Method and device for quickly dehydrating investment casting mould materials

A rapid dehydration and investment casting technology, which is applied in the direction of casting molding equipment, molds, mold components, etc., can solve the problems of high energy consumption and low processing efficiency, achieve low energy consumption, improve separation factor, and fast processing speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

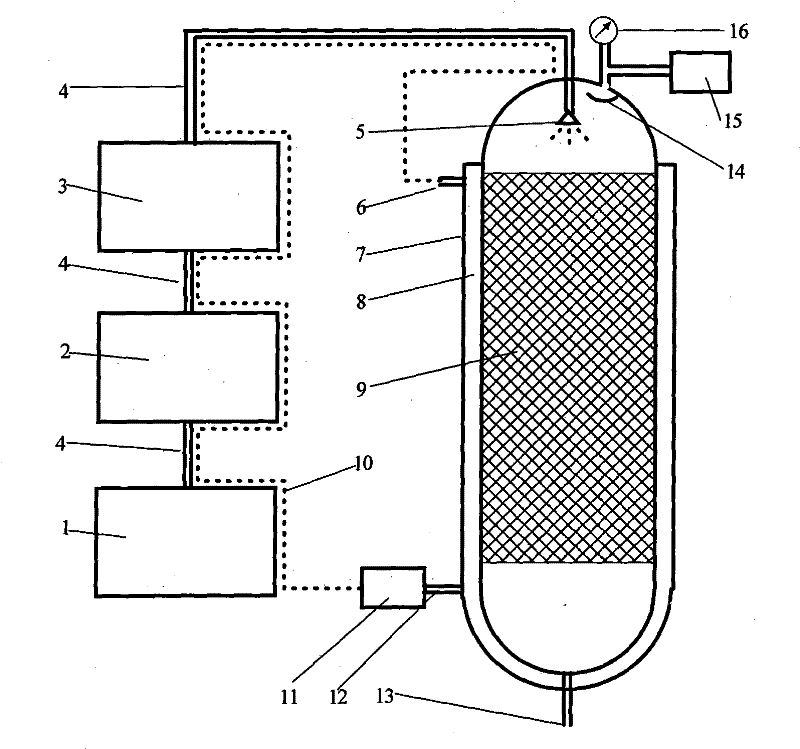

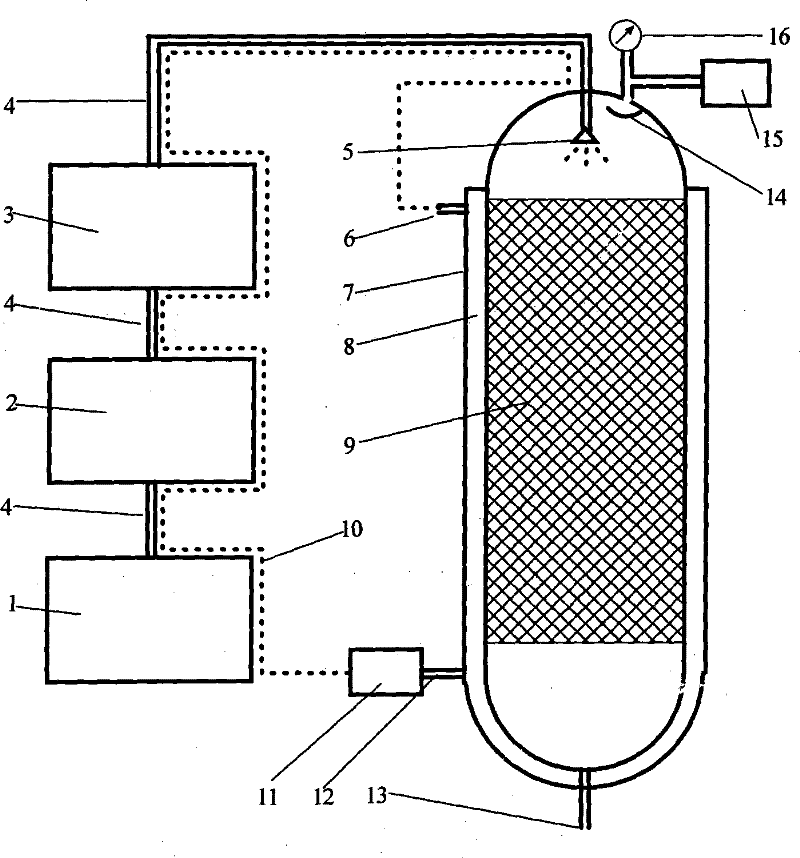

[0014] A rapid dehydration method for investment casting mold material, characterized in that the water-containing mold material is placed in a storage mixing tank, heated to 70-120°C while stirring, and transported to a vertical vacuum dehydration tower by a delivery pipeline and a thermal insulation pump Dehydration, use the heating system between the storage mixing tank and the vacuum vertical vacuum dehydration tower to preheat the conveying pipeline, heat preservation pump and vertical vacuum dehydration tower to 70-120°C when heating the water-containing mold material before conveying the water-containing mold material ;In the dehydration process, the water-containing mold material is first filtered through a 40-80 mesh filter, and then the liquid distribution nozzle on the top of the vertical vacuum dehydration tower enters the vertical vacuum dehydration tower with packing or trays with a heat preservation pump and a delivery pipeline Dehydration, while dehydrating, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com