Continuous production device of composite chlorine dioxide and technology

A technology of chlorine dioxide and production equipment, which is applied in the field of preparation and application of chlorine dioxide, which can solve problems such as inability to ensure sufficient and uniform mixing, limitation of application places, low purity and yield of chlorine dioxide, and improve the conversion rate of raw materials and the purity of chlorine dioxide, avoid equipment instability, and solve the effect of waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

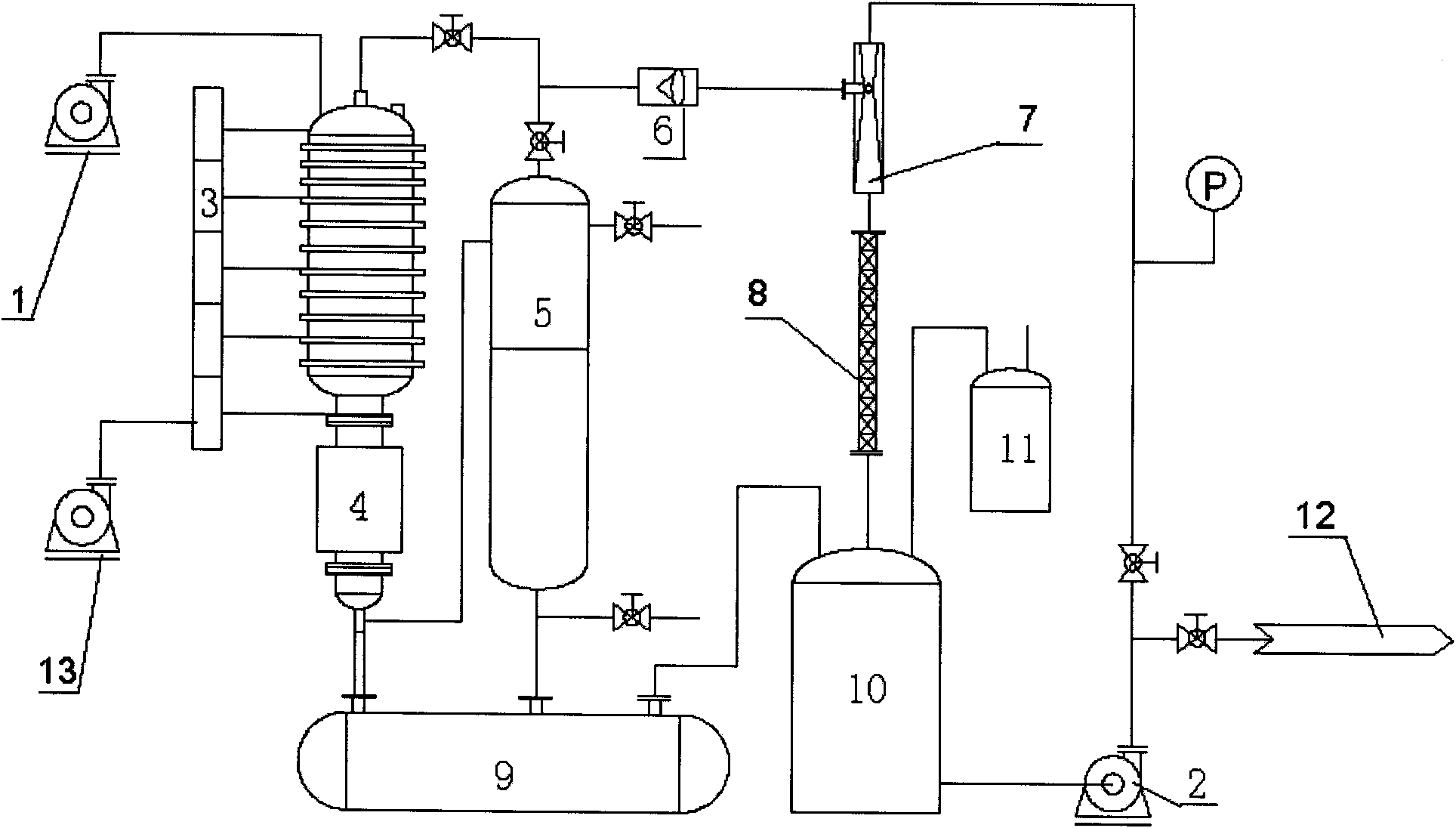

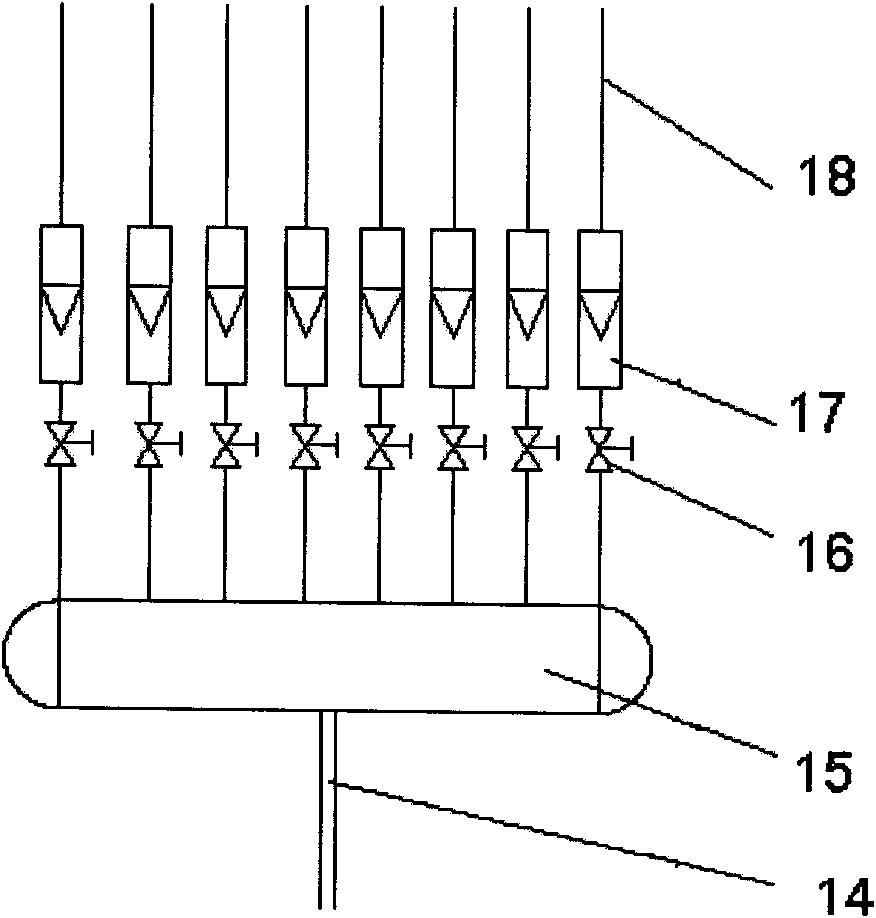

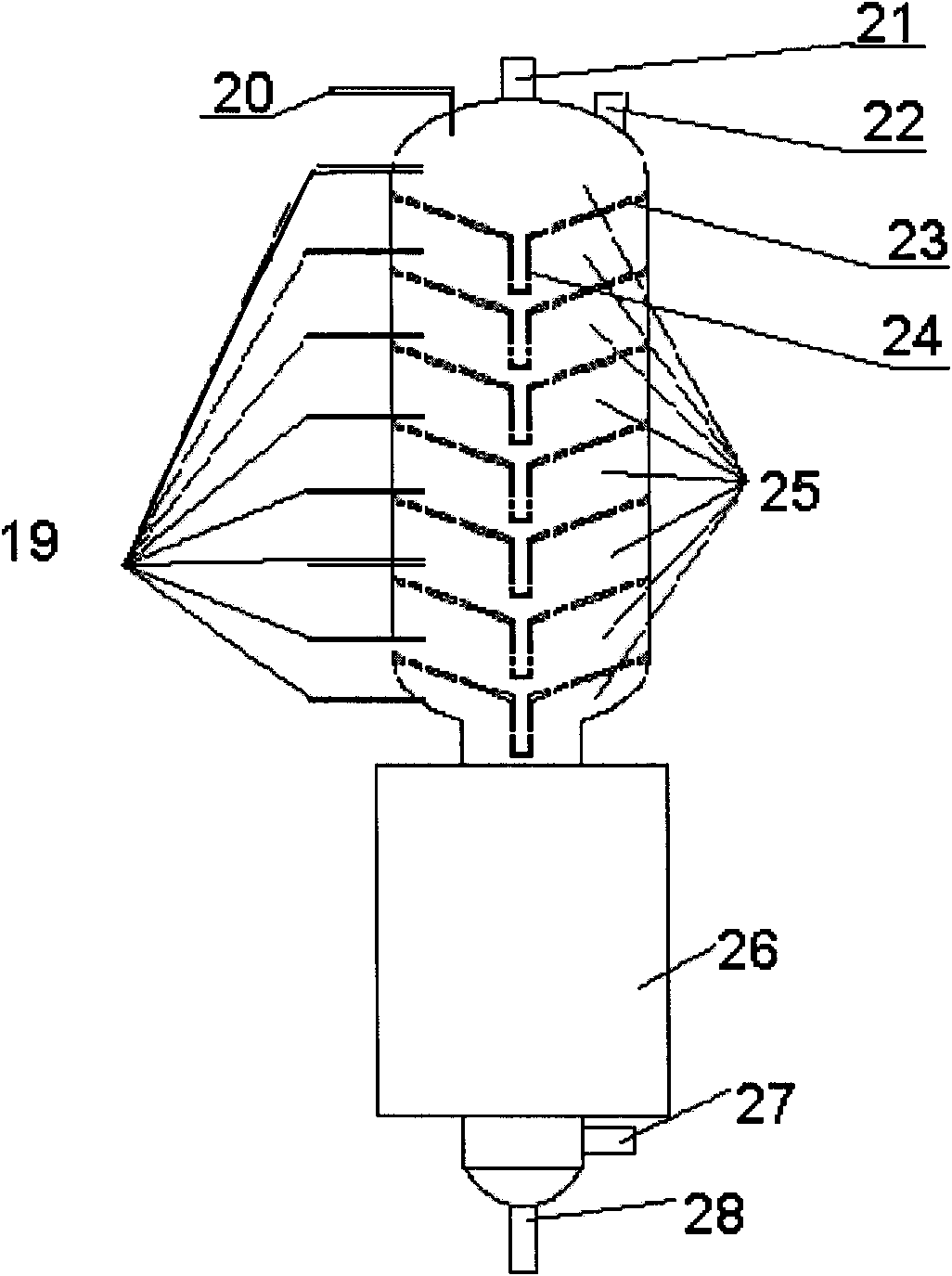

[0034] Embodiment 1, a kind of continuous production equipment of composite chlorine dioxide comprises chlorate delivery pump 1, hydrochloric acid delivery pump 13, multistage reactor 4, gas distributor 9, one-way valve 6, hydraulic injector 7, static mixing Device 8 and chlorine dioxide solution delivery pump 2, wherein the outlet of chlorate delivery pump 1 is communicated with the primary reaction chamber of multistage reactor 4, and the outlet of hydrochloric acid delivery pump 13 is connected with multistage reactor through hydrochloric acid distributor 3 4 reaction chambers at all levels 25 are connected;

[0035] The gas distributor 9 is connected to the air inlet of the multistage reactor 4, and the gas phase outlet 21 of the multistage reactor 4 is connected to the hydraulic injector 7 through the check valve 6, and the outlet of the hydraulic injector 7 is connected to the inlet of the static mixer 8 connected, the outlet of the static mixer 8 is connected to the wat...

Embodiment 2

[0048] In Example 2, the number of stages of the multistage reactor 4 is 6, and other equipment is the same as in Example 1.

[0049] Utilize above-mentioned equipment to produce the method for chlorine dioxide solution, concrete processing step is as follows:

[0050] 1) sodium chlorate is configured to concentration at the solution of 450g / l, and hydrochloric acid adopts concentration to be the industrial synthetic hydrochloric acid of 31%, and above two kinds of materials are used by chlorate delivery pump 1 and hydrochloric acid delivery pump 13 by volume ratio 1: The ratio of 1.4 enters the multi-stage reactor 4, wherein the hydrochloric acid enters the multi-stage reactor 4 through the hydrochloric acid distributor 3, and by controlling the difference in the amount of hydrochloric acid entering the six chambers, the reaction acidity of each chamber is controlled to increase the acidity step by step : The primary acidity is 3.0-3.2N, the temperature is 45°C; the secondary...

Embodiment 3

[0057] In embodiment 3, the number of stages of the multistage reactor 4 is 8, and other equipments are the same as in embodiment 1.

[0058] Utilize above-mentioned equipment to produce the method for chlorine dioxide solution, concrete processing step is as follows:

[0059] 1) sodium chlorate is configured to concentration at the solution of 540g / l, and hydrochloric acid adopts concentration to be the industrial synthesis hydrochloric acid of 31%, and above two kinds of materials are used respectively by chlorate delivery pump 1 and hydrochloric acid delivery pump 13 by volume ratio 1: The ratio of 1.8 enters the multi-stage reactor 4, wherein the hydrochloric acid enters the multi-stage reactor 4 through the hydrochloric acid distributor 3, and by controlling the difference in the amount of hydrochloric acid entering the 8-stage chambers, the reaction acidity of each stage chamber is controlled to increase the acidity step by step : The primary acidity is 3.0-3.2N, the tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com