LED chip and manufacturing method thereof

A technology of light-emitting diodes and manufacturing methods, which is applied in the field of lighting, can solve problems such as reducing the area of light-emitting diodes, achieve uniform current distribution, improve luminous efficiency, and increase the effect of light-emitting area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

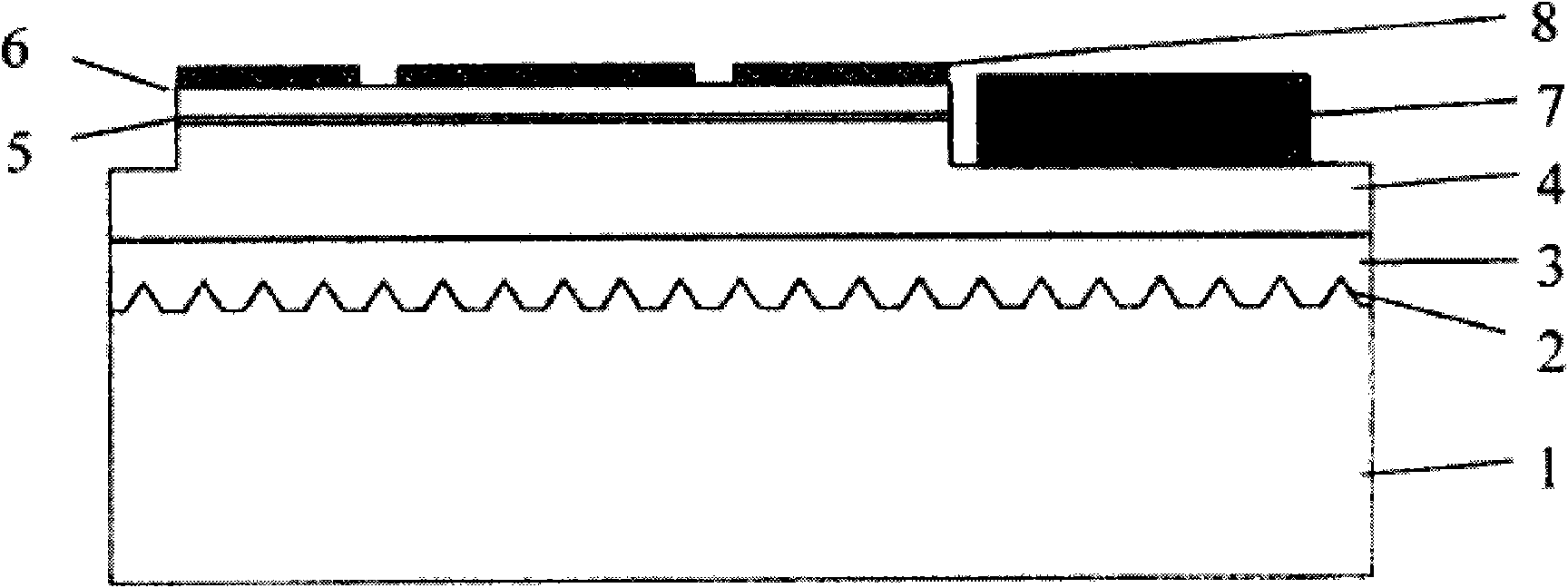

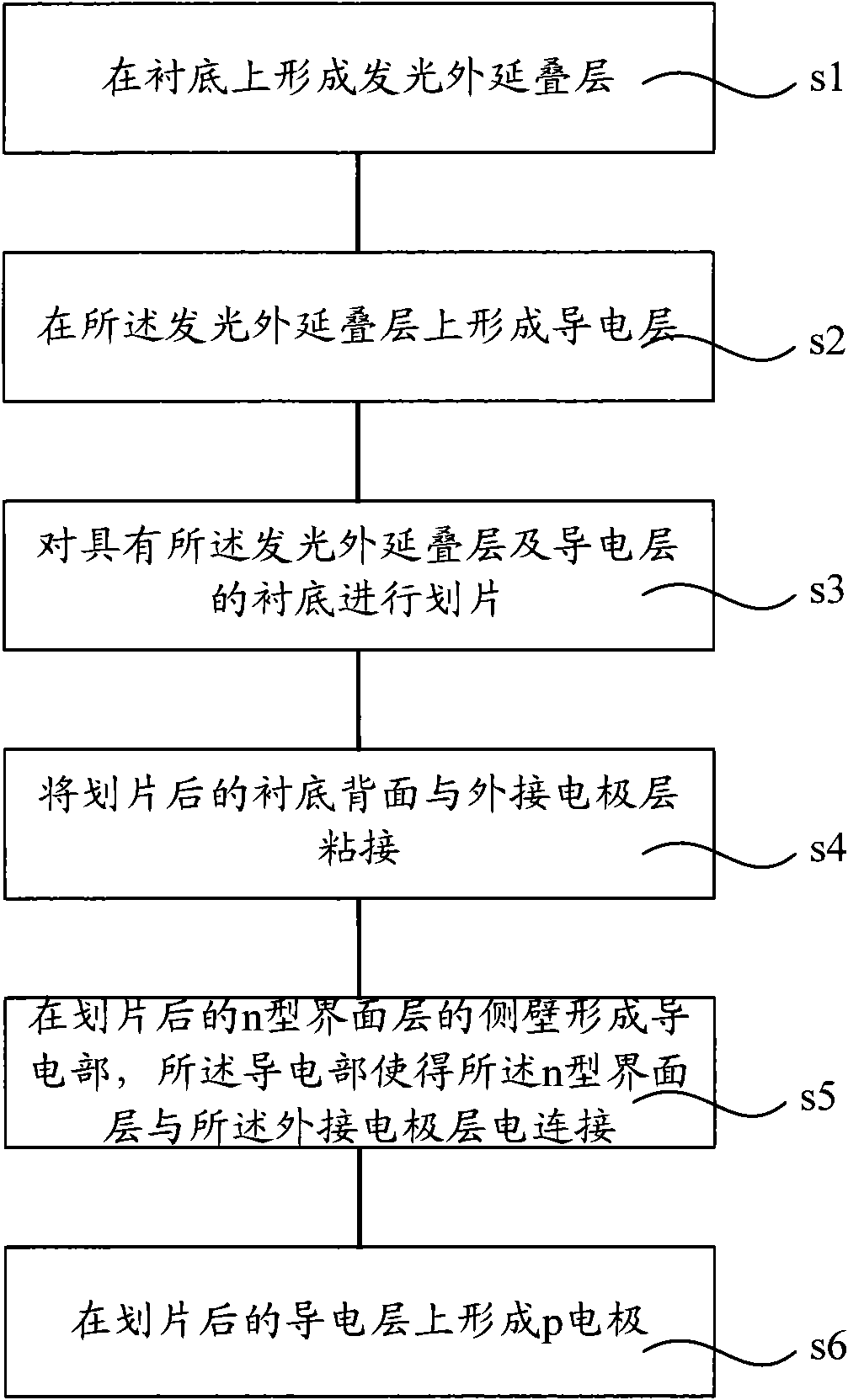

[0024] refer to figure 2 As shown, an embodiment of the light-emitting diode chip manufacturing method of the present invention includes:

[0025] Step s1, forming a light-emitting epitaxial stack on the substrate, which sequentially includes: forming an n-type interface layer on the substrate; forming a light-emitting layer on the n-type interface layer; forming a p-type interface layer on the light-emitting layer;

[0026] Step s2, forming a conductive layer on the light-emitting epitaxial stack;

[0027] Step s3, dicing the substrate having the light-emitting epitaxial stack and the conductive layer;

[0028] Step s4, bonding the back of the diced substrate to the external electrode layer;

[0029] Step s5, forming a conductive portion on the sidewall of the n-type interface layer after scribing, and the conductive portion electrically connects the n-type interface layer to the external electrode layer;

[0030] Step s6, forming a p-electrode on the diced conductive lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com