High frequency range and high power frequency hopping filter

A filter and high-power technology, applied in the field of frequency hopping filters, can solve the problems of large product volume, poor selectivity in high frequency band, large insertion loss, etc., and achieve good filter selectivity, excellent filtering effect, and insertion loss. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

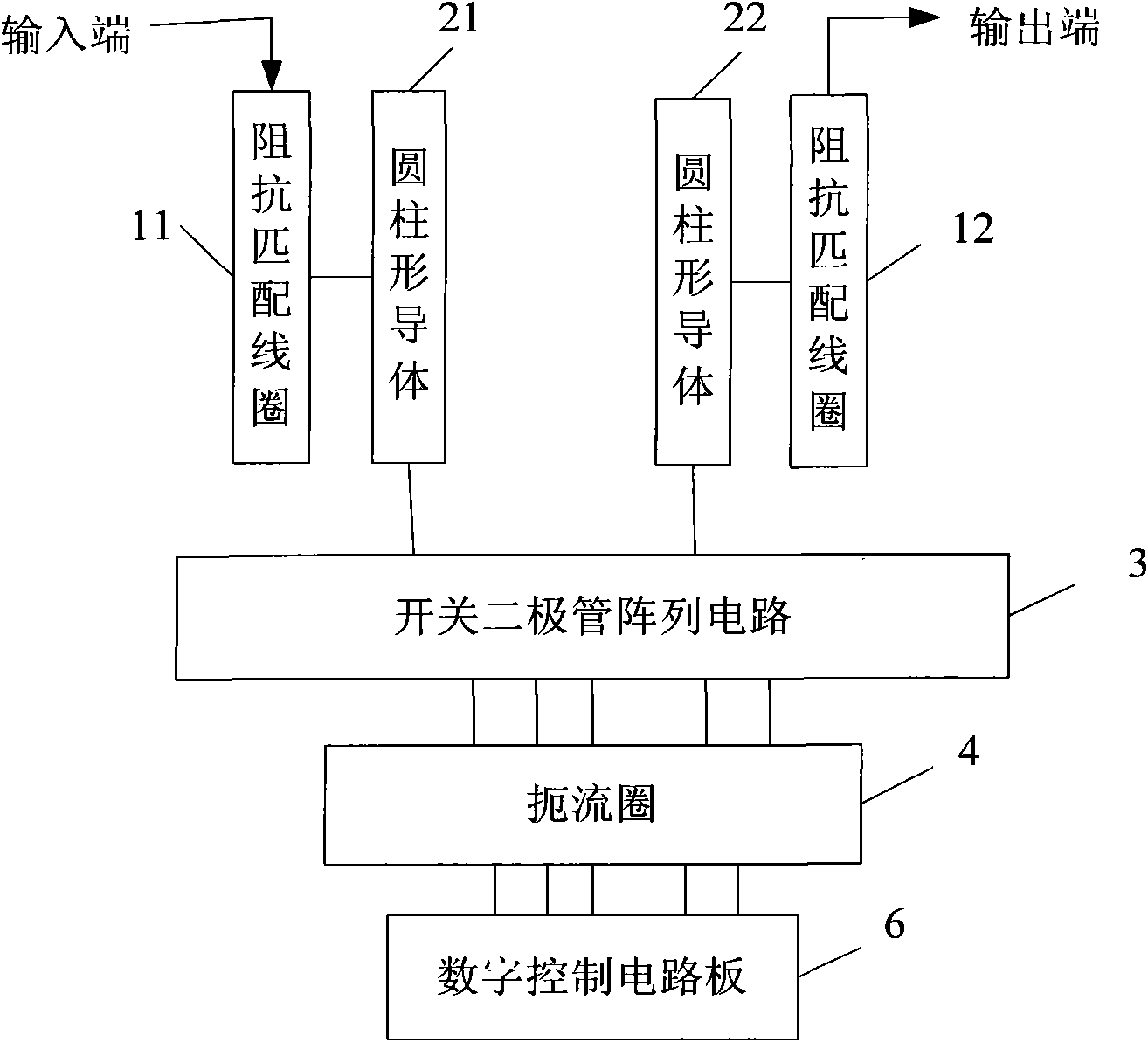

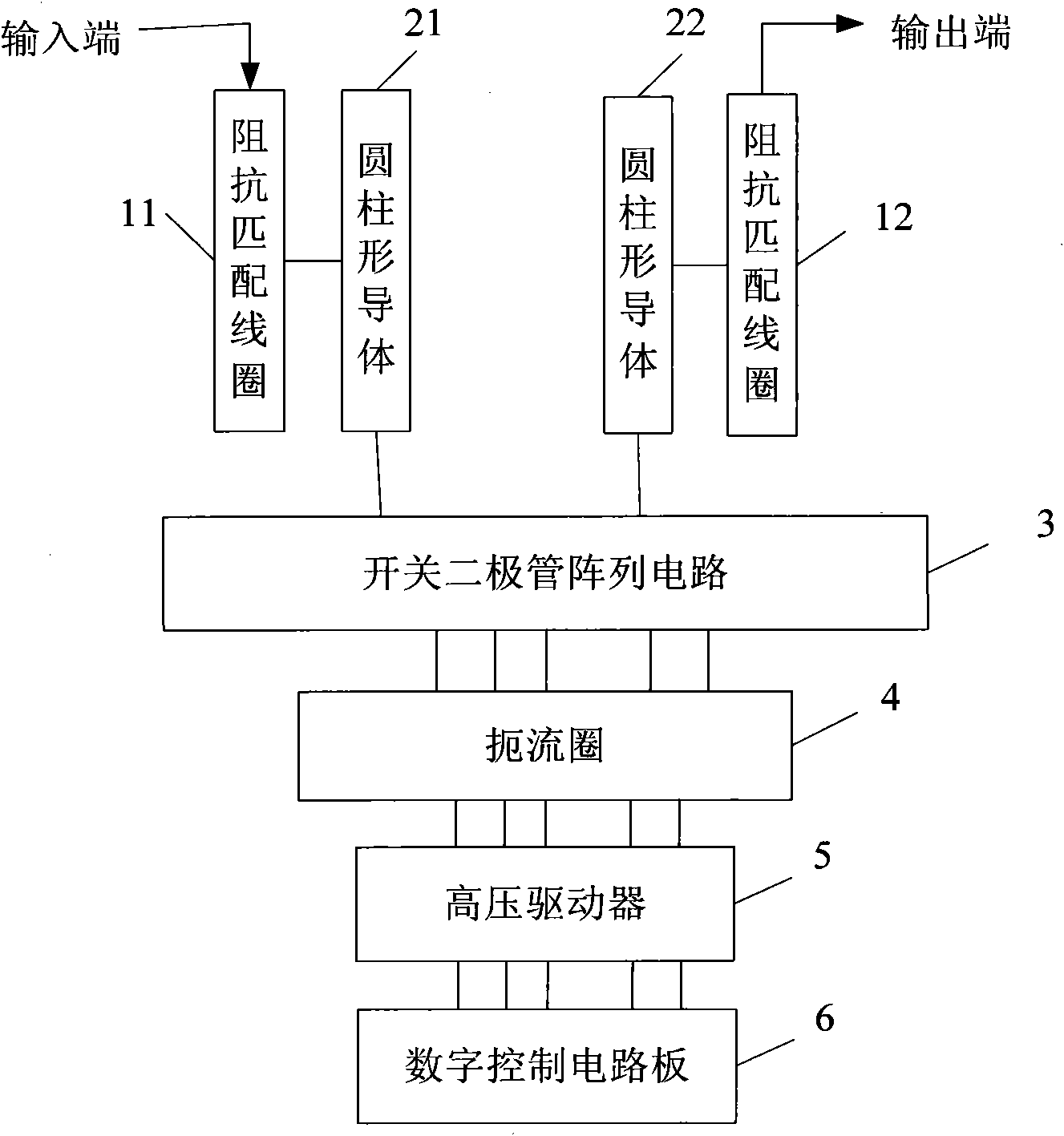

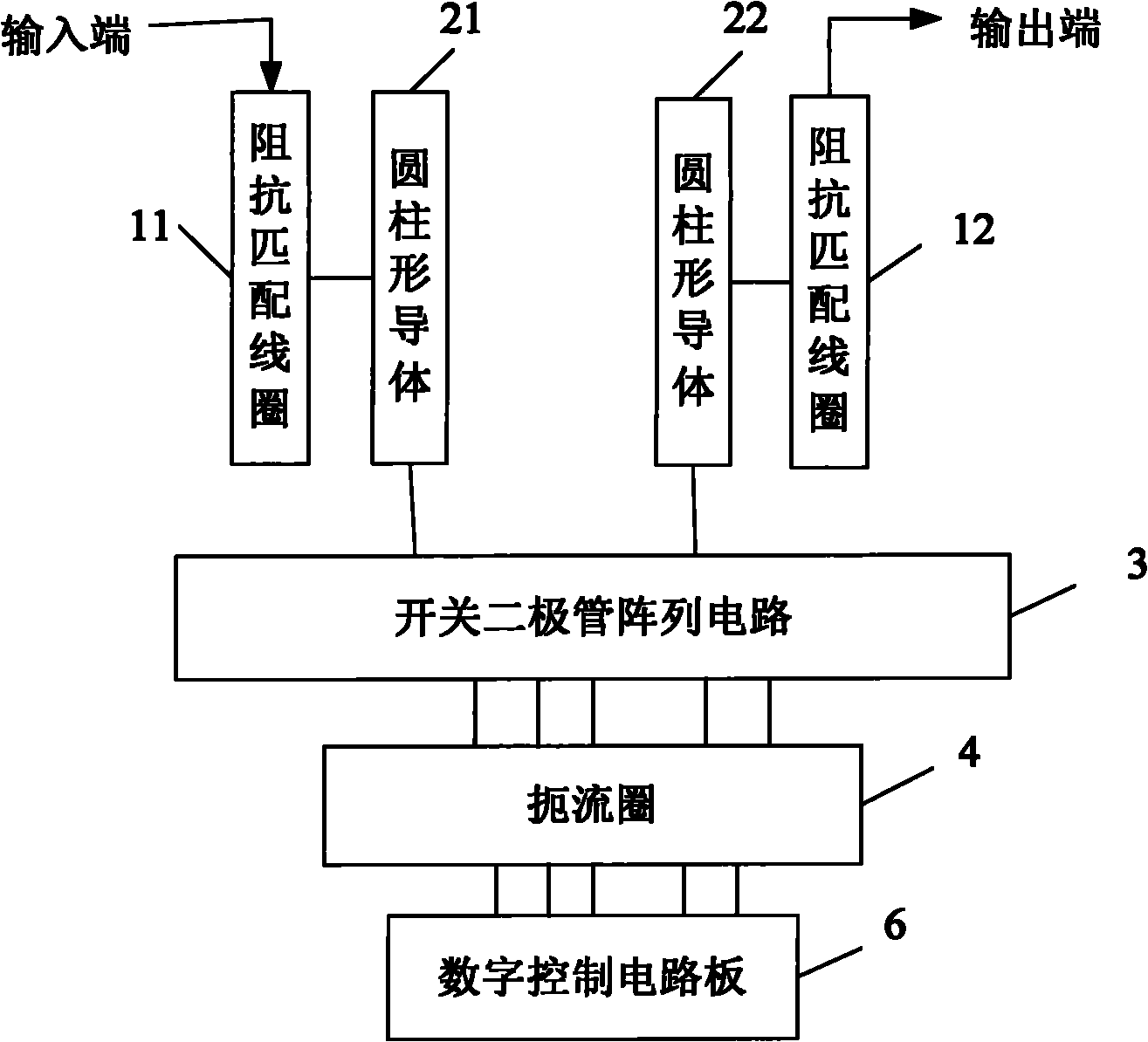

[0015] Such as figure 1 As shown, Embodiment 1 of the present invention provides a high-frequency high-power frequency-hopping filter. In the metal casing, the cavity structure resonator is connected to the switching diode array circuit 3, the choke coil 4 and the frequency-hopping filter for controlling the frequency-hopping filter in sequence. The digital control circuit board 6 is connected; the cavity structure resonator is composed of two cylindrical conductors with a length of 1 / 4 wavelength and two impedance matching coils arranged in an independent cavity. Specifically, the signal input end of the filter is sequentially connected to the impedance matching coil 11 , the cylindrical conductor 21 and the switch diode array circuit 3 . The input signal is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com