Device and method for detecting filet weld welding trace based on laser ranging

A technology of laser ranging and detection devices, which is applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as complex structures and expensive prices, and achieve the effects of improving production efficiency, shortening welding time, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the technical means and effects realized by the present invention easy to understand, the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

[0047]

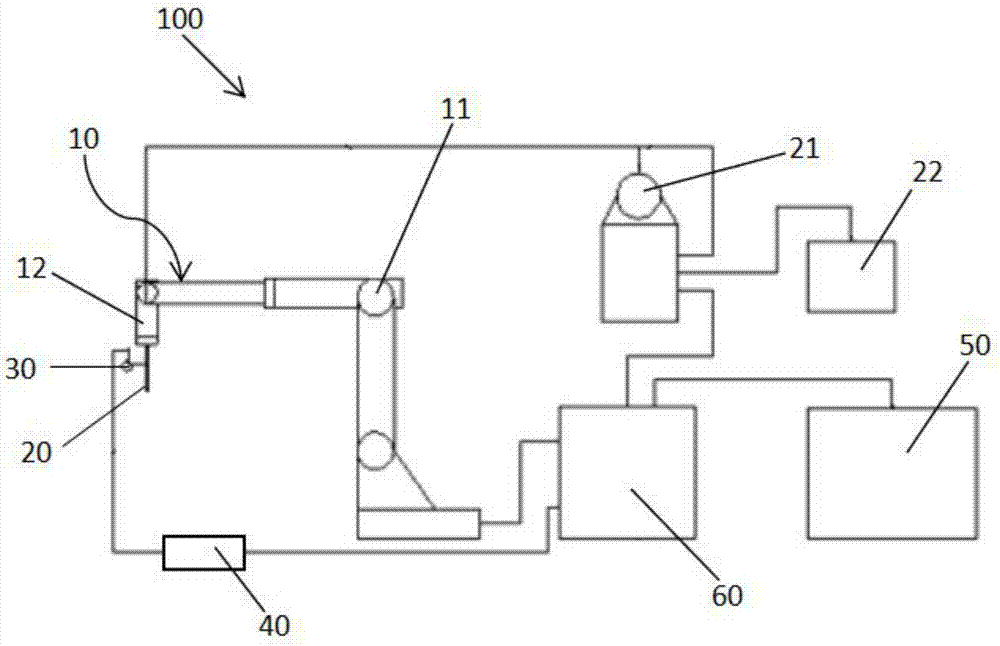

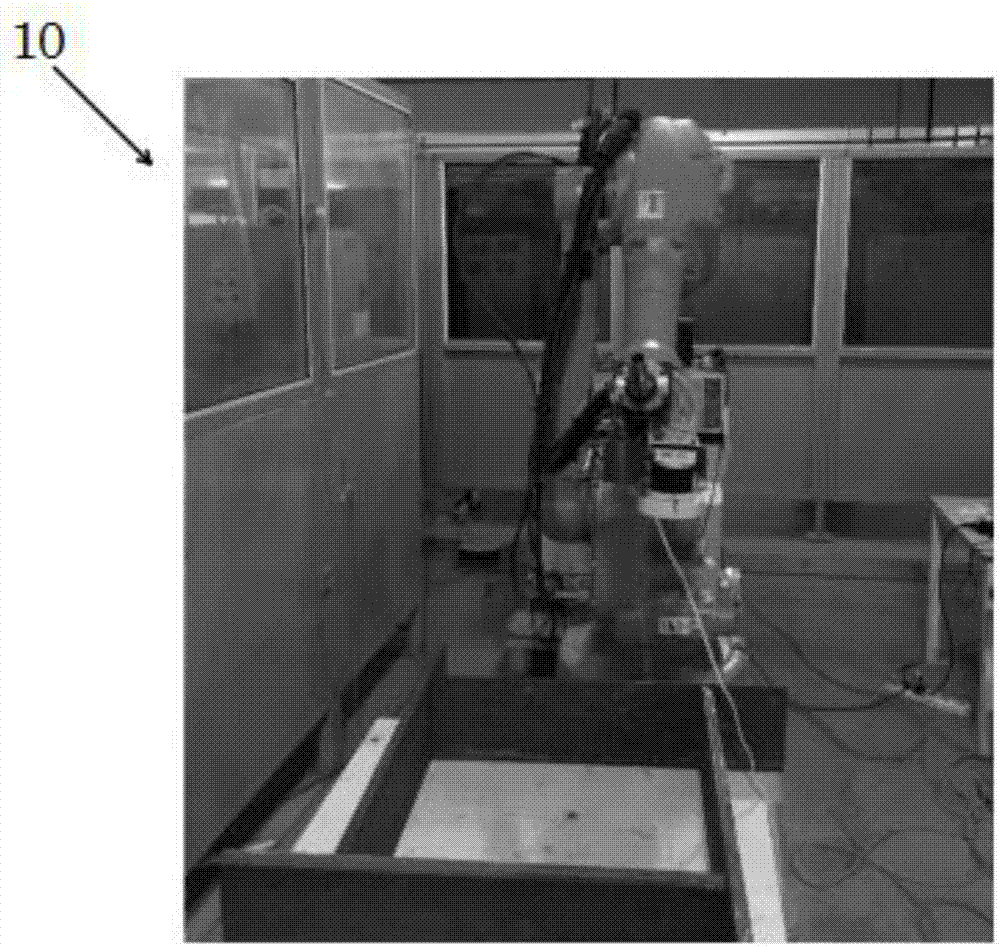

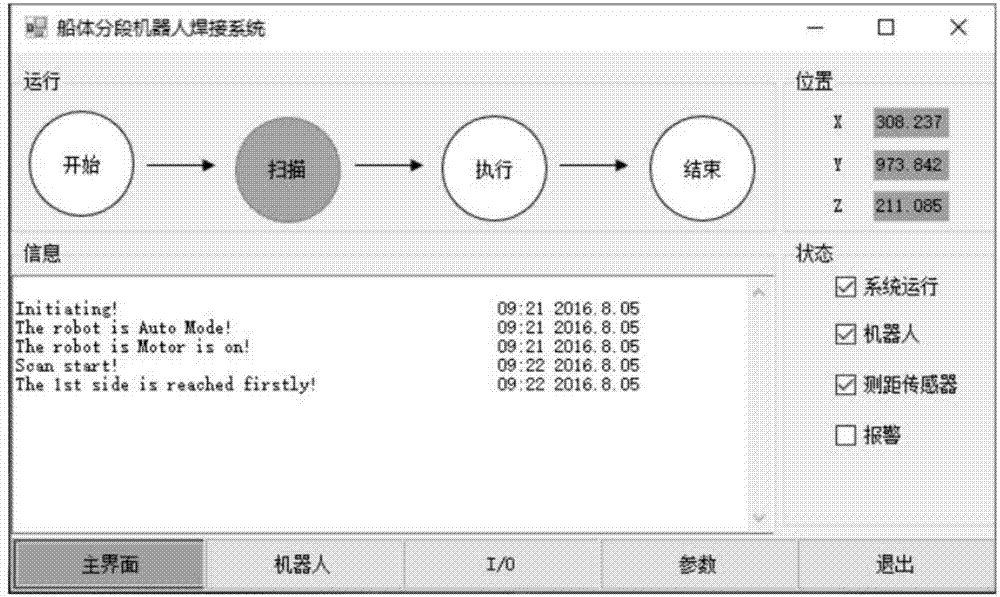

[0048] figure 1 It is a schematic plan view of a fillet weld welding trajectory detection device based on laser ranging in an embodiment of the present invention, figure 2 is a physical schematic diagram of the robot in the embodiment of the present invention, image 3 is a schematic diagram of the display input unit in the embodiment of the present invention.

[0049] Such as figure 1 , figure 2 and image 3 As shown, the device 100 for detecting the welding track of fillet welds based on laser ranging uses laser ranging and performs autonomous positioning and automatic welding of the welds of fillet welds 1, including: a robot 10, a welding torch 20, a laser ranging Sensor 30, Beckhoff module 40, main control computer 50, robot co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com