Electric motor

A motor and motor shaft technology, applied in the field of motors, can solve the problems of waste, complex structure and positioning and assembly, weak anti-vibration and impact ability, etc., and achieve the effects of improving cost performance, low cost and simple production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

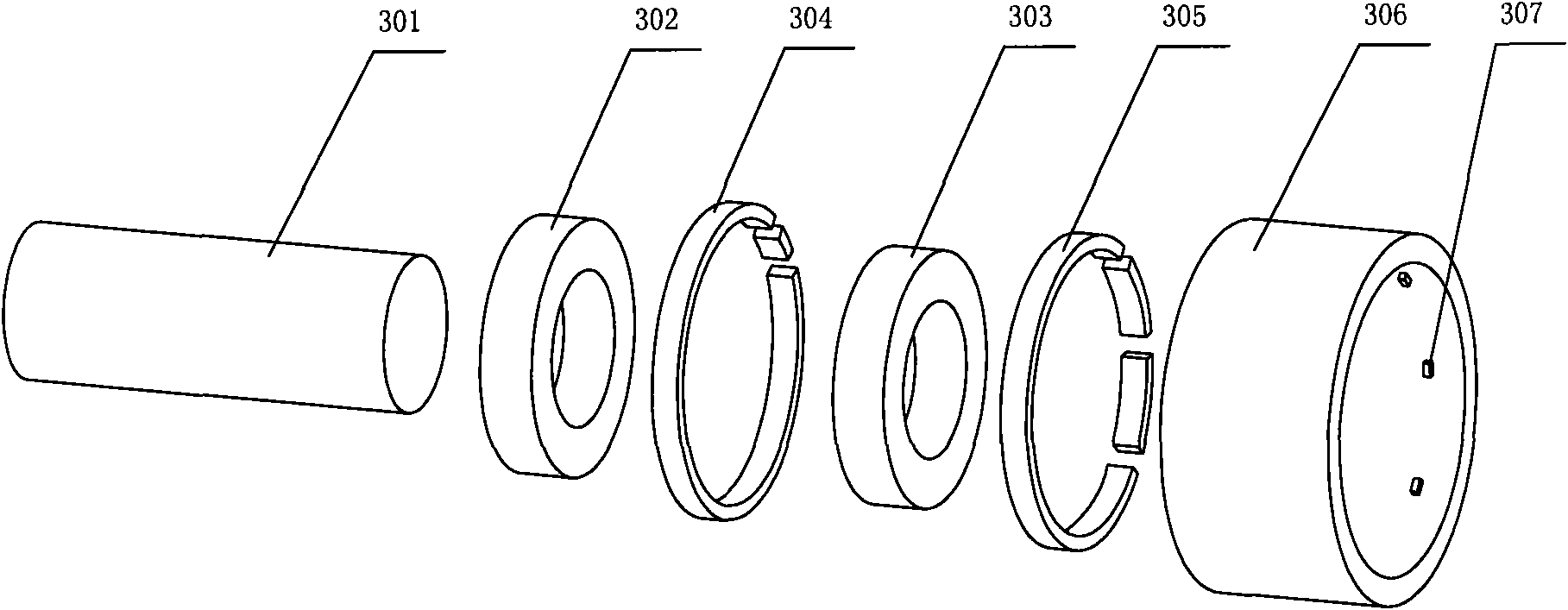

[0092] Embodiment 1 of the present invention provides a position detection device in which the first column of magnetic induction elements is provided with two magnetic induction elements 308 and the second column of magnetic induction elements is provided with three magnetic induction elements 309 .

[0093] Figure 9 It is a structural diagram of the first magnetic steel ring, the magnetic permeable ring and the magnetic induction element in Embodiment 1 of the present invention; Figure 10 It is a diagram showing the magnetization sequence of the first magnetic steel ring and the positional relationship with the magnetic induction element in Embodiment 1 of the present invention. There are 2 magnetic induction elements 308 in the first column corresponding to the first magnetic steel ring 302, i.e. m=2, with H 1 and H 2 Indicates that the two magnetic sensing elements H 1 and H 2 They are respectively placed in the two gaps corresponding to the magnetic permeable ring 3...

Embodiment 2

[0113] The second embodiment of the present invention provides a schematic diagram of four magnetic induction elements corresponding to the first magnetic steel ring 302 .

[0114] Figure 14 It is a structural schematic diagram of the first magnetic steel ring Hall element, the magnetic permeable ring, and the magnetic induction element in the position detection device of Embodiment 2 of the present invention; Figure 15 It is a diagram of the magnetization sequence of the first magnetic steel ring and the position relationship with the magnetic induction element in the second embodiment of the present invention.

[0115] Such as Figure 14 As shown, there are 4 magnetic induction elements 308 corresponding to the first column of the first magnetic steel ring 302, that is, m=4, and H 1 、H 2 、H 3 and H 4 Indicates that the two magnetic sensing elements H 1 、H 2 、H 3 and H 4 They are respectively placed in the four gaps corresponding to the first magnetic permeable rin...

Embodiment 3

[0119] The third embodiment of the present invention provides a structural diagram in which three magnetic induction elements are provided corresponding to the first magnetic steel ring.

[0120] Figure 17 It is a structural schematic diagram of the first magnetic steel ring Hall element, the magnetic permeable ring, and the magnetic induction element of Embodiment 3 of the present invention; Figure 18 It is the magnetization magnetic sequence of the first magnetic steel ring and the position relationship diagram with the magnetic induction element in the embodiment 3 of the present invention;

[0121] Such as Figure 17 As shown, there are three magnetic induction elements 308 corresponding to the first magnetic steel ring 302 in the first column, that is, m=3, and H 1 、H 2 and H 3 Indicates that the two magnetic sensing elements H 1 、H 2 and H 3 They are respectively placed in the three gaps corresponding to the first magnetic permeable ring 304 . The second row of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com