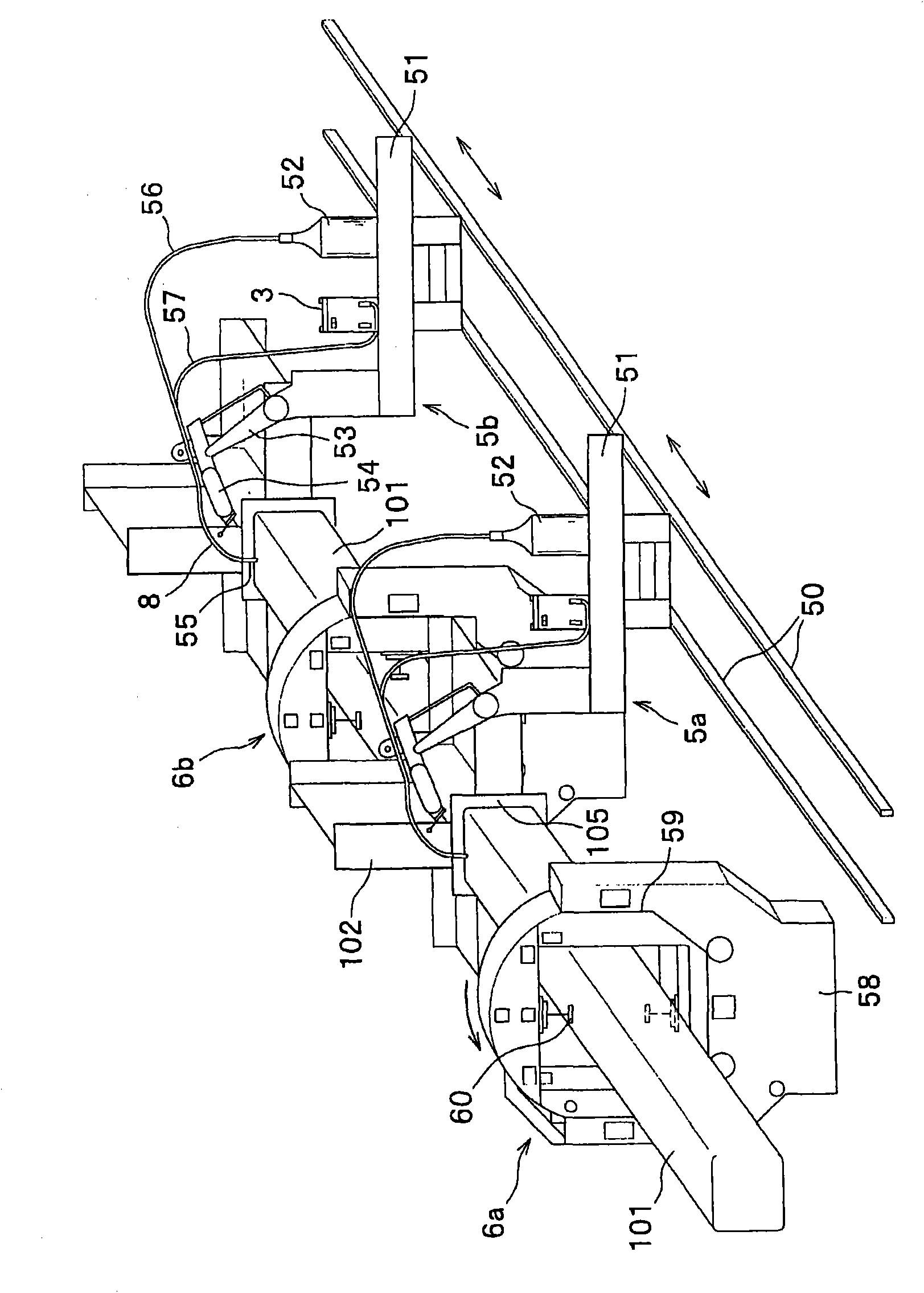

[0043] The welding robot system 1 of the embodiment of the present invention is as figure 1 As shown, it is equipped with a robot control device 2 , a welding power supply device 3 , a welding wire feeding device 4 , a welding robot 5 , a rotary positioner (positioner) 6 , and a setting device 10 for simultaneous multi-layer surfacing welding. Figure 12 shows a configuration example of a control block, which shows that in addition to setting the simultaneous multi-layer overlay welding in the welding robot system 1, it is also used to perform pre-processing for setting the simultaneous multi-layer overlay welding, pre-processing before welding, and The details of the control between each device of the welding process. Below, first, refer to figure 1 The outline of the welding robot system 1 and the outline of the configuration of the simultaneous multi-layer build-up welding setting device will be described. Figure 12 The detailed description will be mentioned later.

[0...

no. 2 approach

[0132] The simultaneous multilayer build-up welding setting device of the second embodiment differs from the first embodiment in that it performs adjustment processing of the joint position of the circular pipe during the simultaneous multilayer build-up welding. Therefore, the same structures as those of the simultaneous multi-layer build-up welding setting device 10 of the first embodiment are denoted by the same reference numerals, and descriptions thereof are appropriately omitted. First, the prerequisite conditions in the simultaneous multilayer build-up welding setting device (welding setting device) 10 of the second embodiment will be described.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com