Vacuum high/low temperature environmental simulation electromechanical transmission mechanism comprehensive performance experimental system

A technology of environmental simulation and electromechanical transmission, which is applied in the testing of machine gears/transmission mechanisms, machines/engines, electric components, etc. It can solve problems that affect the accuracy of test results, difficulty in ensuring installation accuracy, time-consuming and labor-intensive problems, and achieve equipment adaptability Strong, easy to install and debug, and ensure efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

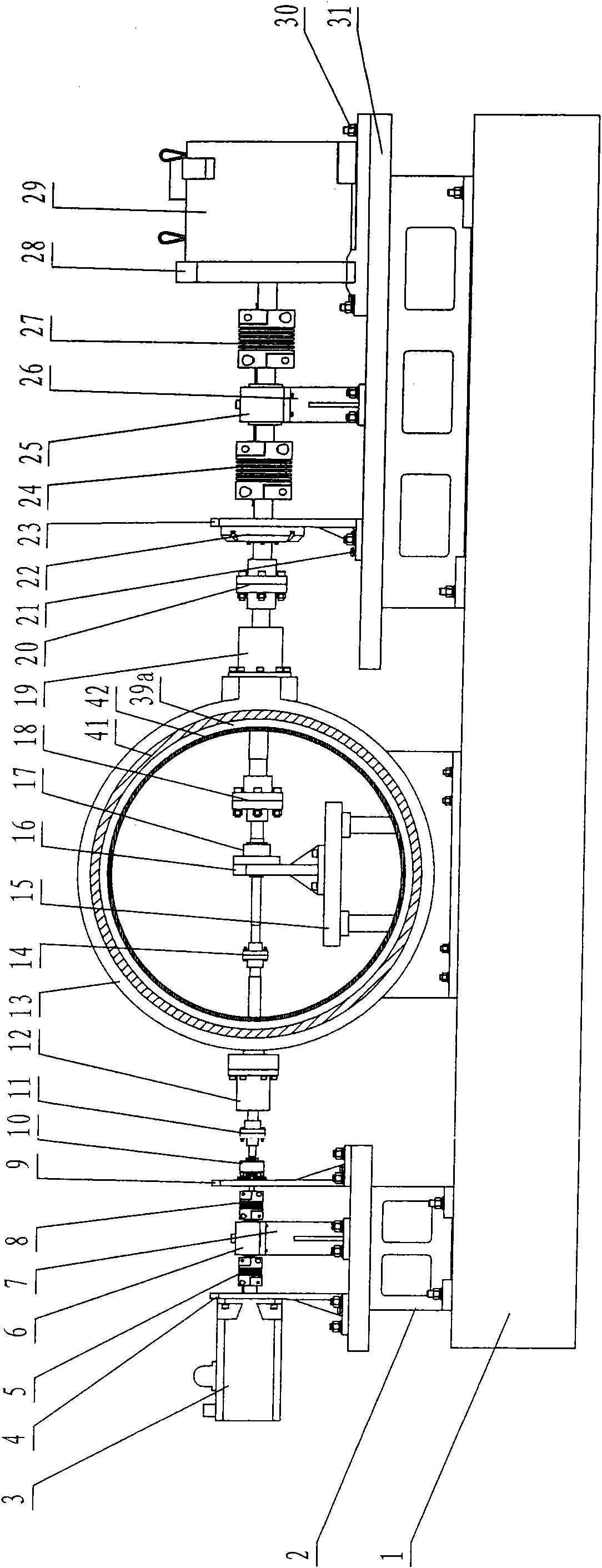

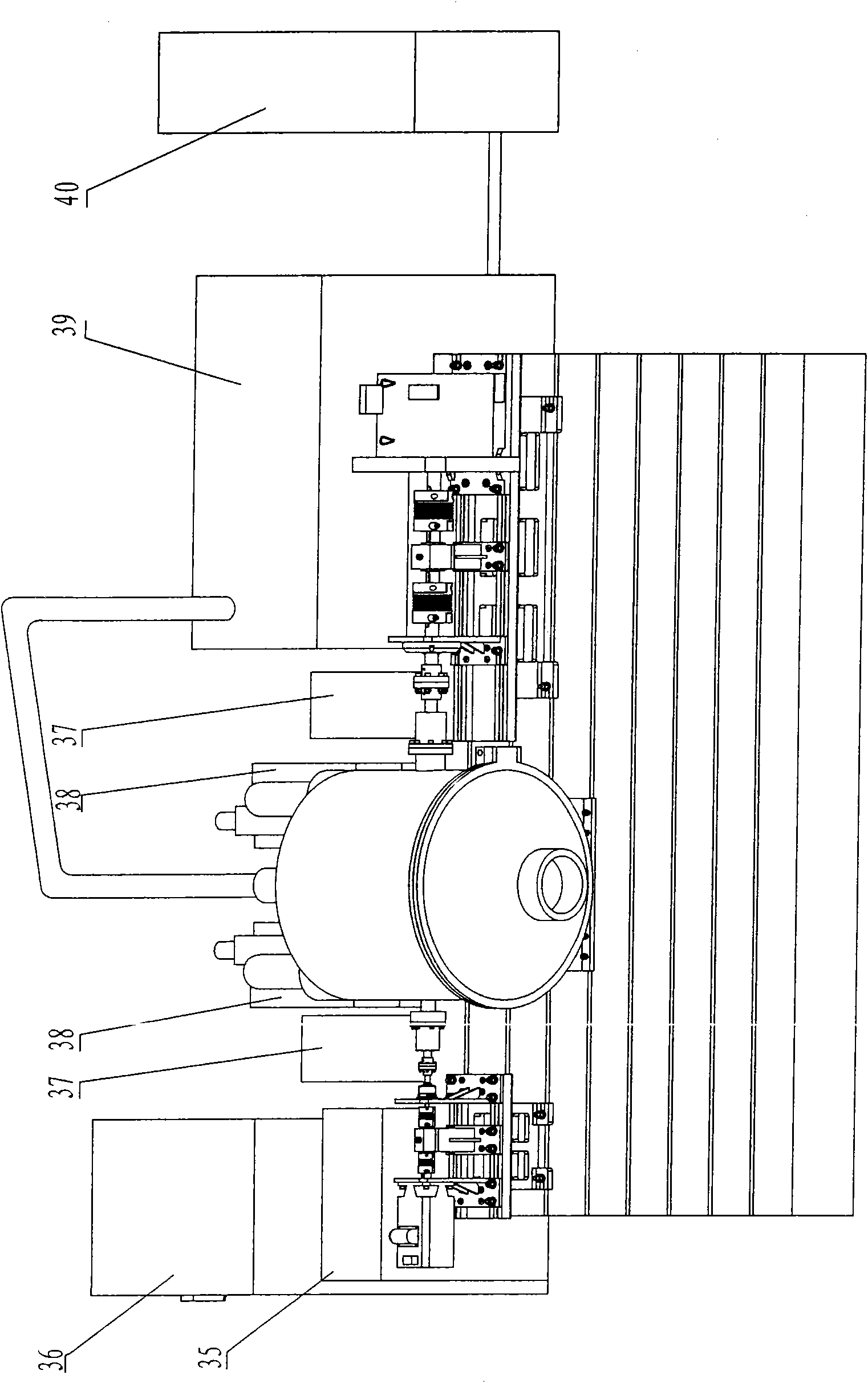

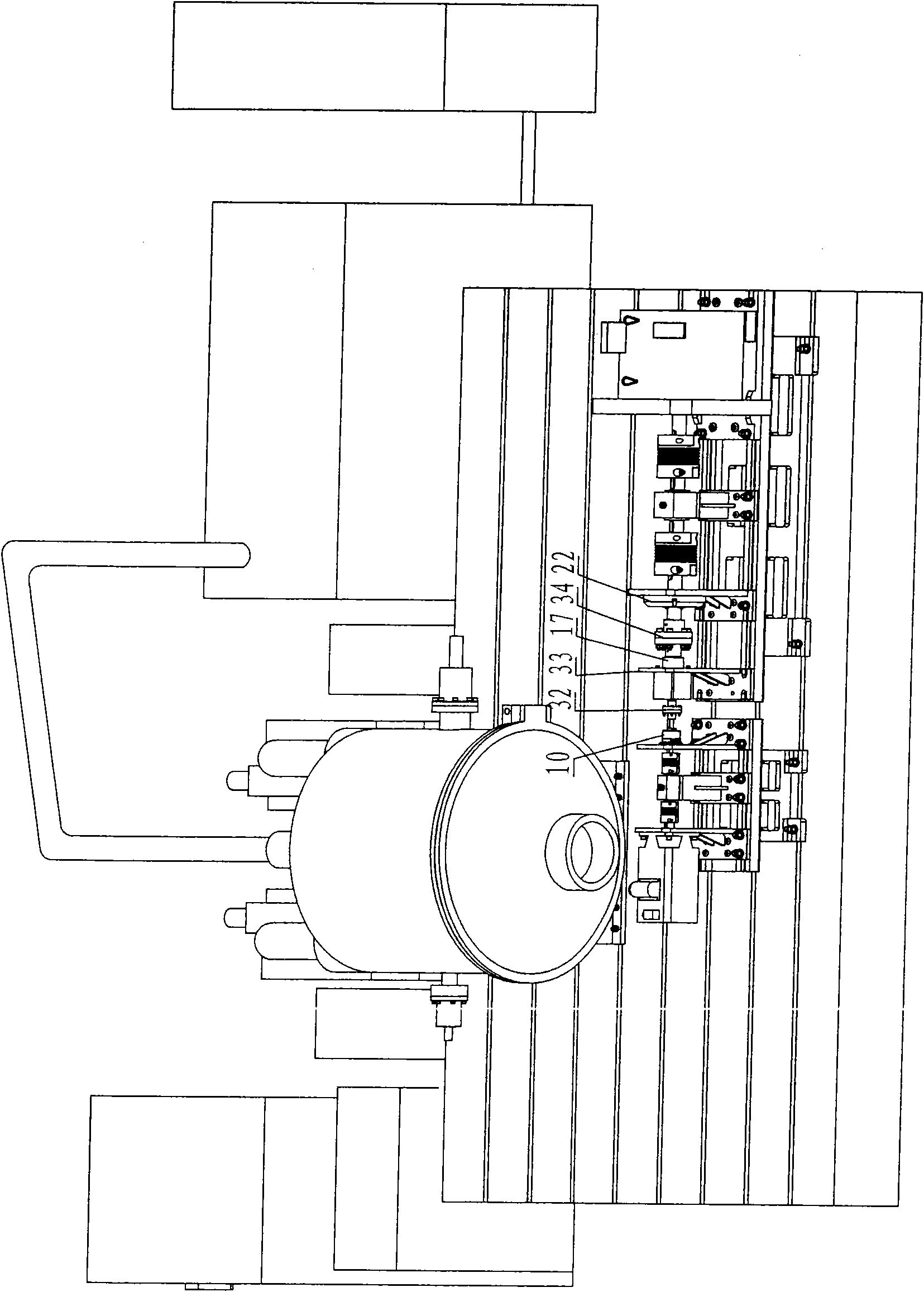

[0036] figure 1 It is a plan view of the general assembly structure of the comprehensive performance experiment system of the vacuum high and low temperature environment simulation electromechanical transmission mechanism in the vacuum high and low temperature environment experiment of the present invention; figure 2 It is a three-dimensional view of the general assembly structure of the comprehensive performance experiment system of the vacuum high and low temperature environment simulation electromechanical transmission mechanism in the vacuum high and low temperature environment experiment of the present invention; image 3 It is a schematic diagram of the general assembly structure of the present invention when it is tested in a normal temperature and pressure environment; Figure 4 It is a cross-sectional view of the inverted T-shaped groove of the present invention and a schematic diagram of the T-shaped groove with a bolt connection method; Figure 5 It is a schematic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com