Process for refining high-purity bismuth from bismuth-containing material generated from anode mud recovery

An anode slime and material technology, applied in the direction of photography process, photography auxiliary process, process efficiency improvement, etc., can solve the problems of frequent process splitting, harsh operating conditions, polluting the environment, etc., and achieve the expansion of application scope and good impurity removal effect. , the effect of low recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

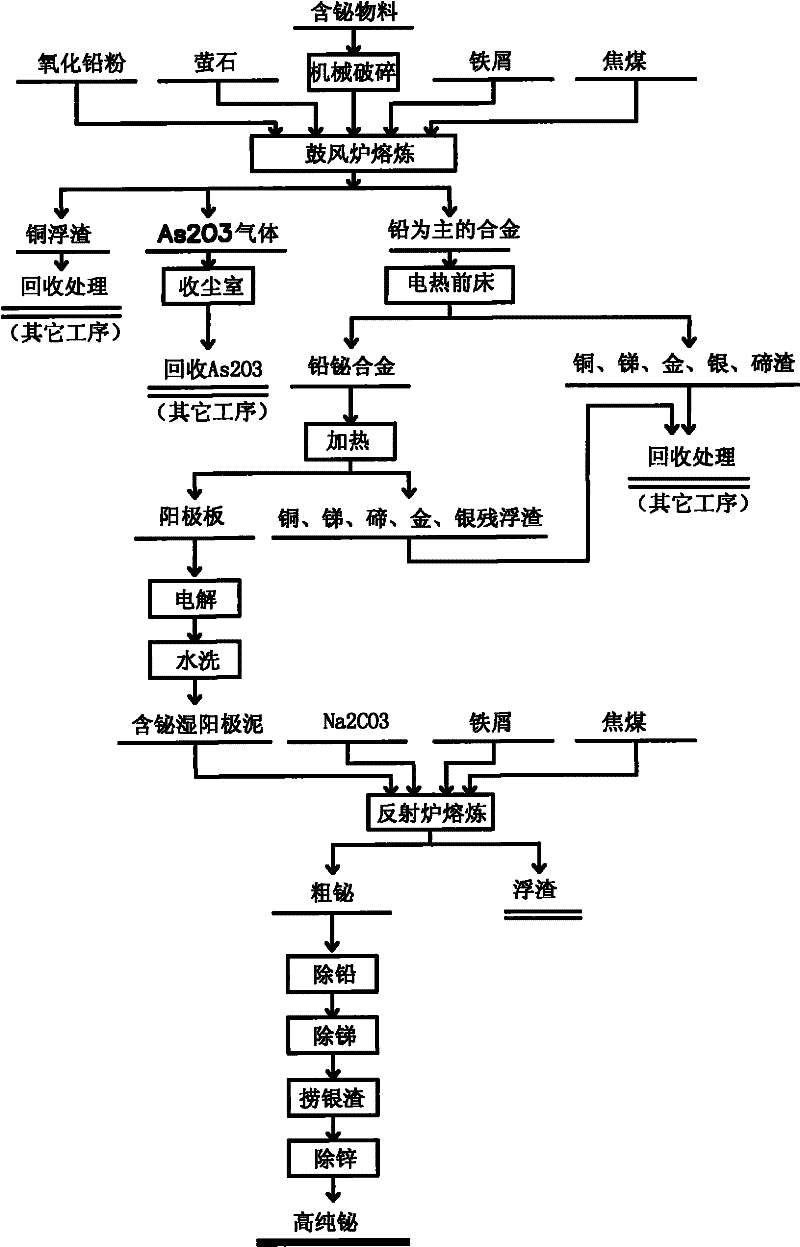

[0044] The following is attached figure 1 The production process flowchart, will describe the present invention in detail with specific embodiment:

[0045] As the technical solution for realizing the present invention is: the process of extracting high-purity bismuth from the bismuth-containing material produced by anode slime recovery is realized in the following steps:

[0046] a. After natural drying, the bismuth-containing materials are crushed into agglomerates or lumps, and the diameter of the agglomerates or lumps is controlled to 30-120 mm; the crushed bismuth-containing materials and lead oxide powder, fluorite, iron filings, and coking coal are calculated according to 100: (7~15):(12~20):(8~10):(30~45) After the parts by weight ratio is mixed evenly, enter the three-section blast furnace for reduction smelting, so that the slag and metal produced are at a temperature of 1300~1500 Separation at high temperature of ℃; at high temperature in the three-section blast fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com